srg433

Members-

Posts

8 -

Joined

-

Last visited

Recent Profile Visitors

The recent visitors block is disabled and is not being shown to other users.

srg433's Achievements

Junior Member (1/3)

2

Reputation

-

Yeah, it was surprising to me to learn that reducing the length of the spring in a 5 round mag tube actually led to increased energy on the follower. If I were to guess, it likely because of the unnatural shape of the spring leading to excess energy applied to the sides of the mag tube rather than straight down on the follower. For 7 round mag tube, I live in MA, which makes it complicated... Two extra rounds for me aren't worth being in some gray area of the law where people keep arguing what a "feeding device" is...

-

I finally got more time to get to the bottom of it and happy to report that the problem is now resolved. TL;DR I have 5 round mag tube and I replaced the spring with Carrier comp one AND shortened it to 20'' (most important part). Additionally, I polished the carrier latch with my Dremel, this step is likely optional as the spring's role is more important. The longer version is below. More details: After cycling many more rounds through it and replacing the spring with new OEM one, the number of FTFs reduced but was still at about 3-5% for some specific ammo brands. Since reliability of a weapon is the most important thing, I wasn't satisfied with that. I wasn't able to replicate the issue with A-Zoom dummies or other "no-name" dummies and live fire gets expensive really quick. As per the Internet anecdotes, Fiocci dummy rounds have more FTF issues than the others, so I order them. Once the dummies arrived, I could clearly replicate the issue with FTFs happening 30% of time. It was great as I finally got a way of reproducing the issue reliably and with no extra expense for live rounds. As for any engineer's satisfaction, the ability to reproduce reliably is like 50% of fixing the issue. (Side note, Fiocci dummies are NOT suitable for dry-fire as their cartridge head is just flat, no primer, and it bends if you dry fire). After studying the anatomy of the feeding system, I saw for myself that if the mag tube is properly installed all the way in, there were limited number of variables in play: 1) Friction inside the mag. 2) Friction from the receivers wall. 3) Friction from the rim engaging the carrier latch. It basically the carrier latch surface itself and the spring that pushes it outwards. 4) The power of the spring pushing the rounds out. So, before going into troubleshooting 1-3, I decided to order a couple of Carrier comp springs and try them out. I asked CC rep on the phone if they tried it with 5 round mag tube but was largely referred back to this focus, so I figured I'll need to experiment by myself... Once the springs arrived, I noticed that the springs are stiffer and LONGER that the OEM ones. The OEM ones when NEW are about 27'' long, after few hundred cycles, they shrink to about 25''. The carrier comp ones were about 31''. So, I installed CC spring and found that while it's longer, you can still fit 2 3/4 slugs into it, so it wasn't that big of a deal. After about two hundred of cycles of Fioccy dummies and rotating them to account for the rim wear, it was clear that the behavior has changed. Basically, I wasn't getting any mid mag TFTs anymore, the ones I was seeing with OEM springs, but was consistently getting 70% of FTFs on the very last round from the tube. It didn't make sense to me, so I re-installed the OEM one and it was back to "random" FTFs but no FTFs on last rounds. GOOD, I could clearly reproduce different failure modes with different springs. What didn't make sense to me was WHY the STRONGER AND LONGER spring was giving me such a high rate of FTFs on that last round. Anyway, I decided to see if reducing the friction will make things better. I replaced the carrier latch spring with a new OEM ones. It actually made things worse as that new spring needed some break it time likely, so I re-installed the old one. Then, I decided to give Dremel with some rough polishing compound a go and polish the carrier latch. After making the entire round rim facing surface slick and shiny, I immediately noticed an improvement. No, CC spring was giving me about 30% FTFs on that last round (down from 70%) and I could clearly see that on average, the rounds would get pushed further away from the follower and into the carrier. OK, it was great but still not enough. I did understand that slow and manual cycling wasn't the same as firing live due to no inertia that could help to push the round further into the carrier However, the fact that CC spring had these reducible FTFs on the last round didn't sit well... I came up with the idea that the bent shape of the spring in the mag tube may have a bigger impact on consistency and applied back pressure, which I was committed to test. Knowing that I could easily measure the impact by looking how far from the follower the last rounds get pushed, I decided to start chopping it in. The springs in 5 mag round M4s are exactly the same as in 7 round mag tubes. I made rather simplistic, and potentially flawed, assumption that I should be safe to go up to about 18'' inch length by using the "post break-in" OEM spring length of 25''/7 (size of the mag it was designed was) * 5 (size of the mag tube I have). Because it was easier to reproduce the issue on CC spring, I decided to use it and apply and start cutting 2-3 inch of length at a time. The end result was unexpected, the more I trimmed the spring, the farther away from the follower that last round was going. Once I got to 20'', the round was making it it to the retaining notch 50% at the far back of the carrier 50% of the time and was always at a solid distance from the follower. WOW. After manually cycling the dummies about 100 times, I saw 0 FTFs. Then, I installed NEW Carrier comp spring, untrimmed, and it was back to about 30% FTFs I had after polishing and before trimming. So, the experiment was clear to me, I switch to 20'' Carrier comp and went to try it out with the same mix of previously problematic live ammunition and saw 0 FTFs after 100+ rounds, half of which were cycled by only loading one round into the mag. I suspect, the OEM spring will exhibit similar behavior but had no time to experiment with it too. All in all, I learned a lot about the M4, the way in functions and can probably disassemble it with my eyes closed and replace the carrier latch / spring in minutes lol. Thank you for all the hints given in this thread and hope the information above helps somebody else.

-

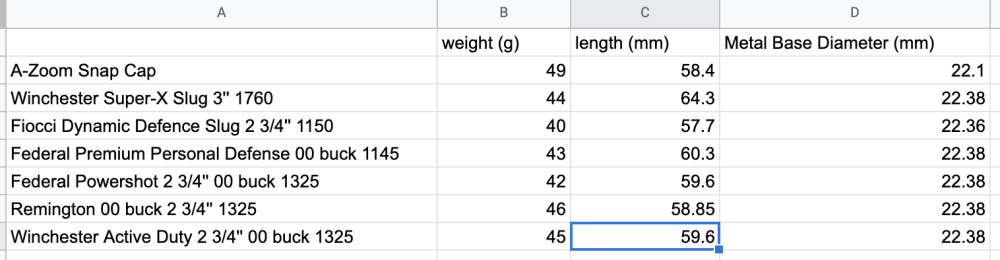

The A-Zoom snap cap are actually heavier than every variety of ammo I have. I measured and weighed what I currently have on-hand. See the screenshot. Granted, I currently don't have a place to shoot buckshot, I only tried the slugs from that list and some other slugs I had earlier. You can actually see how the snap caps metal base diameter is now smaller than live rounds as the M4 cycling kept grinding it. Yeah, I don't mind buying and trying it but It's 5 round tube that already won't fit 5 of the longer 2 3/4'' rounds in it as it takes the same 7 round OEM spring.

-

Interim update on it... 1) I couldn't reproduce this feeding issue with A-Zoom snap caps. They cycle with no issues. 2) I inspected BCG and upper receiver grooves for signs of irregular wear and couldn't find anything concerning. There are some spots on edge where black finish came off but nothing that would visible show any change in shape or anything. All-in-all, it doesn't appear that BCG has much to do with feeding issues. 3) I got two replacement OEM springs. While they looked similar but weren't quite the same. Replacements springs are 1 inch longer, have mate finish and appear a bit stronger. So, I replaced the sprint that came with the gun. 4) I went through about 100 rounds of four different ammo types and got one FTF, which is a marked improvement over 4-5 I saw before. Considering the about, it does look like replaced spring made it better but didn't fully resolve the issue. Upon further analysis, I can to conclusion that the ammo load doesn't have much to do with these FTFs but manufacturer is what's most common between rounds that have issues and the ones that don't. Any Winchester load appear to work fine with 0 FTFs, Federal, Fiocci and Stars and Stripes have issues. Changing the spring made Fiocci rounds cycle reliably, Starts and Stripes had that 1 FTF. It looks like some manufacturers have wider tolerances for round's metal base width, that's why some round have more friction going from the magazine to the far edge of the carrier and end up not fully engaging carrier latch. The carrier latch itself appear to have rather stiff spring. I attached a picture of the wear on the receiver from cycling the shell and the wear on snap caps. Basically, it appears that rounds going out of the magazine face rather still resistance from the carrier latch that pushes them hard against the receiver wall (wear pattern is shown on the picture). You can also see aluminum scrap from grinding the edges of the snap caps. While I can't reproduce FTF with A-Zoom's, I ordered Fiocci dummies as these are cheap and have more feeding issues as per the Internet anecdotes. At this point, I'm going to check if I can polish the carrier latch and the receiver wall a bit. I also have a spare carrier latch spring I may consider replacing to see if the new one is softer. Frankly, I'm not a mechanical engineer or a gun smith or even a power user of shotguns, so if the analysis above appear to be critically flawed, please let me know.

-

Thanks. I'm getting new OEM springs delivered today and do some suggested experiments. My POV is that a high quality shotgun should "just work" majority of the time, with no 3rd party mods. So, polishing the tube and using after market springs is a bit of an anti-pattern for me, I appreciate all the info shared though.

-

Thank you for suggestions. I didn't notice a definitive pattern, it's definitely not every last round but it's also not every first out of the mag... Anyway, I just ordered a couple of OEM m4 springs, easy to try it out.

-

Stock, 5 round mag, fixed stock. Model: 11795

-

Hi, I recently got an M4 that now has about 200 rounds on it, cleaned it a few times already. The problem is that with some ammo, I see FTF 5%-10% of the time. Lighter slugs / buckshots (1150 FPS), some (1450 FPS) slugs. Had no issues with 1500+ FPS slugs. When it happens, the round gets to the carrier but the bolt gets locked in the rear. Pushing bolt release button or racking the charging handle chambers the round with no issues and it fires fine after that. Any ideas are appreciated. Thank you.