benelliwerkes

Members-

Posts

808 -

Joined

-

Last visited

-

Days Won

24

Everything posted by benelliwerkes

-

Adding a QD mount to a M4 Collapsible stock. How did you do it?

benelliwerkes replied to REZARF2's topic in Benelli

Years ago mounted a Mesa Tactical QD to the grip roll pin location. You need right side mount, flip it about. -

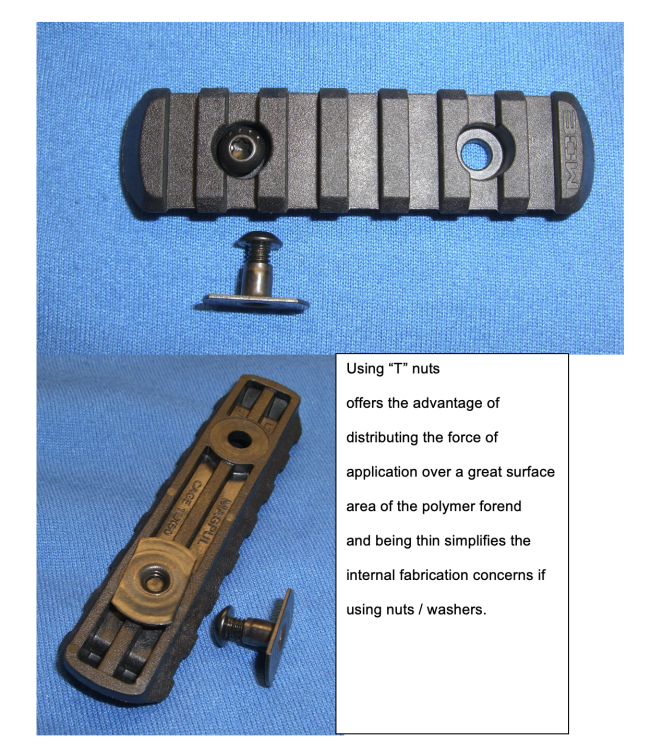

You can mount a rail to the OEM handguards....did it many years ago when the forum old guard were spitballing solutions. T-nuts work.

-

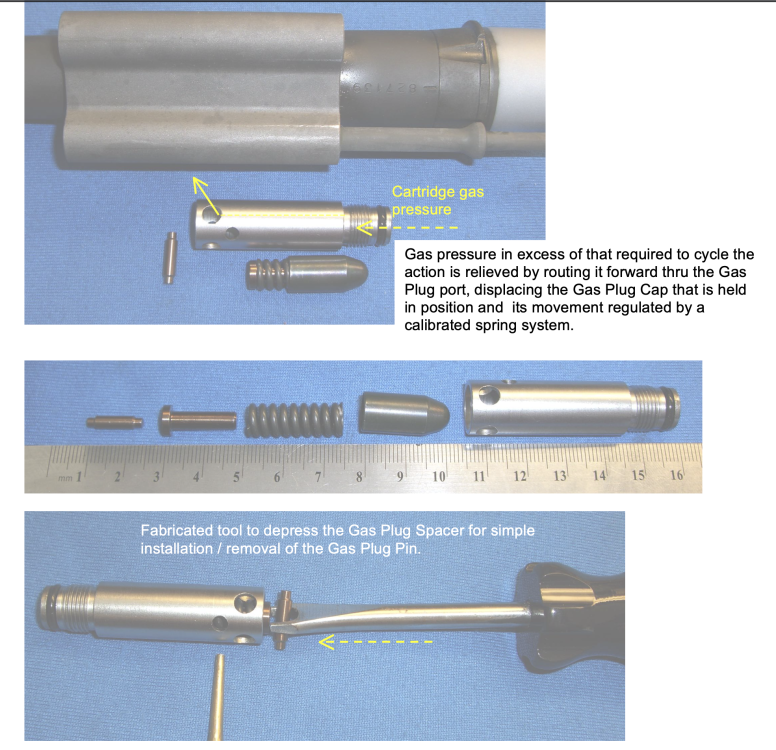

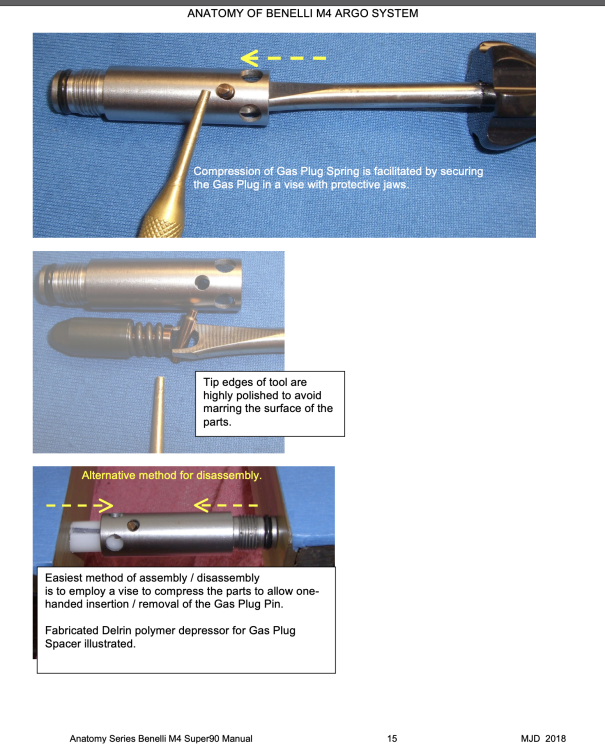

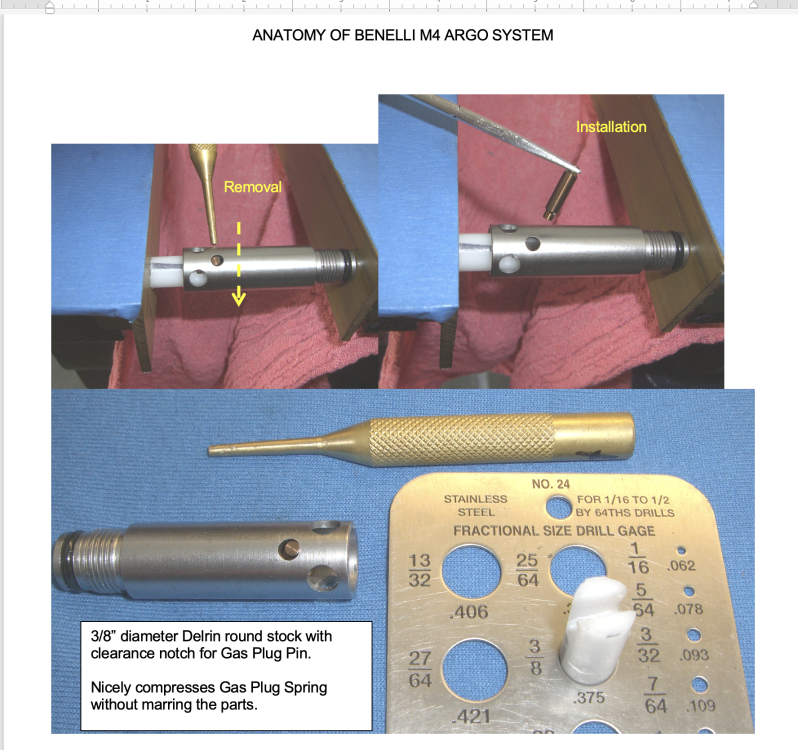

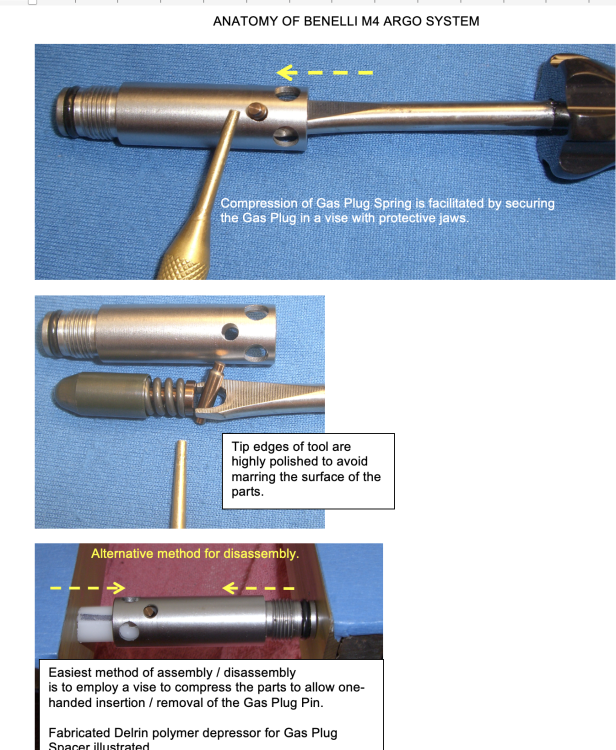

I posted this solution to the ARGO system years ago. Both a hand held tool and a Delrin slotted compression pin to release / install the ARGO pin secured in a vise. The factory tool is does not seem to be as kind as the Delrin and polished hand held tool.

-

Snooze ya looze. https://www.gunbroker.com/item/1025910100 https://www.gunbroker.com/item/1032179477

-

Gunbroker, one first appeared a few months ago, and this was the second one from the same large dealer.

-

Anyone have one ? Just sourced this factory t-tool; one end is 5.5 mm for front sight work, the other is for wrenching on the ARGO gas plug springs.

-

Well then, it's indeed handy to know your local laws! Did the thief drop the TV ?

-

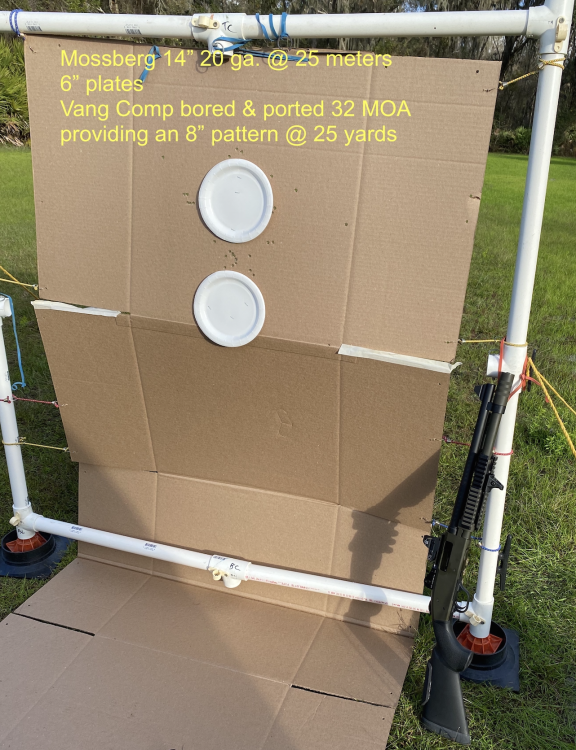

For home defense fully expect that you will be held accountable, both at civil and criminal law levels, for all 9-12 .30 caliber rounds contained in your 12 ga. "00" buckshot cartridge. One intended target miss and there they go down range thru the housing dry walls, a long way, into adjacent room spaces, your neighbors bedroom, etc. Unless the bad guy is charging into your home, and why would you be there with your loaded 12 ga. shotgun waiting to ambush him? Shooting the retreating bad guy in the back as he is retreating may be tempting at the moment, hope you can afford to defend the local zealot prosecutor on homicide charges. First off, you could throw a firecracker at most home-invading crackers, and they would scatter away like rats. Consider #4 or #6 shot shells for home defense, especially in 12 gauge; more than enough fire power to thwart a rat, and the individual shot will most likely not exit your domicile to harm other innocents. Can't imagine even the rationale for using a slug for home defense. Just as FBI studies have concluded a M4 in 5.56 is safer on interior encounters than their 9mm pistols for over-penetration. Here's a 18" Winchester 1200 pump ("world's fastest pat 2ump shotgun") training at the elite Rogers Shooting School, using # 6 shot, slamming down head plates at 25 yards......it's more than adequate for home defenses. "00" buckshot is used for final testing, to make the student has acquired proper recoil management. Just sayin'. https://www.dropbox.com/scl/fi/rcco1d1f5ery84ndnlkh9/Rogers-School-Shotgun-Shooting-Test-4-copy.mp4?rlkey=1f8hx8qd49qald62pvr1ojp17&dl=0

-

It's admirable to try and play nice with 922(R) guidelines. However, unless you are already in the line of night vision sight of criminal law enforcement prosecutors no one is going to check your firearm for minutiae compliance details against the "list" of items to be compliant. IF the lawman ever comes knocking to inspect and itemize your firearm accessory list you are in heap of deep legal ginsha. Be quiet, drop your dime to your lawyer and await his/her arrival. This would be a "add on" prosecutorial charge to have the long arm of the Feds to punish you further. Just for fun try to cite a single case in modern history where some poor soul was prosecuted on 922(R) during routine traffic stop, at the local gun range, selling their firearm online etc.

-

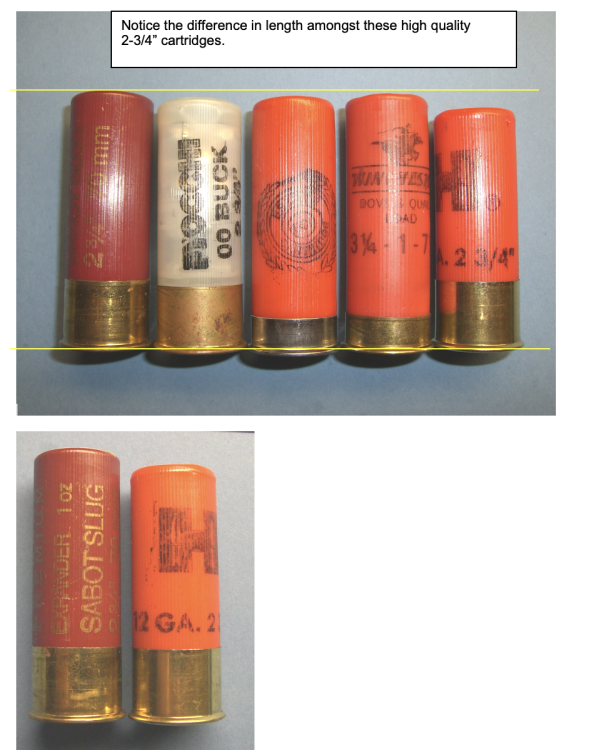

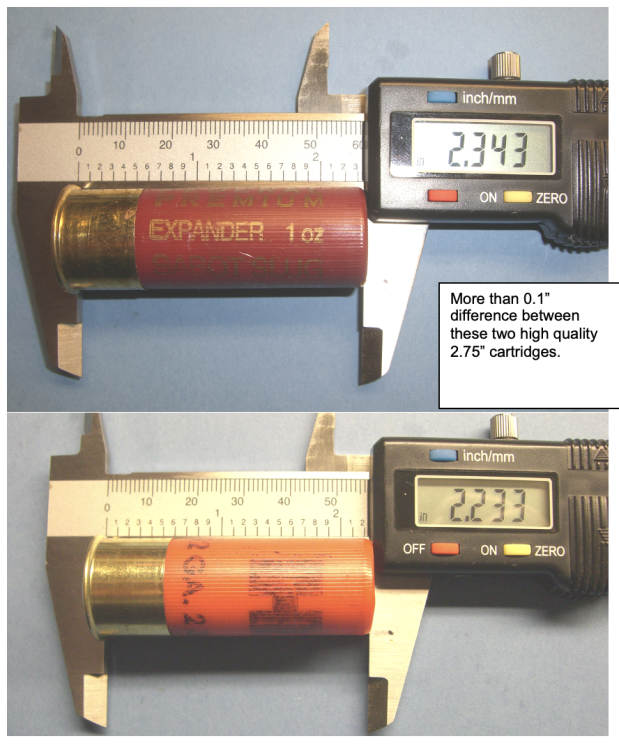

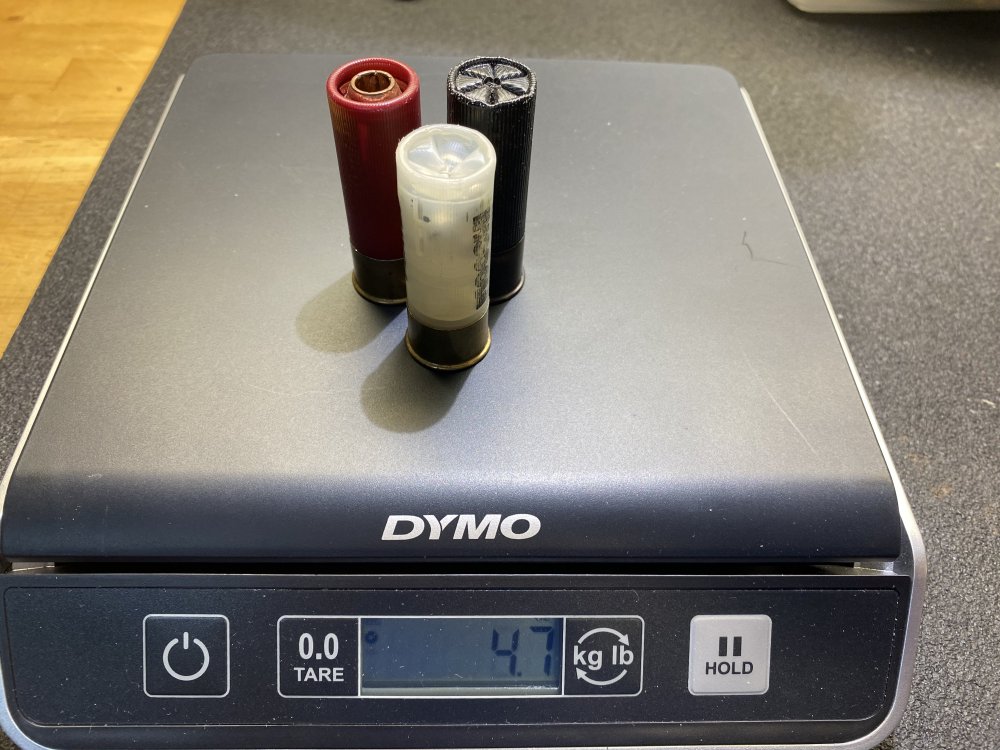

As mentioned above variations in the un-fired cartridge overall length can effect magazine load capacity difference and has been discussed for many years on this forum. The crimp on the un-fired cartridge is not relevant. The open crimp on the fired cartridge is relative to chamber length dimensions, i.e. 2-3/4" open shell should not exceed this length after being fired or extraction / ejection problems may arise. Comparing one firearm magazine capacity to another is apples & oranges.

-

Stranger will have the info you seek.

-

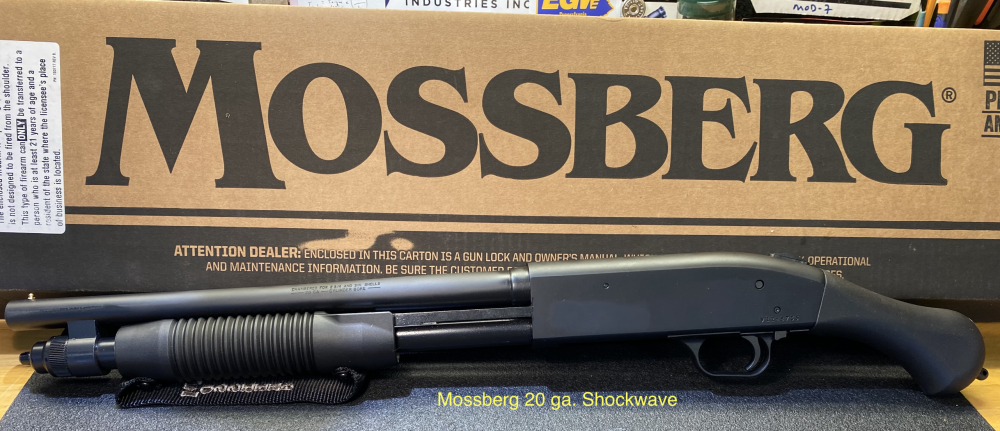

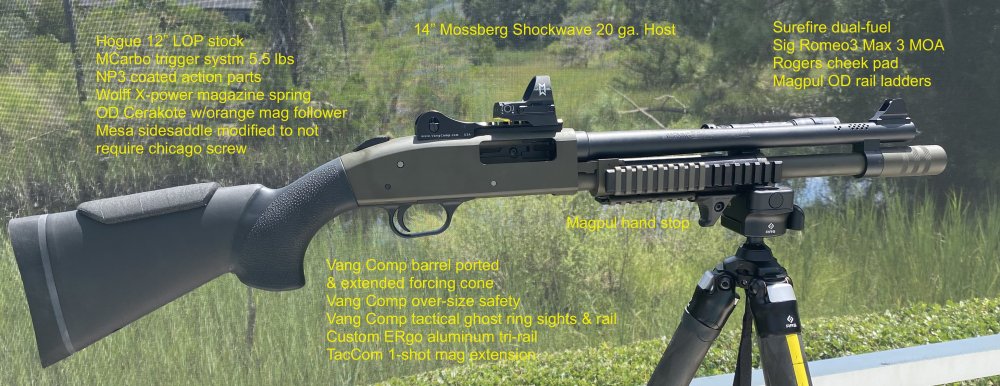

So, going the other way, Shockwave to short barrel shotgun, a Mossberg .410 and 20 ga. Less than 26" OAL, barrel < 18", intended to be shoulder fired. NFA "short barrel shotgun". These were submitted on a BATFE Form 1 ("mfg. a firearm"). That is, I manufactured this Short barrel shot gun, it was born a shotgun, no longer a fall thru the NFA cracks Shockwave configuration.

-

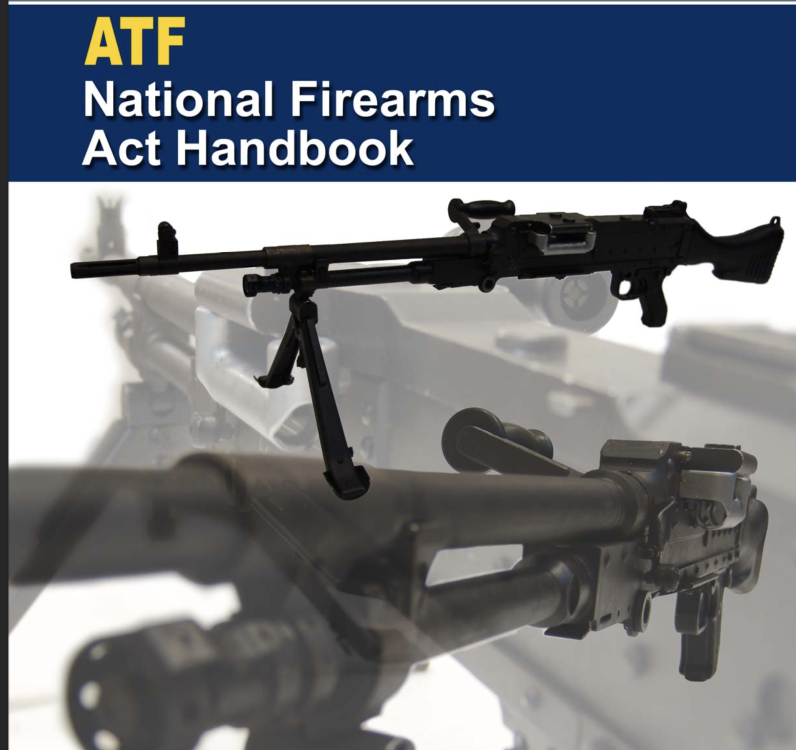

Negative, Ghost rider. Your depiction is that of weapon that appears to be less than 26" in OAL and a barrel of less than 18"; and not intended to be shoulder fired. It would never have been manufactured as a shotgun by definition, ergo, it never could be a "short barrel shotgun" in NFA parlance. IF less than 26" OAL with birds beak styled grip it would be NFA classified as an AOW, "any other weapon", requiring NFA registration with tax stamp etc. From the BATFE NFA Handbook: 2.1.1 Shotgun A shotgun is a firearm designed to be fired from the shoulder and designed to use the energy of the explosive in a fixed shotgun shell to fire through a smooth bore either a number of projectiles or a single projectile for each pull of the trigger.10 A shotgun subject to the NFA has a barrel or barrels of less than 18 inches in length. 2.1.2 Weapon made from a shotgun. A weapon made from a shotgun is a shotgun type weapon that has an overall length of less than 26 inches or a barrel or barrels of less than 18 inches in length. Featuring a 14-inch barrel, “birds head” pistol grip and an overall length of 26.37 inches, the Mossberg 590 Shockwave (and Remington TAC-14) does not fall under the purview of the National Firearms Act (NFA) and does not require additional paperwork or the payment of a tax stamp for transfers. The obvious technical design hurtles for the semi-auto depiction in such a small configuration with a birds beak have already been mentioned. My Remington 870 with 7" barrel was born as a registrable NFA "any other weapon", AOW; not a shotgun. Add a shoulder stock and it is still an AOW, as it was never born a shotgun, thus can never be a "short barrel shotgun".

-

Interesting piece. https://www.gunbroker.com/item/1025910087

-

-

Factory Benelli M4 Picatinny Multirail Handguard?!

benelliwerkes replied to ninjajim4's topic in Benelli

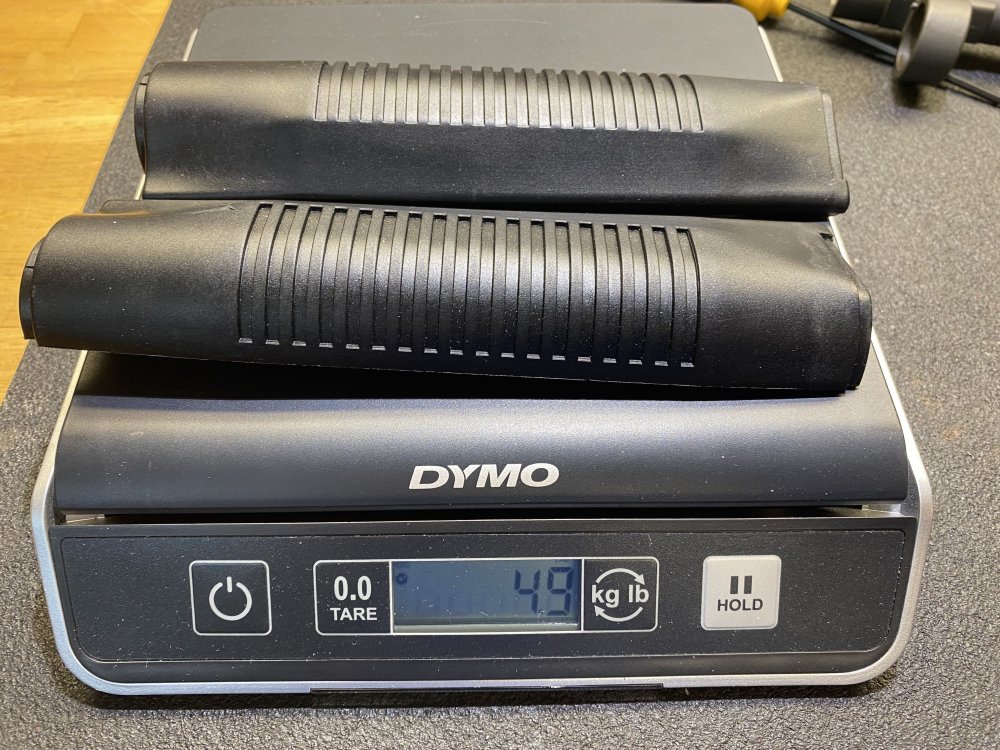

PSA- The Surefire M80 tri-rails only weighs 4 ounces more than the factory hand guards, that is less than 3 shotshells. The entire 14" M4 with rails weighs only 2 lbs more than 2 full size pistols. It has proven to be a very practical setup. Get some heavy cross-training shoes and don't be that Karen. -

Snap caps are fine. Use Lyman A- Zoom aluminum high quality 12 ga. Why ? store a snap cap in the chamber?

-

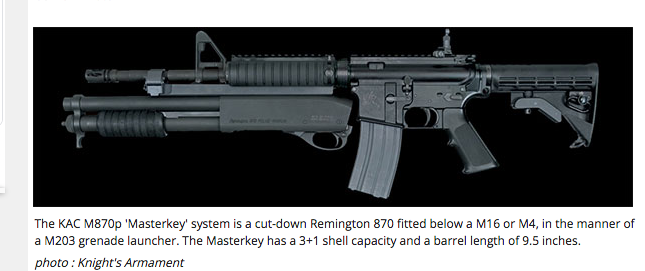

A few years ago just for fun I cobbled together some KAC MasterKey styled configurations. Noveske N4 SBR and 16" HK MR556A1 hosting a 7" Rem 870 3" magnum. The Mr. Obvious problem with these configurations are there are not sighting systems for the shotgun, ~ 4 inch offset from the carbine barrel, point shooting a 12 gauge load in close quarters when the shot collar has not even released yet!

-

Scalarworks has some nicely fabricated products.

-

As single individual seller, I would not list it as a penny start auction like the big boys do. List it with your "buy now" minimum and let the market take it where it will in the coming month......list it for 7 days at a time, if no sell, re-list adjusting the price or not the first two weeks as necessary; don't part out the accessories, the 2-piece diverter is the brass ring. The SPAS-12 market has been pretty strong for good looking gear like yours.

-

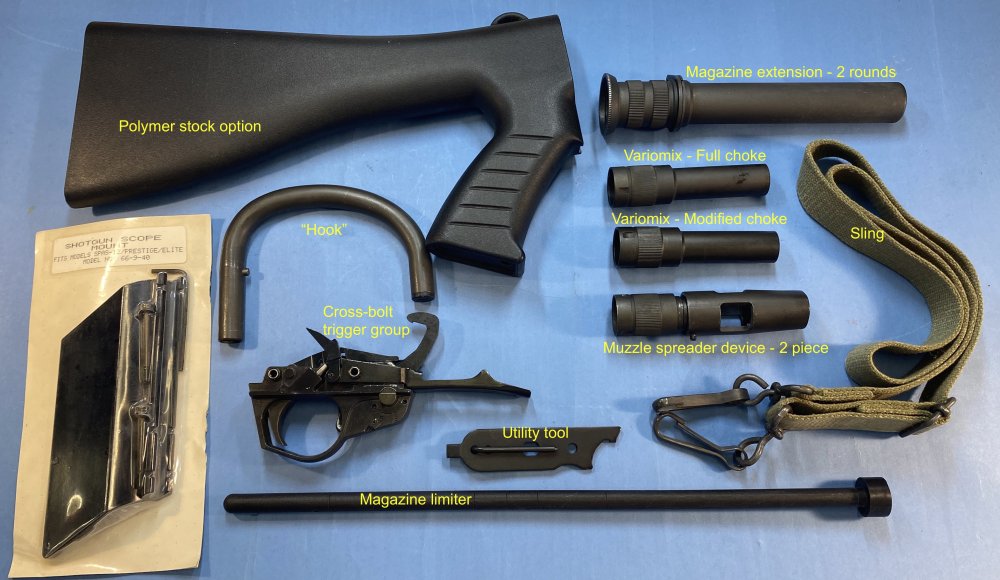

^^ Looks like all the desirable and now unobtainable nice looking accessories are present and accounted for in your assembly. Congrats & good luck! The 2-piece diverter is the most difficult acce$$ory to acquire.

-

The Weaver or Wheeler Fat Wrench would work well.

-

The follower is not the problem. An understanding of the various mfg. shotshell cartridge lengths is the karma. A 2-3/4" standard shot shell is the maximum opened length upon firing of the cartridge, i.e. the "petals" of the pleated end of the cartridge must not exceed 2-3/4" in order to be properly managed by a barrel chambered for 2-3/4" shotshells; same for 3" shells / barrel chambers. So when comparing various brands of 2-3/4" shotshells you will observe the unfired difference in their lengths, THIS is what collectively determines how many 2-3/4" cartridges can be inserted into a magazine of fixed length. A few 1/16" / 3-32" differential adds up when loading 4-5 cartridges, this is the governing factor as to whether one can load 4 of brand A v. 5 of brand B cartridges.

-

Factory Benelli M4 Picatinny Multirail Handguard?!

benelliwerkes replied to ninjajim4's topic in Benelli

I have used the aluminum Benelli M4 Surefire M80 quad-rail for years without any issues. How many more mounting positions does one need?