M1014

-

Posts

2780 -

Joined

-

Last visited

Posts posted by M1014

-

-

-

-

wow,cool topic,been a way a while,love those M1014s,awesome shotgun,man, if I couldn't afford a Benelli m4 and this m4 clone is avalaible,I would buy it,even if it works for just a little while because ''something is better than nothing'',I bought a chinese trench gun clone last year cause I could'nt afford a real one.it broke on me 6 months later, very bad ,it was so bad that the 1897 smiths would'nt touch it,another smith said''ditch it''so I sold it and used the money and then some to buy another gun,so it worked out pretty good,it didn't seem like it at the time,the gun I bought was just meant for me, ,heck of a journey to end up purchasing my favorite type of shotgun, a Benelli, I wish all of you a good day and happy shooting.

-

2

2

-

1

1

-

-

you can google ''Italian proof marks'' and your answer will be there,I love those 121 m1s,got one too.

-

On 3/26/2019 at 2:20 PM, Skypirate7 said:

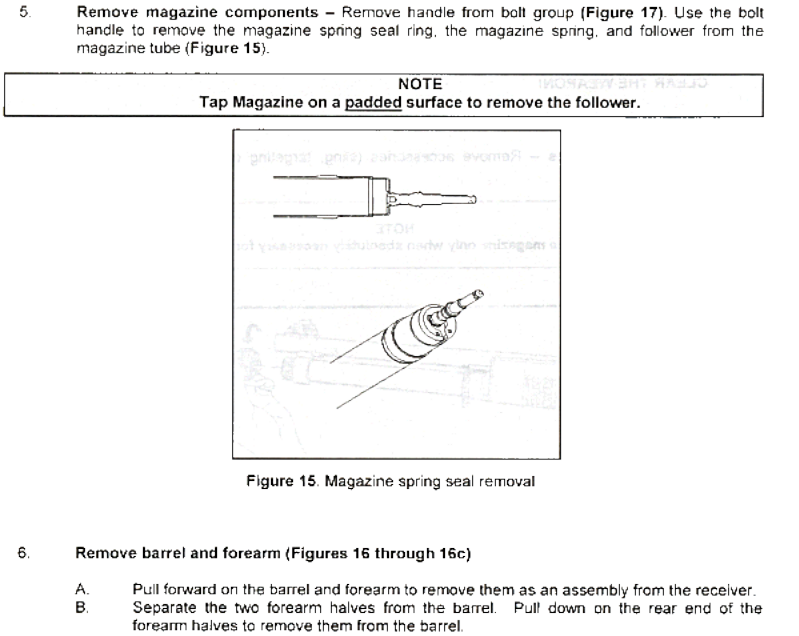

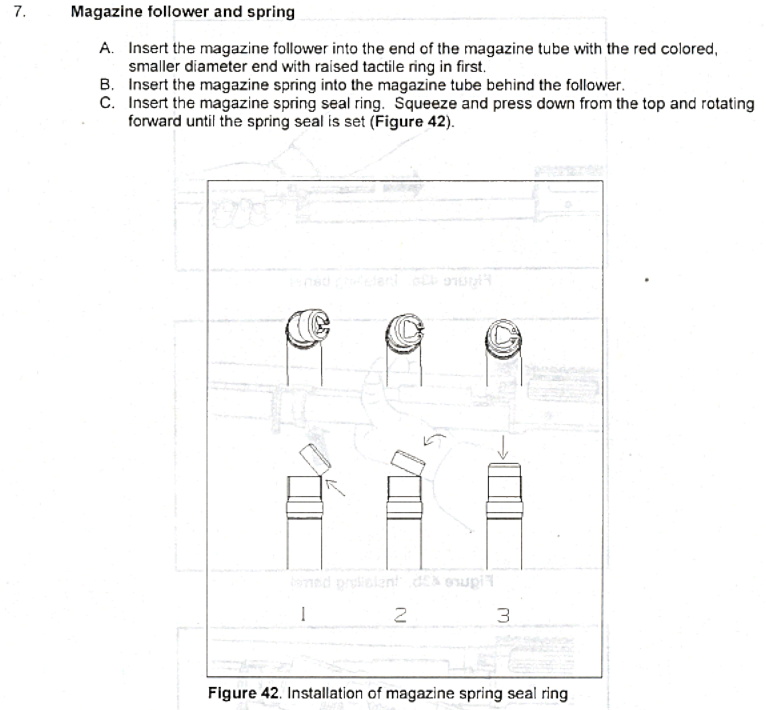

that sad for my memory,I had forgotten all about that military manual method and the worst of it is that I own one of those manuals,age is catching up to me,,thanks for the reminder

-

-

-

thats an english ,,,field stock has a grip

-

I wish I hadn't read this post ;-)

me too,now to get some overtime

-

look at the date,,oh my:https://forums.benelliusa.com/showthread.php/12928-M1014-M4-heatshield?highlight=benelli+heatshieldThis is the one I purchased from eBay, it's still out there available... https://www.ebay.com/itm/TRINITY-Aluminum-Heatshield-Matte-Black-Anodize-Finish-For-Mossberg-590/152356107719?hash=item237921b5c7:g:EvAAAOSwB4BaIegK:sc:USPSFirstClass!90250!US!-1and from there website... http://www.trinitysupply.com/12-Gauge-Shotgun-Heatshield-p/8.htm

That is the one I purchased from them, mine didn't look like the picture on eBay it is the one in my pictures. 14 day money back guarantee if you don't like it.

-

there making those type of heatshields in metal too? they used to be plastic in the past,who makes them?,,PS:nice jobFinished adding a heat shield to my M4. I used some Fireflex Seal tape from the hanger where the steel heat shield touches the barrel, for scratch protection.Mounted very sold, no movement at all, 50 rounds through her and no problems or looseness.

Heat shield added 2.5 oz, Titanium Magazine was a minus 4.4 oz for a total weight of 8.08 lbs and 8.13 with the breach installed.

[ATTACH=CONFIG]3554[/ATTACH] [ATTACH=CONFIG]3555[/ATTACH] [ATTACH=CONFIG]3556[/ATTACH]

-

hope he is listening,,good pointersWas the weapon cleaned and lubricated and properly assembled/verified?Does the ejector move freely but with reasonable spring tension present?

can you cycle the weapon by hand, with no ammunition, and feel any meaningful binding after the first cycle which sets the hammer?

do the gas pistons move smoothly and easily through their operational travel, and when removed and rolled across a true surface , do they appear straight? Are the marks they have made on the carrier face roughly comparable to one another, or does it look as though one is impacting significantly harder?

Does the extractor have full range of motion with proper spring tension, and is it's contact edge even and appear without defect?

-

-

Thank you,I'll check it outDon't know if this will help, but Matchsaverz does have a youtube video showing their product in operation on a Benelli M4. It doesn't show the installation, but maybe watching the video and viewing the location that they used might help.They also have a video showing some of the installation process of installing a Matchsaver on a Benelli M2. Although it doesn't give any definite information pertaining to the M4 it does point out how to choose a location and also mentions that the Matchsaverz can be installed using velcro pads with adhesive for a temporary location, or to test a location to determine if that is where you want to eventually permanently install it.

-

just viewed taran tacticle pics,there m4 has one,theres no you tube vid on it,they are magicians' I guess.

-

I got a matchsaverzz for Christmas and attempted to install it on my M1014,,''no go'',tried different locations on the forend,the gas piston tube is in the way,wrote them on facebook,we will see if they respond,might call them,patched the hole in my forend. ''so much for experiments''

-

I love how you call it,the ''old school M1014'' it just blows me away,lol lol,stay well friend

I've done a few of them. I don't like doing them though since they take several hours to do by hand. You then run in to refinishing issues afterwards. The only real risk area is around the shell stop release pin. You don't want to thin the material too much to weaken the latch. Removing material by hand is slow going, so there isn't a whole lot of risk of overdoing it.

I use a large flat file to shape everything before finishing them up with a dremel. I then enlarge the mouth of the loading port by grinding it out at a steep angle on both sides. This adds about half an inch of additional room inside the loading port area. I polish everything heavily with an abrasive polishing wheel. By the time I'm done, the edges are butter smooth and there are no sharp angles. Everything is radiused over including the front of the loading port.

You have to pick a transition point how you want the rear of the loading port to blend in with the front. I do a polished out angled taper.

Using one of the TTI or FFT elevator's helps improve the loading.

It's best when the receiver is being refinished. I have someone's coming back in a few weeks from Robar. We removed the crappy painted on Cerakote H2O finish, and had NP3+ applied. I'm sending a old school M1014 for NP3+ for a client in a few weeks too. That should look interesting on a flag model.

-

-

very awesome set up,I haven't forgot about the telescopic stock limb saver pad set up you offer,gotta get one.

-

read the other post,now I understand,its a california thing,dig the cheek piece.

-

I own a couple of SBEs,there fun as sh%t,,I clean mine every time I go out,somewhere is a statement about very lightly lubing the rotating bolt edges and locking lugs,it said to help prevent the bolt from partially engagging.I got a limbsaver recoil pad on it for the 3 -1/2s,hope this helps.

-

Minimal market volume is the main issue. Cost is also an issue. People going full out building up M4’s end up spending a lot for marginal improvements. I’ve had people drop 4K outfitting these shotguns. That doesn’t count the cost of the weapon itself.

We do have quite a few companies that specialize parts for this platform. Ava Tactical was built and designed here. IWC is now supporting the platform. Scalarworks was specifically made for us. Carriercomp and FFT have both been providing product for years. I’m happy to see companies like A&S step in to the market and approach products I didn’t think anyone would ever try.

We do get crappy brands come through and try to get in to the market. I don’t blame them for trying but wish they would provide a product that is equal or superior to OEM. Some may remember my fights with ATI when their owner got butt hurt over my comments about their product. When given the opportunity to send their item for unbiased testing on my test bed M4, they refused even though I would have sent it back after the reviewing process. TTI has had hits and misses.

This forum rum is a lot slower than it used to be. In the past you’d come daily and find a dozen new threads. Lately you’re lucky to find a single one with activity.

aaahhh the old days,when this forum was the happening place to be for the M1014/M4 owners , for many years,,good times ,good memories.

-

very cool build,I'm taking notes. thanks

-

as an owner of a M1014,I can say the that it does digest all ammo,there may be some breakin time for a new gun if any,read your owners manual,lighty oil and have fun,''congrats on your future Benelli''

practical/ipsc shotgun for sale on the broker

in Shotgun Sports

Posted

Benelli M1 Practical 3 gun/ipsc Package - Semi Auto Shotguns at GunBroker.com : 917421719