Dkay67

-

Posts

167 -

Joined

-

Last visited

-

Days Won

8

Posts posted by Dkay67

-

-

-

Looks like the foregrip will allow better light placement to eliminate barrel shadow and expand options for pressure pad/modlite pad placement, cleaner wire routing etc.

-

2

2

-

-

Mlok and enlarged release button, nice

-

1

1

-

-

This is totally the fault of the buyer to fail to fully inspect the shotgun.

After the forms are filled out and the transfer made - its yours, and if you failed to inspect it, then its on you for not exercising proper due diligence

-

1

1

-

1

1

-

-

Pic of this grail handle?

-

1

1

-

-

1 hour ago, brightt said:

I see the benefits of what your saying, the ease of slapping on more rounds (quicker and easier to discard and remove weight, good point)

if I am carrying extra shell cards not on the gun, that means I have something I am carrying that is holding those extra cards!

I gotta debate between this and the shell cards, I want the option for another tube of reloads on the shotgun! A 3rd reload with an extra shell card is appealing.

my concern is attachment method of the shell cards especially on a brand new 11711 np3 benelli

Thing is, with the hard mount, you've got to have a pouch to store the loose extra rounds. That's extra movements - which is crucial time. Imagine doing a load from a bag for each round, or as many as you can hold and manipulate under pressure in a reload situation.

Another nice thing about the esstac type solutions, is that they will fit in standard AR magazine pouches so you could have one staged on a battle belt, or on a light plate carrier. A pouch of loose shells will just swing, make noise, and could be in the way, or even out of reach when you want to keep eyes on target

Slap one esstac on for a ready to go 6-7 rounds, or manually load 6 or 7 each to the hard points. IMO better efficiency with the esstac. But thats just me

As for the attachment method? Clean the surface of the gun with alcohol prep pad or similar, trim the velcro to fit, including the trigger housing pin to access, and attach the velcro. It stays put. Wont mar the finish of the shotgun, even the cerakote titanium ones.

And if the velcro goes bad, easy peel and reinstall with a new pad.

Hope that's helpful

-

1

1

-

-

It looks okay, but it definitely isn't a scalarworks killer.

The limitations of the shell carrier vis a vis other options such as the Esstac shell cards. The hard point carrier needs to be reloaded per round/shell, and then unloaded...several steps imho that are unnecessary.

The esstac cards can preloaded and then removed or slapped on as necessary.

Jmho.

-

1

1

-

-

53 minutes ago, RxArms said:

Man, that is amazing prices. They screwed the world with covid lockdowns disrupting the flow of the earths economy, not sure it will ever come back to a nice balance any time soon.

Ain't seen nothing yet.

-

3

3

-

2

2

-

-

16 hours ago, VoidEngine said:

Man, I'm a new owner of an M4 and I overlooked the price of accessories before getting it. I just couldn't pass it up for 1400. However, I am having a hard time justifying spending 800 more for it to meet 922r and have a C-stock. Any helpful suggestions?

Haha... now try Knights Armament for sticker shock

-

1

1

-

3

3

-

-

2 hours ago, RxArms said:

Shameless plug… I’d like to throw my offering into the ring, it keeps the weight of the handle at the OEM weight, 12g, while giving a much bigger handle for operating. Ti handle and stainless steel tang to prevent wear from the detent. (https://rxarms.com/product/benelli-m4-titanium-steel-tactical-charging-handle/)

the TTI handle weighs 28 grams, although I do admit they have a nice design, at the sacrifice of weight. The GG&G 3/4” steel weighs around the same.

this year I’ll be offering my design in 4140 hardened steel also. Estimated to be around 17-18 grams, and same locking design (which is similar to TTI locking). Probably in June 2022 I will have stock

Can you take a pic or two of this installed charging handle on the M4 to give a sense of scale/ proportion?

-

12 hours ago, brightt said:

$160 shipped

You might want to try ebay as well. Fishing with Many hooks better than just 1

-

1

1

-

-

-

Might be helpful to include your website link.

-

1

1

-

1

1

-

-

1 hour ago, CobraBG said:

I would agree that the battery location on the RMR seems to be a concern. I run 3 RMRs on different weapons and I just replace the batteries annually. It really has not been an issue. Replacing the batteries is still very simple.

Agreed, it's not really a big deal.

-

1

1

-

-

44 minutes ago, Kahamu said:

Speak of the devil.. scored a P2 along with an 11.5 SR15 upper from the rooftopdefense drop last night. Where did you get the MOS plate for the acro from?

That KAC battery cap is nice but they are going for $150+. I don't think it's even worth the $40 it retails for. Ended up parting with mine.

Even worse than $150...

-

1 hour ago, brightt said:

wth does that mean? you just look at the website and hit refresh for months on end? hahaha

No. There are ways to automate the process.

-

1

1

-

-

1 hour ago, brightt said:

huh? I got a couple people subscribed there, never heard a thing.

You can't rely on email based alerts.

-

1

1

-

-

25 minutes ago, RxArms said:

sold out already... crazy times indeed. Maybe I should make some of these...

They lasted less than an hour after I posted this lead.

-

Very cheap 3 position

https://www.midwestgunworks.com/page/mgwi/prod/70043

Click that upvote button if you buy and save ? ✅

-

1

1

-

-

1 hour ago, KiloEcho6 said:

Anyone have pictures of a smaller case for SBS? The M4 Entry, collapsed is 30.5”.

Perhaps go to Lynx Defense and see whats available in that size? They do have different gun bags available with pictures and measurements

-

1

1

-

-

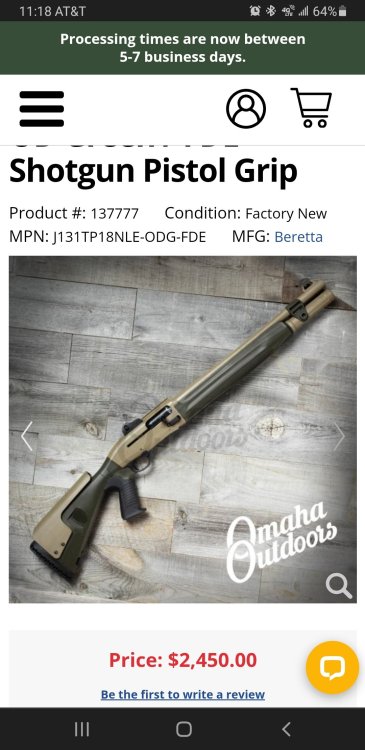

Live at omahaoutdoors.com

-

Still Available bump

Will consider reasonable offers

-

-

2 hours ago, StreetSweeper56 said:

I ordered one of these, got it today and it's very nice. It doesn't really look like a gun case which is what I wanted, very non-descript. I am going to put a couple LaCrosse patches on it as it's my new "racquet case", lol; hidden in plain sight! Made in the U.S.A. is a bonus as well.

Could you take some pics of this case in some closeups?

What kind of zippers does it use? YKK?

Are there storage pockets or velcro for attaching additional shell cards (esstac)?

Thanks

Np3 replacement announced

in Benelli

Posted

Appears to be same/similar chemical structure and have same/similar appearance and benefits.

From the email, couldn't attach jpegs for some reason

NT7™ & NT7 Plus™

The long awaited NP3 Replacement Coatings

In October of 2021, without any warning the NP3 family of coatings was discontinued from the retail market. We were just as shocked as you and we vowed that we would find a suitable replacement. Our goal was to find a coating that was similar in performance, chemical makeup, and corrosion resistance.

Over the past 2 years we have enlisted the help of the top chemical engineers, process engineers, and coating specialists from across the country to help us with this tall order. Through this process we discovered that we actually had two problems to solve.

First was the obvious, we needed a performance coating that could meet our strict requirements. Secondly, and just as important, we realized we also needed an applicator that we could trust to apply the coating.

We were unsuccessful on both fronts. After much deliberation we realized that there was really only one option.

The only way to get the coating performance we needed and to ensure that we could provide the service that our customers deserved would be if we designed our own proprietary coating and undertook the significant investment to build our own inhouse plating facility.

I am excited to tell you that this is exactly what we did.

Construction of our inhouse plating facility started in March of this year and barring any unforeseen construction delays will be completed by the end of August.

**Please DO NOT SEND IN COATING ORDERS until we announce that we are accepting orders**

We will be equipped to process: Steel, Stainless Steel, and Aluminum parts. We plan to be processing customer parts starting in September.

The replacement coatings NT7™ & NT7 Plus™ will have very similar performance specs to the NP3 specs and just like their predecessors the “Plus” coating will have a higher corrosion resistance.

NT7™ and NT7 Plus™ are based on a Nickel Teflon coating so they will have a similar satin Nickel appearance and the same low coefficient of friction and non-stick properties that we have all come to know and love over the years. We will be releasing pricing and more details about NT7™ as September approaches.

Key Info:

We look forward to better serving you and your firearm refinishing needs in the very near future!

Sincerely,

Brian Wright

President & CEO