Jeff in CO

Members-

Posts

8 -

Joined

-

Last visited

-

Days Won

1

Jeff in CO last won the day on March 1 2020

Jeff in CO had the most liked content!

Recent Profile Visitors

The recent visitors block is disabled and is not being shown to other users.

Jeff in CO's Achievements

Junior Member (1/3)

5

Reputation

-

Jimbo, Thanks for the info on the choke. I think it was the Benelli rep at that was working with my agency that had stated that, but I have never seen it in writing. I guess the choke still has me baffled as to why they have always included the modified. When shooting buckshot with the FliteControl wad or Hornady's version, it opens up the patterns with mine. We had anyone going through the transition course switch it out with the cylinder choke just to tighten up those patterns. You're probably right about the lower round count. We ran the M4 transition course (from the 870) over 3-days with approximately 500 rounds. It just guaranteed for a duty weapon that the kinks and problems would be worked out. Have a great day!

-

The M4 is similar to an AR: heavy lube the bolt assembly, and moderately lube the trigger assembly. Don't do the pistons or the cylinders. Don't dump lube down the firing pin. If you are ever shooting and start experiencing problems, spray some CLP into the bolt through the ejection port. You can do this with an AR as well. I typically always have BreakFree CLP in my range bag for this very purpose.

-

"High brass" these days is a little bit of a misnomer. There are plenty of high velocity and magnum rounds that use low brass, and vice versa. As for the M4, I've had one for years and even used it on patrol. When I first got it, there would be an occasional misfeed with low recoil buckshot (in the 1,100 FPS range). After a few hundred rounds, I have since never experienced those issues. The rounds I use consistently for tactical work (and defense) are the Federal LE132 00 (9-pellet low recoil, 1,145 FPS with FliteControl) and the Federal LEB127 LRS (low recoil TruBall slug; 1,300 FPS). I also shoot full power loads, all the way up to the Brenneke "Special Forces Maximum Barrier Penetration Magnum (1,650 FPS with 3,545 Ft-Lbs. of energy, yes, you really feel that thing!!!). If yours breaks in and doesn't have issue with low recoil, go for it. Low recoil loads allow for very quick follow-up shots for both defense and competition. With the assisted gas piston system of the M4, I think it is less finicky than the M1/M2 systems would probably be. I don't know why some people say things like they did with you, other than not having one and being a "know-it-all." The best advice, try a whole bunch of different loads and determine the reliability. After you have run around 500 rounds through it, go back and re-run another series of loads that may have had issues initially. Every shotgun is different, and what works for mine may have issues in yours. Also, for whatever reason, Benelli felt the need to include a modified choke with the M4 (both the LE and civilian versions). I've never understood that logic. They don't recommend running slugs through anything tighter than an improved cylinder. I personally keep a cylinder bore choke in there since I typically run the FliteControl buck loads. They don't need a constricted choke and actually open up more with tighter chokes. By switching out to a cylinder bore or an improved cylinder, it also allows you to go back and forth between good buck loads and slugs. IMHO, the M4 is still one of the best tactical/duty shotguns on the market. At the same time, the tactical shotgun is something to train with and master. Learn to master it, and it won't let you down. Enjoy your new tool! Jeff

-

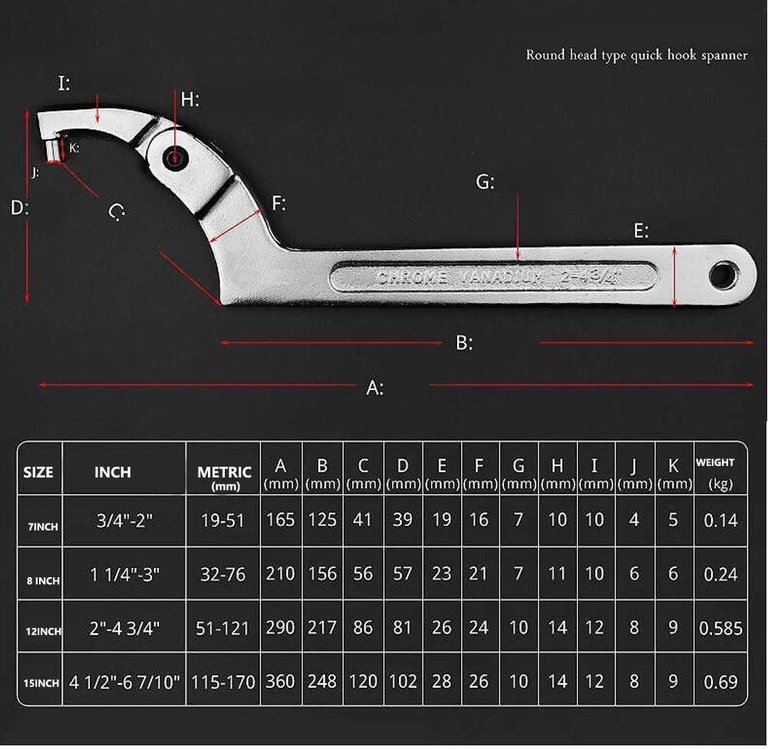

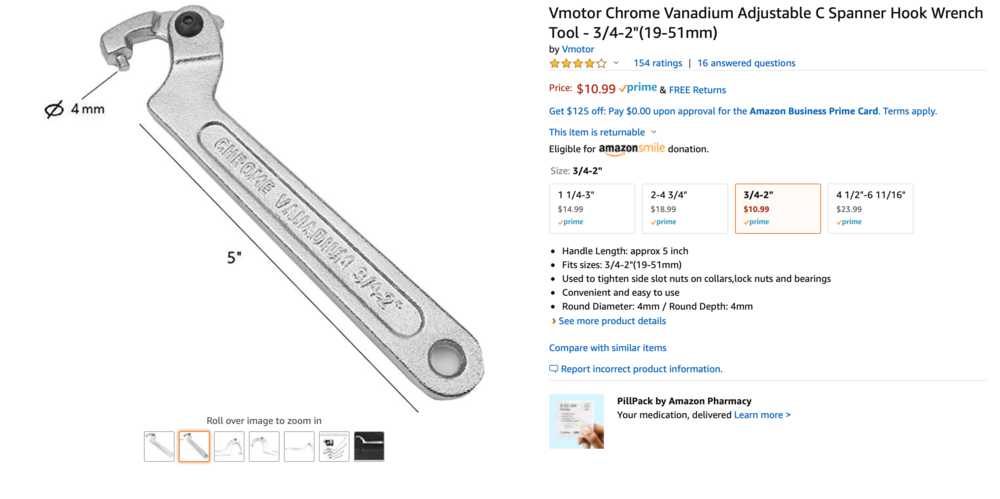

PROBLEM SOLVED!!! ? Schutzhund, Thanks for the reply! You would know better than I would. I was quickly perusing the M3 manual and probably missed it. As far as I know, it is the same stock system, but I cannot remove mine like they show with the M3 (from the top as that extra "U"-shaped cutout is not on my grip). I think part of my problem is the factory had the retaining nut torqued down so much, it was going to be impossible to move it with something like the bolt. I went ahead and purchased the "Vmotor Chrome Vanadium Adjustable C Spanner Hook Wrench Tool - 3/4-2"(19-51mm)" from Amazon (link in previous post). The holes are 4mm in diameter, so the other wrenches on that page would be too big (correct size highlighted in screenshot with pricing). It's only $11. I'm guessing they use something similar to this in the factory. It loosened the nut with virtually no effort. The surface is wide enough, it doesn't mar the polymer top of the grip (although I'm sure over time I will start to see a little shine from it, but that is no big deal). It also allowed me to easily torque the grip back on so it won't loosen while shooting. I'll just keep this in my gun case with the gun. Hopefully this helps if anyone else runs into this. I still think Benelli needs to do a better job with providing information about this, especially on the pump SuperNova that doesn't have any sort of charging handle. Jeff

-

Thanks so much!

-

What's the RTV mod? I have the Hayle rail on mine and like it but also really hate those stupid screws for field stripping it. Was looking at the new Truckee from Mesa Tactical (8-½" version), but I like the contour of the Hayle better since my Surefire pressure pad is high on the rail for my thumb. Attached is mine (for the record, it does have the benelliparts.net 922r trigger, hammer, & disconnector, plus of course the Hayle rail - it is an original LE model that I used on patrol, but I figured as soon as I swapped the stock, I should do the compliance parts as well).

-

Schutzhund, Thanks for the reply! I looked at the M3 instructions to see what you were talking about, and the M3 doesn't require that nut to be loosened to remove the trigger group. On the M3, there is an additional U-shaped notch (on top) where you insert the bolt handle to remove the stock (see attached photos from Benelli's website). That's not the part I'm talking about. I'm talking about that locking nut that is only accessible from the sides. The holes are only about ¼" deep, and I did try a screwdriver (partially bent it) and it won't budge. I also tried the charging handle bolt from my M4 shotgun (I believe it is identical to the M3's), and it is just a little too large to fit in the holes. Underneath the holes is the threaded shaft, and the idea of messing up the threads would be a disaster. I'm looking at trying this: https://www.amazon.com/dp/B076PL3VFJ/ref=psdc_553408_t1_B000RHSNQE?th=1 and placing a towel over the top of the grip. It would really be good to know what others do, as well as what Benelli actually uses, since they require it for a field strip. So far, I'm a little frustrated with Benelli's lack of information/response on this. Had the shotgun now for 2-months and cannot use it since I cannot even field strip it. I have a hard time believing that other people have just marred up their pistol grip stock field stripping this thing. The nut from the factory is really torqued down (note bent Milwaukee screwdriver above) and won't even remotely budge.

-

Hi, I'm shamefully new to the Benelli forums. After owning various Benelli's and even using an M4 on patrol, I just never signed up here. Anyway, I recently purchased a new SuperNova Tactical LE model (20159) which utilizes the telescoping stock. The manual states for Trigger Assembly Group removal (Page 59 in the 01/2017 version): "When the pistol grip or telescopic stock is installed on the shotgun the stock must be loosened before the trigger guard assembly can be removed from the receiver. To do this partially unscrew the pistol grip stock retaining nut or the telescopic grip retaining ring nut; thus making it possible to detach the pistol grip stock or the telescopic stock grip front the receiver to provide the space necessary for removing the trigger guard assembly." What tool do you use to remove this nut??? I have searched all over the internet and YouTube. Over the last two months, I've sent repeated messages to Benelli (using their online submission form) and never got a response. I called customer service this past week, and they told me to use either a crescent wrench or pliers. I'm having a hard time believing that Benelli loosens and tightens this nut using a crescent wrench or pliers (plus it doesn't make good contact). I don't want to mar the pistol grip loosening this thing. It has holes in it as if there is some sort of special spanner wrench to loosen and torque the nut. Does anyone know what tool Benelli really uses and the proper way to loosen this thing since it is required for a general field strip? I saw this question posted on here back in 2010 or 2011, and they never got a response. Thanks in advance for any advice that can be given! Jeff