Leaderboard

Popular Content

Showing content with the highest reputation on 07/25/21 in all areas

-

The forum has been really slow lately, so I figured I'd try to add some content again. Recently I was contacted by a client to put together the ultimate Benelli M4 with a focus on reliability, and reduced perceived recoil. Cost is not a concern. The main goal was to have a shotgun built for home defense. So, with that said, here is the roughed out plan. The M4 is a 11707 model. It's an older version that has an aluminum trigger frame. The shotgun itself is brand new and never appears to have been fired. This is an 18.5" barreled model. Receiver Upgrades - Loading Port Modifications - GG&G Oversized Bolt Release - TTI Stainless Bolt Handle - FFT Reproduction Handguards Stippled by Tango Arms Stock Upgrades - Benelli M4 OEM Collapsible Stock - IWC MOE QD Sling Mount - Limbsaver 11011 Custom Fit with Noveski Adapter Plate Magazine Tube Assembly - Carriercomp Titanium Full Length Magazine Tube, internals polished - Carriercomp Magazine Follower (Old style with the red plastic indicator) - Carriercomp/Wolff Magazine Spring Trigger Pack - A&S Engineering Trigger Frame - FFT Trigger/Hammer/Disconnector Kit - FFT Shell Elevator - DMW Oversized Safety - Wolff Trigger Pack Spring Kit Sights and Optics - Scalarworks Sync Rail - Trijicon RMR Type 2, RM09 - 1moa dot size - Meprolight Night Sights Weapon Light Package - Surefire M600DF 1500 lumen output. - Impact Weapon Components Benelli M4 Light/Sling Mount - Surefire tailcap modified to remove the shroud Sling - BlueForceGear Padded QD Sling Refinish All parts are to be refinished in NP3 by Robar. Plastics will remain black. Items such as the lamp head on the weapon light will be painted to match the NP3 finish. The Trijicon RMR will be left alone. I received the shotgun on August 6, 2019. By August 7, 2019, the shotgun had been fully disassembled down to the smallest parts. Threaded parts were cleaned up chemically and with a wire wheel to remove any thread locker compound. Cleaning the parts up eats up a lot of time when done right. Even the bolt head is disassembled which is nearly an impossible task without some specialized tools. Getting that roll pin that holds the extractor claw out is almost an impossible task. You need a tiny curved punch in order to tap it out successfully. I disassembled his pistol grip stock so that the sling hardware and the installation screw inside the stock will all be plated in NP3 as well. As expected, the two screws that hold the rear sight in place are destroyed upon removal (the tip of the screw almost always breaks off.) I believe LPA stakes the top of the screw and creates that cupped shape. The nut that holds the front sight in place is a one time use item and will be replaced upon reassembly. This nut cannot be NP3 plated since it has a nylock insert. Small springs are bagged and tagged for reassembly. Some of them are confusing to know the difference by just looking at them. Springs like the one that holds the bolt handle detent and the extractor claw spring can be easily confused with ones from the trigger pack. I'll begin the loading port modifications once the A&S trigger frame arrives. I plan to go high, on the port, but not as high as Briley. I also plan to open the mouth more than Briley typically does. The entire loading port will be dehorned and there will not be a single sharp edge inside the mouth. Mine are all done by hand, so it is a little tedious. The owner supplied the carriercomp components, and the shipment from FFT arrived already. The handguards from FFT were mailed out to Tango Arms this morning. Will update with more as we move forward.1 point

-

1 point

-

1 point

-

So what you’re saying is either conform to someone else’s thoughts and standards or pay a price? Sorry but some of us still retain the idea of freedom of speech, expression and choice. A novel concept nowadays for some I guess. But I’m old school and as such I will NEVER live on bended knee. My 2cents………1 point

-

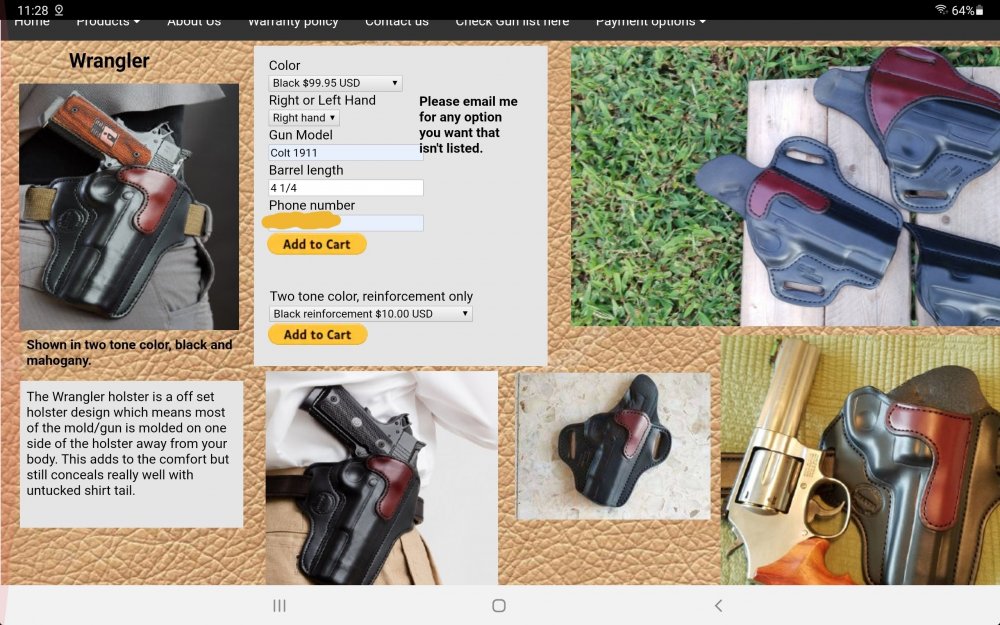

Oh, your words cut like a knife. ?? What's the revolver gonna do, start walking around shooting people? ?? Ever think perhaps there's a reason it's right there within easy reach? There is. But you're too caught up in your internet snobbery to consider it, sorry about that. It has to make life tough. And yeah the heat shield is plastic but it works and stays in place. I don't like the offerings on the market that provide a heat shield. Good enough for me. I don't own this shotgun as a status symbol, I want functionality. I'm not some wannabe operator so I don't use gloves when I'm just out having fun shooting it. The heatshield comes in handy. Looks like crap, but works. Again, sorry about your snobby lifestyle. I literally spend close to 16 hours a day in my car, 6 days a week. I clean it at the end of the week. I pull up by my burn pit, rake it out, then that evening burn it and drink a few beers. It's a routine. You don't ride in it so why do you care? Hopefullt this satisfies your holier than thou internet snob concerns. If not, or even if it does, you can still get bent. ?1 point

-

Finally got the bulk of my parts back from paint, a few minor mistakes to correct, but overall got me enough stuff to keep me busy for a few days. Finalized a H2O that has been taking forever due to Covid and Biden times. Just need to test and sight it in before it makes its way home. A second standard H2O should be finalized this week and taken for testing. The OD green M4 should get finalized soon for testing. The FDE/NP3 H2O has a few minor paint issues to correct, but I can assemble most of it in the mean time. The AR15 is absolutely beautiful. Wish it was mine! The AR10 parts pile in 6.5 Creedmoor should start taking shape too. I assembled a lot of weapon lights last night. I’ve begun having the lock ring that holds the rubber button in place Np3 plated. I thought they were plastic for the longest time. Turns out they’re aluminum.1 point

-

Got a few more of these H2O builds going on. With all the covid bullshit and run on guns this past year, it's taking a long time to first get all the parts wanted, then shuffle the parts thru plating. This one is still waiting on its plastics to be painted in OD green cerakote. I'm doing another one where everything had been NP3 plated, and now we're cerakoting the exterior in FDE. About the only things that will be black will be the rubber grip, rubber part of the buttpad, and the control buttons on the Trijicon RMR. Several more are in various states of waiting at Wright for plating.1 point

-

The front sight and rear sight from Meprolights will remain black since you can't plate the sights with their tritium lamps installed. There is a work around for this, but it is costly. You'd have to NP3 plate the OEM sights, then send those out to Tooltech to have Trijicon lamps installed. I think they charge a ridiculous amount, like 250 dollars. The hood of the front sight and the rear sight housing are going to be plated on this one. It will end up looking like this one I did a while back, but the Trijicon RMR's that are nickel boron plated aren't readily available anymore.1 point

This leaderboard is set to New York/GMT-04:00