-

Posts

140 -

Joined

-

Last visited

Posts posted by Scalarworks

-

-

The rail is the mount. Aimpoint t2 only. Maybe t1, but not 100% sure.

Unobtanium is correct; The rail is the mount. The Micro version is compatible with both the Aimpoint Micro T-2 and T-1 (also H-1 and H-2). It should also be compatible with all of the Micro clones out there (but we haven't tested them all).

We will be offering two bundles: One with the Aimpoint Micro T-2 and the other with the Trijicon RM06. Scroll to the bottom of this page for details on both: https://scalarworks.com/optic-bundles/

-

You're still hitting your deadline listed on your website...that's special in and of itself nowadays.

Thanks, but originally the RMR deadline was listed as Mid February. We update those deadlines on the website as soon as we have fresh information. Unfortunately in this industry it does often feel like 2 weeks late is pretty much 6 weeks early...

-

So the good news is that we'll have both RMR and Micro versions available at the same time. CNC machining of all components is complete.

The bad news is that laser marking and anodizing are super busy and we don't expect to have finished parts back until the end of the month.

-

Thanks for the answer!

It's a pity. I think such a modification would be in demand, Docter fully compatible with Burris FFII/FFIII sight.

It may be possible custom order?

Sorry, we're not a custom shop.

-

Hello, this rail fit for Docter Sight II?

Thanks!

No Sir. Trijicon RMR and Aimpoint Micro versions only for the foreseeable future.

-

That's exciting news! I sold my BOR/RMR in anticipation of the IOR release, but now I'm having trouble deciding if I want to go with the Micro or RMR version. I can see the advantages of each (as you pointed out above), so it may just come down to aesthetics. Can you post a picture of each from the side (profile view)?

At this point I think it would be best to just wait for the production rails and official promotional photos. Won't be long now.

-

IS end of feb for the T2 mounts as sure a thing as can be in this industry, or is it just a "we hope..." type deadline?

IOR/RMR production is in full swing. First production batch will be done this Friday and sent to anodizing. Programming for IOR/Micro is done, and it goes onto the same machine this Monday. Screws are finished and will be back from Black Nitrdiding next week and then sent to Nylok (they usually turn things around in a few days. Packaging is being finalized now.

February is looking pretty good barring anything unforeseen.

-

Thanks, everyone.

This is just the tip of the iceberg.

-

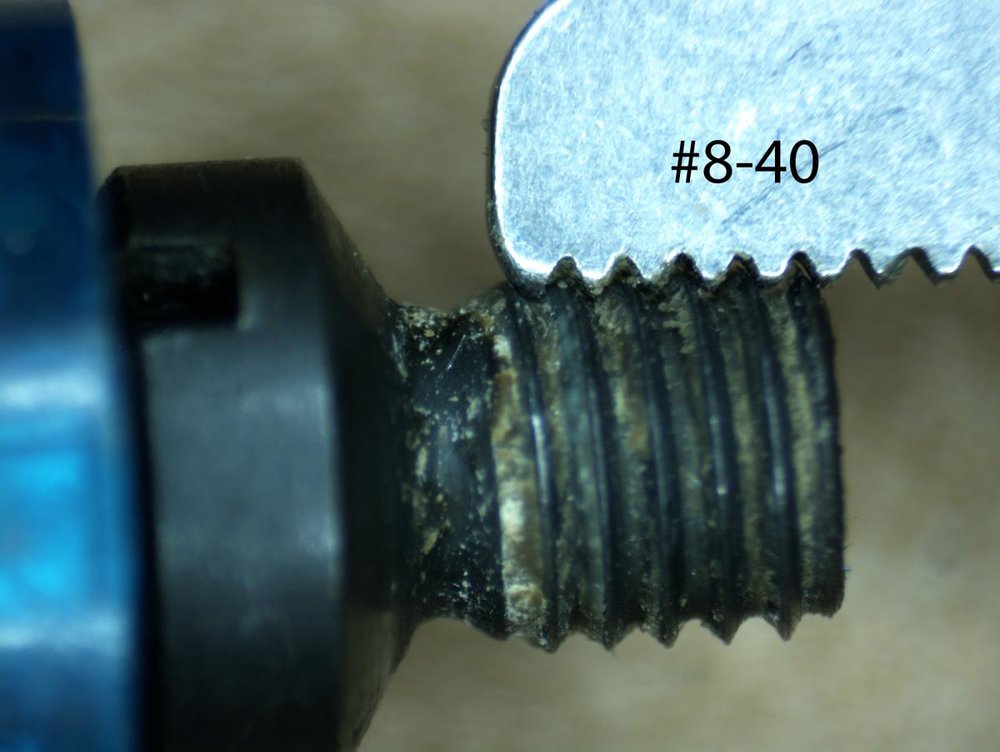

Speaking of IOR screws.

-

They are m4x.75. Not 8-40. The benelli is metric. Mesa did the same thing. Messed up a lot of guns. I'd urge you to verify this via very close inspection of an oem screw vs m4x.75 and vs 8-40...

http://forum.benelliusa.com/showthread.php/31943-Benelli-m4-rail-delete-screw-hole-plug-options

Benelli USA tech support has never impressed me with anything, from their spelling, to their erroneous information I've gotten numerous times from them. Just my experience, and I didn't talk to their lead guy, but I'm inclined to trust history, and 8-40 didn't work out so hot a few years ago. I doubt they changed the threads. I trust that you have both the ability and desire to confirm that m4x.75 or 8-40 is correct, and thank you for being diligent. Not a cheap mistake regarding a receiver.

Absolutely. This is by no means a cost savings the IORs will use our own precision CNC machined custom screws so we can make them literally anything we want with no difference in cost.

When we first launched the BOR100 over two years ago we used the stock m4 screws as they were convenient. When we set out to design a follow-up that would both place the RMR even lower, and make the rail compatible with every Benelli receiver that was drilled and tapped, we had to ditch the stock screws.

We read that forum post you referenced and started with M4x.75 screws. It certainly made sense at the time that an Italian gun maker would use metric screws. Unfortunately we found that every M4x.75 screw we tried showed resistance when screwing into a fresh receiver that had the thread thoroughly cleaned. This made us take a step back and re-assess. So we busted out our thread gauges (Mitutoyo 950-253 and 188-153), fired up the microscope, and tried comparing the stock m4 screws to both 40tpi and 0.75metric. See the results for yourself:

We then tried several types of #8-40 screws, and they all screwed right in with no unexpected resistance.

We followed this up by speaking to Carter Miller (Benelli USA's Technical Support Manager) at SHOT. We were told he's the most senior technician they have, he knows everything about every Benelli shotgun made, and he's been with the company forever (granted that doesn't mean he's right about everything, but lets give him the benefit of the doubt). He told us flat out that the screws were #8-40 (weaver standard).

With all of this, we were quite confident that we had the correct screws, and we launched the BOR110 shortly there after with four #8-40 screws. We've since then sold hundreds of BOR110's to people with every kind of Benelli receiver imaginable, from most, if not every, manufacturing year. We have yet to have a single customer call or email us complaining about cross threading.

In hindsight, the Picatinny rail on an m4 was not Benelli's idea, but the USMC's requirement. Back in '98 it's entirely reasonable to think that Benelli's engineering department would just adhere to the specifications for screws that were popular at the time, rather than trying to re-invent the wheel with unknown possible consequences. It's even possible the USMC gave them the specs for the screws. This is all speculation but entirely plausible. After the success of the m4 they likely just carried over the specs to their other shotguns. again, speculation but not unreasonable.

-

Don't believe everything you read on the internet.

#8-40 is what we measured, it's what we were told by Benelli USA's head of technical support at SHOT face-to-face, and it's what we've sold hundreds of with our previous BOR/RMR - all with zero customer complaints about cross threading since launch.

-

Excellent! Nylok patch included, I presume?

Yes sir. We will likely start listing both a Nylok and Loctite torque setting for all of our products starting with the IOR.

-

Another question somewhat related. I have developed an appreciation for your attention to detail as a company, but it still pays to ask.

Are the screws that interface with the receiver hitting as much thread-surface as the OEM screws? benelli uses an odd screw for this, or so MESA said when everyone stripped their receivers out...

So my question is, what torque spec is recommended? Do you recommend the re-use of the Benelli lock-washers? Have you measured threads to insure proper interface?

The screws are #8-40. This is historically what Weaver Rails (precursor to Picatinny rails) used with thin walled bolt action receivers. The extra fine thread pitch gives it more surface area to bite into.

Lock washers have been debunked by modern bolt science. What keeps your rail screws in place is liquid threadlocker and sufficient torque - unless you're using an ingenious mechanism to externally apply a radial load to the head of the screw like our Low Drag Mounts do (pat pend.

). The lock washers on their own hinder vibration loosening more than they help, so please do not use them with our products.

). The lock washers on their own hinder vibration loosening more than they help, so please do not use them with our products. Benelli's official stance is that they don't have a torque spec for the m4 screws. They have always told us the same thing: tighten until snug + a bit, with some blue loctite. We've measured that to be around 10in*lbs with their screws for the original BOR100, and up to 16in*lbs MAX with the off the shelf BOR110 screws we were using -though unless your torque screwdriver has world class precision at that torque range I'd proceed with caution and stay around 10-12in*lbs no matter what.

The IOR will have it's own custom made 4140HT screws that have a Black Nitride surface treatment. These will have a different K factor than either of the screws we've used before. We won't assess the final torque settings until we have actual finished production parts in hand a few weeks from now: we rarely trust prototypes for that sort of thing. The info will be clearly stated in the accompanying instruction sheet.

-

Well, I'll think about it for a while.

I think the T2 is a better solution, optically, and the weight difference really is only what, 2oz?

2.5oz #everyouncecounts

-

Which do you prefer for this platform? Is the rmr more "open" feeling, or...?

How can a father chose between his kids

But seriously, they both have their strengths and weaknesses.

The RMR is a much sleeker and lighter package and is available with a great intermediate dot size (3.25MOA) that can be set to auto-dim while still being manually adjustable (on the RM06).

The Micro offers a larger window, better glass, and insane battery life. It also provides a slightly fuller co-witness due to it's low design. However it's much taller, and heavier than the RMR.

It's up to you which things you value more in your shotgun setup.

-

Yes. The sights will appear higher in the red dot window.

They are both very usable co-witnesses. People loved shooting the BOR/RMR and that was just shy of a co-witness unless you zeroed your m4 @ 100yrds - which brings up the rear aperture. The IOR/RMR sits the RMR 40% lower than the BOR/RMR did.

-

I know what your picture shows, but...in person, which allows more full use of the irons, in person actually running the gun, the trijicon or t2? By how much of a factor?

The T-2 has a higher co-witness. The RMR (and all micro red dots for that matter) is hindered in this respect by the hump behind the window.

-

Quick question...the T2 mounts from UNDER the rail, correct? What about the RMR? It mounts from the TOP, right? As in, I could not remove the T2 without removing the rail, but I COULD remove the RMR without removing the rail, right?

That is correct. These are the limitations in the designs of both sights and are unavoidable without compromising the mounting height above the receiver.

Also, for anyone interested, we have put up our shop pages for IOR bundles: https://scalarworks.com/optic-bundles/

We already have plenty of Aimpoint Micro T-2 and Trijicon RM06 sights in stock so they will both be available when the IOR's are ready for sale.

-

-

-

If we somehow shoehorned both sight interfaces into a single design it would compromise the product significantly. Doing them separate is more expensive for everyone but you'll hopefully love the product instead of just being OK with it.

-

So, if I'm understanding this correctly, one mount will accommodate either the RMR or Aimpoint?

No, they are two separate versions: https://scalarworks.com/optic-mounts/

What I meant was one common rail mounting system that would allow us to design a version for the RMR and one for the Micro.

-

your micro red dot mount looks better than the midwest industries one. i may have to order one of these.

Thanks!We'll post some pics of the IOR/Micro mounted to a shotgun sometime this week.

-

Pics look great! Can you please elaborate on what you mean by "extreme lower-third co-witness that is 36% improved over the BOR/RMR"? Thanks.

Thanks!The BOR/RMR placed the RMR 4.15mm off the top of the receiver. The new IOR/RMR gets it down to 2.66mm (36% lower).One of the shortcomings of the BOR/RMR that we set out to remedy was that you could almost just barely see the top of the front sight post through the rear ring with an RMR installed. The IOR/RMR will get the RMR just that tiny bit lower to let you see a bit more of the iron sights. It doesn't seem like much, but it's a big improvement over the original.

As for the IOR/Micro; it has a very similar co-witness to the RMR because it doesn't have the rear hump of the RMR to look over, which balances out the fact that we had to make the Micro's platform a bit taller than the RMR's in order to accommodate the Aimpoint Micro T-2's front lens cap.

BENELLI OPTIC RAIL The decisive Trijicon RMR mount for the Benelli m4

in Benelli

Posted

Quick-updates: