I didn’t really like the factory charging handle due to how skinny it was and the amount of play it had rotating and slop the “buttstock to muzzle direction”. I decided I could try to make my own on my mini lathe.

First, I took measurements of all of the critical areas, or areas I thought were most important. On the first prototype, I discovered the most important measurement was the distance from the ball detent notch to the area where it tapered from .199” to .258”.

On the 1st prototype, I made the notch too far down the shaft, causing the handle to be easily pulled out and or twisted since the ball was barley in the notch. The 1st prototype was also made from 4340. Didn’t like the idea of having to blue it and keep it oiled to keep it from rusting. The 2nd prototype and my final product were both machined out of 1/2” bar h900 17-4. Machined surprisingly well on my mini lathe using micrograin carbine tooling and medium speeds. The 4340 was almost too gummy and soft, and was chipping edges of my tools, which is probably due to lack of machining experience. Had zero tools break or chip while using the 17-4. Since I was making my own, my main goal was to eliminate play, and make the handle between .400” and .500” in diameter.

The 2nd prototype was .500” in diameter and had zero play. Was machined from 17-4 as previously mentioned. My goal was to get a close match with the titanium cerakote by stone washing. (I literally used stones off of a dirt road and put them in a water bottle. Wrapped water bottle in socks, and had it go through the dryer’s tumble/no heat mode for about 8 hours. Came out looking really good, but didn’t match.) The handle was also heavier than I wanted it to be. I figured if the handle was too heavy it would cause feeding issues when using lighter loads. The main reason it was too heavy was because I only used a 5/16” drill, meaning there was about .094” of wall thickness. Way thicker than needed, especially while using such a strong steel. While this handle was heavier than the stock one by a decent margin, had no issues cycling what I’d consider medium target loads through my benelli m4, which only had around 50 rounds of buckshot through it at that point. With the 2nd prototype installed, I shot 50 fiochhi target loads, 30 Federal LE slugs, and 50 rounds of Winchester SuperX buckshot with 0 malfunctions which surprised me due to how heavy it was.

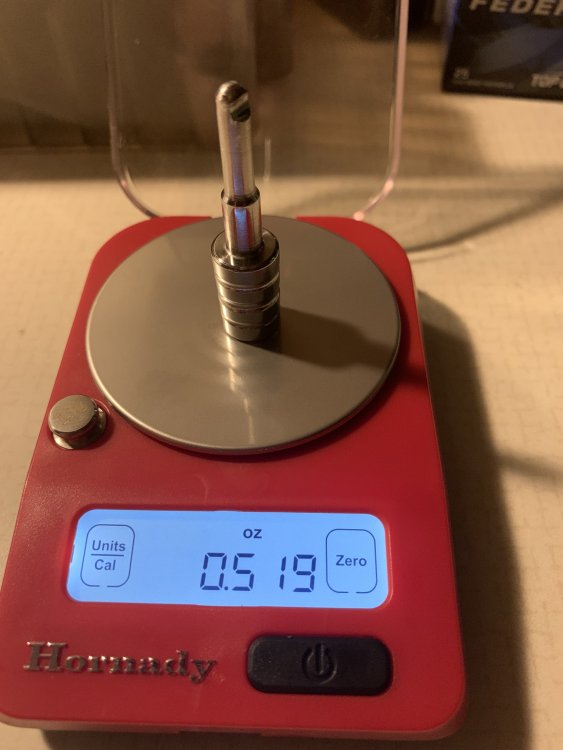

My final product weighed a good amount less due to the handle being around .450” in diameter and me using an 11/32” bit. This made wall thickness somewhere around .055”. Still more thick than necessary for what this is being used for. Since the stonewash didn’t have the effect I was looking for, I figured I’d give it a decent polish to match the TT lifter I have on my gun. I really like the look, and the polishing didn’t make it any more slick than the stonewash finish. I also rounded the end of the handle making insertion easier than previous designs. Also makes marring the finish on the barrel less likely when using the handle to disassemble the piston assembly.

As you can see by the pictures, I only put one notch on the charging handle. I don’t know why the factory one has three notches, but that is one of the things that causes the handle to have slop. Using only one notch made the handle really tight and have zero slop in any direction, while also still being easy enough to remove by twisting and pulling. I also made the smallest diameter part of the shaft +.002” compared to the factory .199”. This eliminated the “front to back slop” I mentioned. If anyone is interested in the measurements I used, send me a DM and I’ll send you a picture of my drawing I made of the factory handle and it’s measurements and my handle and it’s measurements.

Thanks for reading, Bryce