notrabmas

-

Posts

48 -

Joined

-

Last visited

Posts posted by notrabmas

-

-

The tactical one (pistol grip, non collapsible).

-

Hi everybody,

Does anyone know how much the stock weighs for the Benelli M4? I'm shipping one out and need to know how much it weighs.

Thanks

-

What was the problem?

-

Do you have a new top rail installed? You may have not taken the washers out of the OEM rail and put them in the new top rail. This caused the 5 screws to protrude into the receiver and catch and lock the bolt back. Happened to me when I installed my Sidearmor Mod 3.

-

As I posted earlier, I'm using an A.R.M.S. #31 mount on the OEM rail with no issues so far. AFAIK it's just the LaRue that is incompatible with the OEM rail.

I've heard that most optics won't work with the OEM, but I could be wrong. That's why I thought everyone changes theirs. I guess YMMV though.

-

SD - is it Larue Tactical LT661 mount?

BTW Probably will not be the same when mounting on the OEM rail? I think yours is aftermarket - carriercomp?

It is the LT661, but optics don't work on the OEM top rail. You have to buy an after-market one (Carriercomp, Freedom Fighter Tactical, or Sidearmor).

-

Wow, that actually makes a lot of sense.

-

-

What was he saying that was a nuisance I remember watching his videos and I saw that he had an account on here that was banned. Or is he now "he-who-must-not-be-named"?

-

-

I paid about $5.00 for a box of 5.

-

Yeah I do, $50 sound good?

-

Sadly it's just the regular stock. I wish I had a collapsible stock haha. I'm out right now, but I can post pictures soon.

-

I have a used Benelli M4 pistol grip stock for sale. Was only on my shotgun once when I fired it. Looks brand new and doesn't have any scratches or wear to it. Looking for offers.

-

Ahh, ok. Thank you!

-

So should I put lube just there? Or all over it?

Yes, it will break in with use. Lubricant helps a lot.

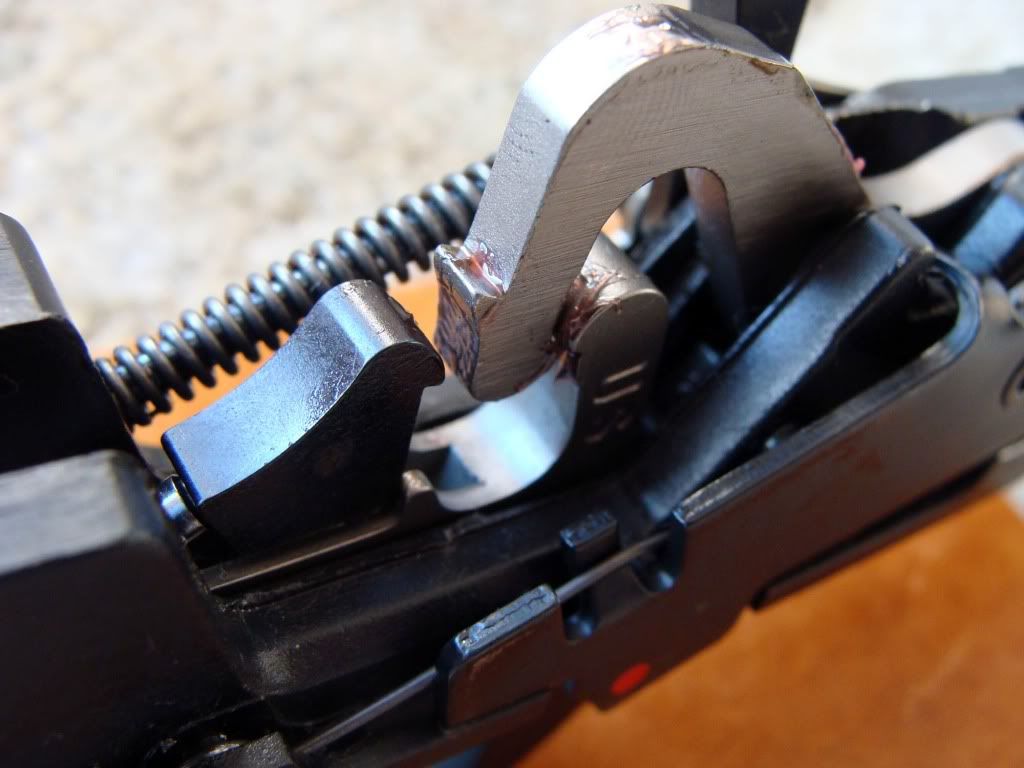

in this shot, it shows the hammer hook engaged on the trigger sear. To the left is the disconnector. When the hammer is cocked, and the trigger is held to the rear, the hammer hook is forced against the disconnector until the spring loaded disconnector pushes to the rear and captures the hammer hook. The hammer remains on the disconnector until he trigger is released. You'll hear an audible click when it disengages the disconnector and engages the trigger sear.

Apply oil on the disconnector where the hammer hook makes contact.

-

I found out about it when I took the trigger group out. That makes a lot of sense on why it is stiff; the gun is pretty much brand new and has had about 15 rounds through it. Besides oil, will shooting the gun loosen up the disconnector? What about cocking the bolt back while the safety is on to loosen it up?

Try creating this problem with the trigger group pulled out of the weapon. Cock the hammer with your thumb in safe and fire. Try pulling the trigger in fire, pull and hold the trigger to the rear, and recock the hammer. This will engage the disconnector until you release the trigger.If the disconnector is what is causing the hang up, try some oil on it. Sometimes a new gun just needs broken in. I recently worked on a new 11707 that was really stiff in the trigger group area even after I swapped the fire control out for a FFT set. After oiling and working the action for a while, it smoothed out significantly.

Oh yeah, don't let the hammer drop when the trigger group is out of the receiver. You can hold the hammer with your thumb to allow it to move forward.

-

I found out the reason mine is stiff is because when the safety is on, the thing that hold the hammer when it's cocked doesn't allow any movement since the trigger can't be pulled. When the safety is off though, it allows it to move so that the hammer can be cocked. I hope this doesn't mean mine has a problem.

Umm, I guess I'm trying to say when I pull back the bolt to load a shell (the hammer is foreard) and the safety is on, it's slightly stiff when the bolt reaches the hammer. When the safety is off, I can pull the bolt back (with the hammer forward) with no resistance. I just lubricated the gun yesterday too. -

Umm, I guess I'm trying to say when I pull back the bolt to load a shell (the hammer is foreard) and the safety is on, it's slightly stiff when the bolt reaches the hammer. When the safety is off, I can pull the bolt back (with the hammer forward) with no resistance. I just lubricated the gun yesterday too.

-

Strange, mine is kinda stiff when I try with the safety on.

Pull the bolt to the rear to chamber or eject a round? Yes, the bolt should cycle freely regardless if the weapon is on safe or fire. -

Huh, that makes sense. One more question that's unrelated, you can't pull back the bolt if the safety is on, right?

Lift the elevator and place your thumb on the inside of the shell stop. This is the part that actually holds the rounds in the magazine. Press the front of the shell stop inward. You may also need to press the shell into he mag tube to relieve tension. As the shell stop pushes in, the shell will eject, pushing your thumb out of the receiver and the round will fall into the palm of your hand. On some weapons, this is harder to do than on others. -

I've read that in the manual, but where is the button?

-

Hi,

I have an M4 and I've fired it and all that, but how do you unload the rounds from the tube? I know on a pump you rack the slide, but on the M4 do you rack the bolt instead?

-

Haha, that was me. Did you put in the stock washers OP?

Sidearmor is a good thing to check. There was another user on here that did not put the stock washers from under their stock rail under their sidearmor and the screws were then protruding into the receiver and jamming up the bolt...Remove your bolt and see if there are and scratches on the top of it for one... feel in the receiver were the screw holes are and make sure there is nothing protruding even a little.

Benelli M4 stock weight

in Benelli

Posted

Ok thank you! I thought it was around 2 lbs.