Leaderboard

Popular Content

Showing content with the highest reputation on 10/01/21 in all areas

-

2 points

-

2 points

-

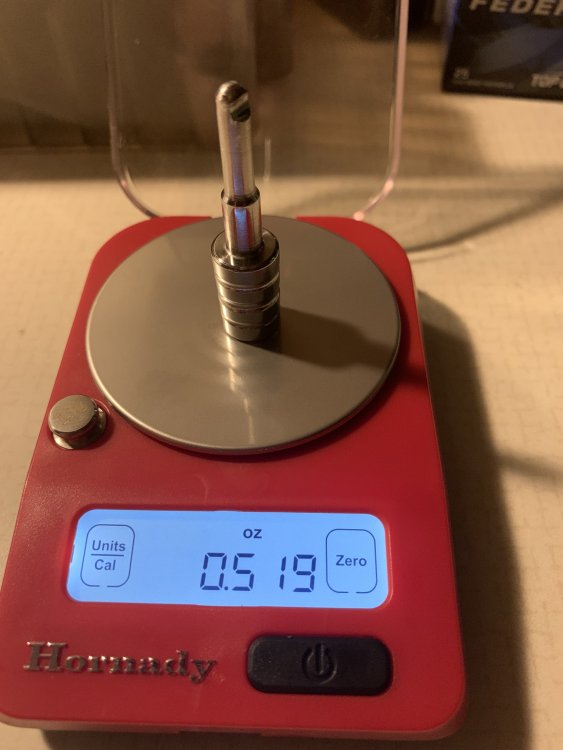

I didn’t really like the factory charging handle due to how skinny it was and the amount of play it had rotating and slop the “buttstock to muzzle direction”. I decided I could try to make my own on my mini lathe. First, I took measurements of all of the critical areas, or areas I thought were most important. On the first prototype, I discovered the most important measurement was the distance from the ball detent notch to the area where it tapered from .199” to .258”. On the 1st prototype, I made the notch too far down the shaft, causing the handle to be easily pulled out and or twisted since the ball was barley in the notch. The 1st prototype was also made from 4340. Didn’t like the idea of having to blue it and keep it oiled to keep it from rusting. The 2nd prototype and my final product were both machined out of 1/2” bar h900 17-4. Machined surprisingly well on my mini lathe using micrograin carbine tooling and medium speeds. The 4340 was almost too gummy and soft, and was chipping edges of my tools, which is probably due to lack of machining experience. Had zero tools break or chip while using the 17-4. Since I was making my own, my main goal was to eliminate play, and make the handle between .400” and .500” in diameter. The 2nd prototype was .500” in diameter and had zero play. Was machined from 17-4 as previously mentioned. My goal was to get a close match with the titanium cerakote by stone washing. (I literally used stones off of a dirt road and put them in a water bottle. Wrapped water bottle in socks, and had it go through the dryer’s tumble/no heat mode for about 8 hours. Came out looking really good, but didn’t match.) The handle was also heavier than I wanted it to be. I figured if the handle was too heavy it would cause feeding issues when using lighter loads. The main reason it was too heavy was because I only used a 5/16” drill, meaning there was about .094” of wall thickness. Way thicker than needed, especially while using such a strong steel. While this handle was heavier than the stock one by a decent margin, had no issues cycling what I’d consider medium target loads through my benelli m4, which only had around 50 rounds of buckshot through it at that point. With the 2nd prototype installed, I shot 50 fiochhi target loads, 30 Federal LE slugs, and 50 rounds of Winchester SuperX buckshot with 0 malfunctions which surprised me due to how heavy it was. My final product weighed a good amount less due to the handle being around .450” in diameter and me using an 11/32” bit. This made wall thickness somewhere around .055”. Still more thick than necessary for what this is being used for. Since the stonewash didn’t have the effect I was looking for, I figured I’d give it a decent polish to match the TT lifter I have on my gun. I really like the look, and the polishing didn’t make it any more slick than the stonewash finish. I also rounded the end of the handle making insertion easier than previous designs. Also makes marring the finish on the barrel less likely when using the handle to disassemble the piston assembly. As you can see by the pictures, I only put one notch on the charging handle. I don’t know why the factory one has three notches, but that is one of the things that causes the handle to have slop. Using only one notch made the handle really tight and have zero slop in any direction, while also still being easy enough to remove by twisting and pulling. I also made the smallest diameter part of the shaft +.002” compared to the factory .199”. This eliminated the “front to back slop” I mentioned. If anyone is interested in the measurements I used, send me a DM and I’ll send you a picture of my drawing I made of the factory handle and it’s measurements and my handle and it’s measurements. Thanks for reading, Bryce1 point

-

She looks good and definitely looks like she has some bully breed in her. Good on you for adopting her. A lot of people won’t touch a dog w/ any pit bull breeding in them, which is too bad. They are wonderful dogs when properly bred, raised, trained and owned.1 point

-

Her name is chips. We rescued her about 6 months ago from the Kansas humane society. She’s about a year old now and is a spaz, but a good dog. We think she is a pit bull/lab mix. I try to always have her in the background of my gun pictures to add something special to the picture. She does like to run off after deer that sometimes come into our backyard though, hence the cable we have to use now. Lol1 point

-

1 point

-

Sheesh! Thats a good looking gun! GLWS ?1 point

-

Very nice! I’ll probably get the M1014 as you have. I like the flag, the stock and I have no interest in changing chokes because this will not be for hunting or clays so the fixed choke is perfect. I will also get the 3 position buffer tube so I can collapse the stock and 7 round mag tube. With those two items, what other parts did you change to maintain 922 compliance?1 point

-

1 point

-

I'm not sure how lenient Benelli is with their warranty stuff, but I wouldn't have taken a file to anything. Should have contacted them and sent it straight back...1 point

-

The M4 is pretty drop safe. I was concerned about the design years ago. So I unloaded it and repeatedly bounced the gun on the carpet in various angles to try to get the hammer to fall. It never happened. You’d need to throw it hard enough for the trigger to be pulled in order for the hammer to drop I don’t think you could shock the hammer to get past the trigger hook or the disconnector if it rebounded enough. What I use the safety. Round in the chamber, magazine topped off. I don’t mess with ghost loading since I’ve seen it cause malfunctions. I use a larger DMW safety that I can feel poke my trigger finger when the safety is engaged. It’s instant feedback to know its condition. I also trim 1.5 coils from the spring so that I can press the safety without breaking my firing grip. It’s still firm to press, but not factory straining firm. As a certified firearms instructor, I should add some comments about safe storage. I’d urge everyone to store their firearms in some kind of safe even if you don’t have children. A cousin of mine when he was 3-4 went to someone’s house who didn’t have children and they had the shotgun leaned against the back of a door. No one thought of the gun and he went and grabbed it being young and not knowing any better. He pressed the trigger and the shotgun discharged thru the roof right next to his head. He was fine, but it could have easily not been. The only victim that day was the sheet rock in that guy’s trailer along with his pride. There are a bunch of cool high speed locking systems out there now with biometrics and back up PIN numbers. They have them for rifle and shotgun storage now, not just pistols. They’re not meant to protect against theft, they’re meant to keep the firearm out of unauthorized users’ hands and keep them accessible to you if needed. From a training perspective, if the firearm has been out of your immediate control for any length of time, should you trust that it is still in the condition you left it in? No one wants to spend a couple hundred bucks on a lock box. Most of them suck anyway, but what if you got one that presented the pistol grip to you so you could draw it easily with the trigger guard covered? Sweeping a loaded pistol off a night stand in the dark can be a safety issue. Did the cat jump on it and move the way you position it? Depending where you live can add another layer of culpability if an unauthorized user gets ahold of one of your firearms. Even if they’re a burglar. Having at least this second layer of protection will help keep you out of trouble when LaShawn steals your gun and smokes the cashier at the Stop & Rob.1 point

-

Benelli states slugs should not be shot in a choke tighter than IC. The shotgun ships with a modified, which is tighter than that. I know people have shot slugs through the modified choke and I have not heard of any issues. A modified will deform the slug slightly and that could cause a lot of stress on the choke and end of barrel. I use a Light Modified in 3-gun almost exclusively. It is right between an IC and Modified. I have shot many slugs through it and have not had any issues. The LM is a good compromise between ability to shoot slugs when needed, and the ability to knock over a plate at 20 to 25 yards with 7-1/2 shot if needed. Mike1 point

This leaderboard is set to New York/GMT-04:00