benelliwerkes

Members-

Posts

808 -

Joined

-

Last visited

-

Days Won

23

Everything posted by benelliwerkes

-

It was the implied sales pitch I was referencing not your employment history. Done here.

-

The non-starter for me is pedaling a non-Benelli firearm on a Benelli Forum and expecting hugs & kisses. No eye appeal for me. But then that's why there are 33 flavors of ice cream. I see a bulky forend bracket for the rail support. I see white letter highlighting for "Black Aces"......not seen on Knights, Benelli, HK etc.....; IF visually challenged naive friends Ask where can I buy one ?, that's your opening to disclose the mfg. The last time wood furniture seemed attractive on a tactical style shotgun was the Rem 870 standing upright in the middle of the bench seat of a Plymouth Belvedere, sometimes a AMC Matador, (with hemi interceptor engine) featured in the 1960's Jack Webb TV Series Adam-12. "One-Adam-12 respond"; what a great series it was. Officers in the day not afraid of offering a "wooden-shampoo" with their billy clubs to any misfits that needed to be cleaned up before getting to the Station for booking. The obvious style mismatch of corn-cob forend style with checkering for the stock wrist is a walk-away for me. Even looking at the depth of wood stain / wood figuring differences has me all cross-eyed. When one is in Sales, you need the thick skin to hear and gracefully accept the No Thanks.

-

I'll let the rest of the crew say what needs to be said out loud.

-

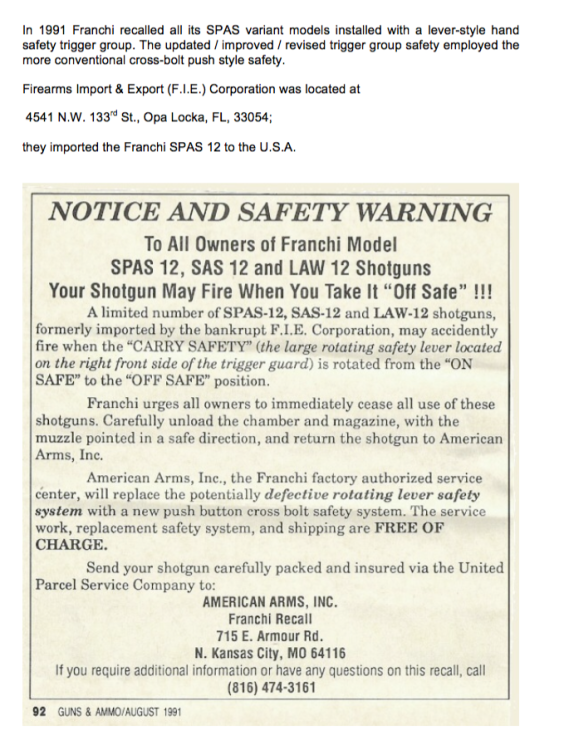

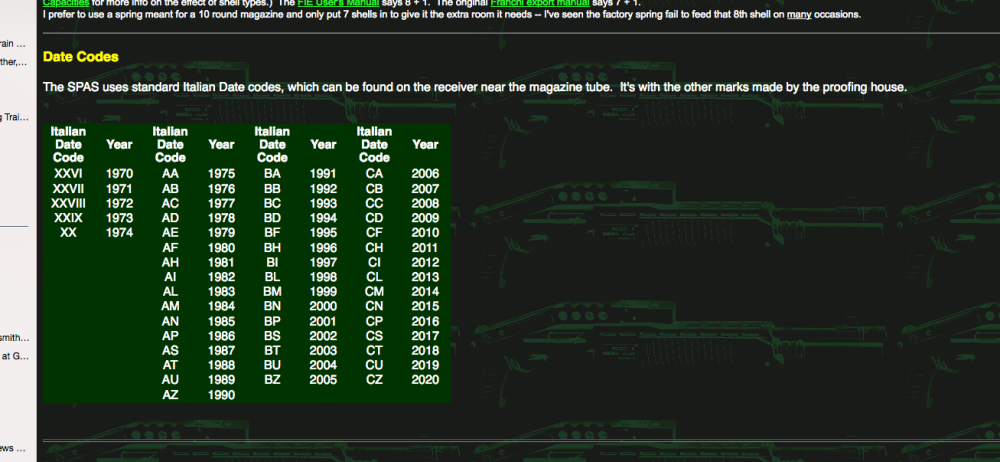

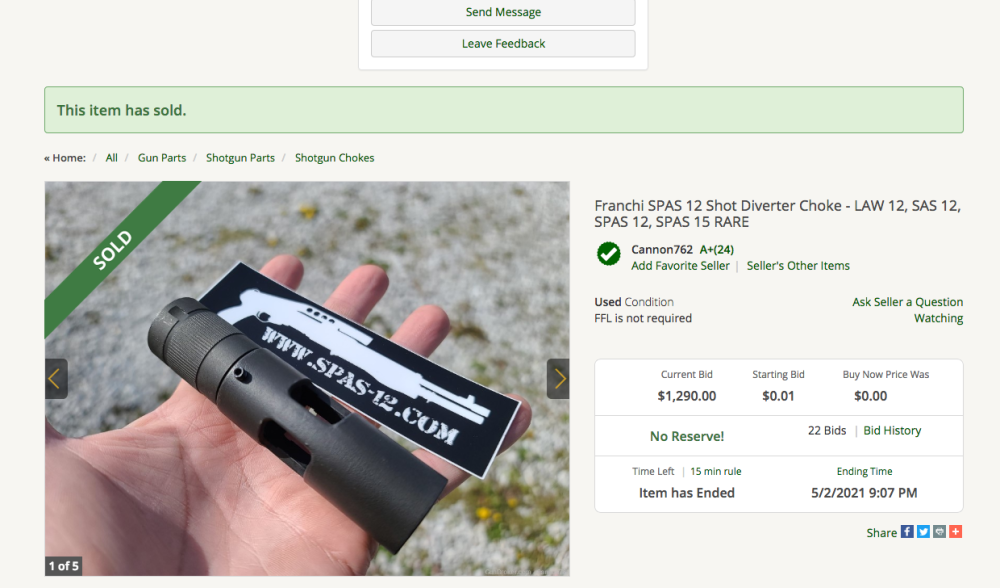

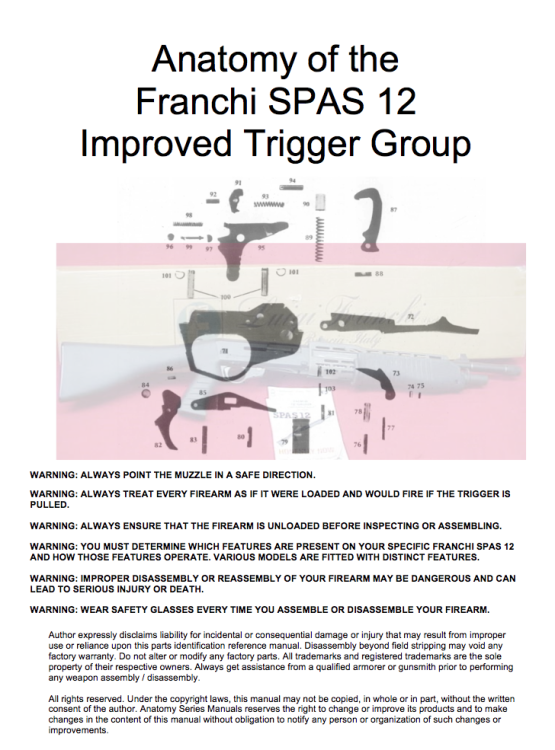

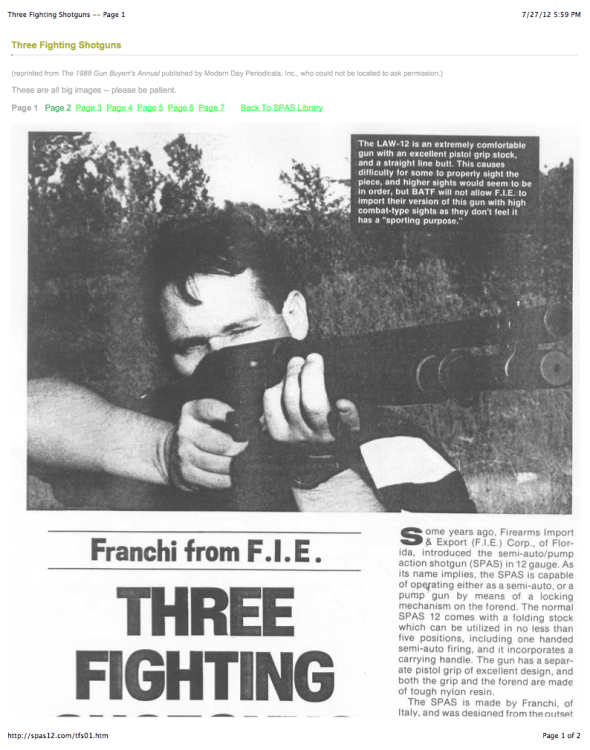

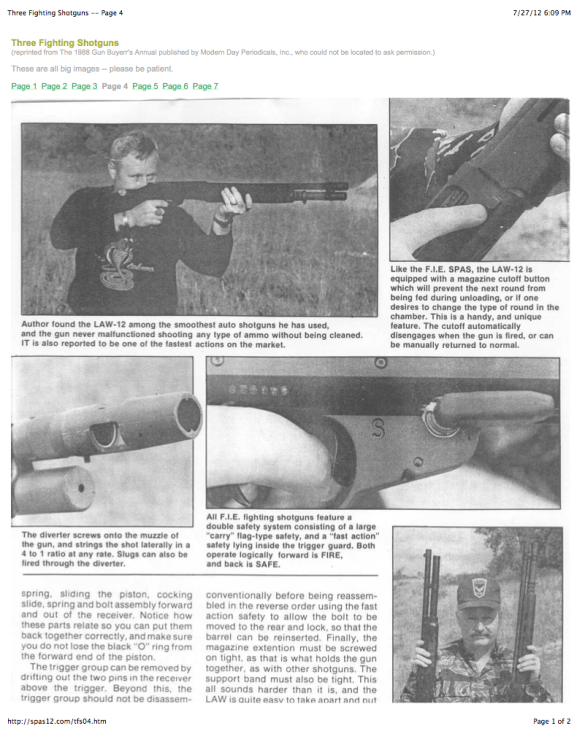

A friend actually gave me this 1983 mfg. imported via F.I.E. Miami, FL, NIB Franchi SPAS (Sporting Purpose Automatic Shotgun) with folding stock and infamous "hook" arm brace (way ahead of it's time) 10-12 years ago. It's definitely a cult firearm piece, glorified by it's highlights in Arnold Schwarzenagger "Terminator" movie. It took 10 years and $2500 for me to acquire all the known available "accessories", the last of which was the 2-piece muzzle "diverter" for $1300 in 2021, from the SPAS12.com site originator nonetheless. Several years ago I balked @ $500 for the device, bad non-purchase. It's one heavy and clumsy gun to manipulate. Importantly there was a Safety Recall in 1991 regarding the original "lever" style safety lever that would, without warning, discharge the firearm while toggling the lever from ON-OFF / OFF-ON position; a good time to emphasize the primary safety on any firearm is muzzle direction. My Franchi SPAS 12 (Sporting Purpose Automatic Shotgun) has a 21.5" barrel, SPAS 12 external muzzle thread protector, folding stock, 8 round magazine = pre-ban SERIAL NO. AL XXXX DATE CODE “AL”=1983 Imported by F.I.E. , Miami FL - collector desirable. pump / semi-auto modes. The pump mode was for cycling low powered rubber tip riot cartridges. First year mfg 1979. (1994 assault weapons ban) Removable magazine restriction plug, FIE scope mount, Vario-Mix choke tubes (cylinder, modified, full choke), sling, "hook", muzzle “diverter” device paid $1300 in 2021 for this 2-piece accessory Trigger guard “lever” safety (Safety Recalled in 1991; factory replaced recalls with the cross-bolt trigger group. SAFETY MALFUNCTION DEMONSTRATED: https://static.wixstatic.com/media/0cdaa4_952e6a62edc84135a0113b9964845d33~mv2.gif I authored an Anatomy Series Manual on the differences between the Lever / Cross Bolt safety trigger groups available that also details how the safety malfunction occurs and the factory resolution using the same lever trigger groups! A bit of musing on the "muzzle device" and it's parallel development in the armed forces follows. A variety of shotgun muzzle devices have been tried over the years to enhance their effectiveness in a defensive role. One item that comes off often is "Duck Bill Spreaders" most seem to originate in the early 70's. Crane Lake is often cited as were their origin and cited has being used by the SEAL's in Vietnam and by the Air Force Security Forces. In each case they are cited as being regulated for use with #4 buck shot. Relative reference manuals from the early 70's reveals #4 buckshot was the preferred load for LE-military shotguns. Crane Lake is often cited as such prototype muzzle devices used by the SEAL's in Vietnam and the Air Force Security Forces. A&W muzzle in "The Police Shotgun Manual", by Roger H. Robinson, 1973. Mr. Robinson includes many high speed photos that were provided by A&W Engineering of shot loads coming out of the A&W duck-bill device; photos show the diverter to be very efficient at pattern modification. At 10 yards a 7 1/2" H x 29" W pattern with #4 At 30 yards a 25" H x 96" W pattern with #4. A claimed a 22% reduction in recoil an diminish the muzzle flash to that of a .38 special at night. A slug can be used as well, imparting two grooves on either side of the slug with a reduction in projectile yaw. According to Swearengen in _The World's Fighting Shotguns, the US Air Force Directorate of Security Police in the mid-1960s developed a requirement for a spreader choke that would produce a wide elliptical shot pattern. This horizontal pattern spread was supposed to increase the hit probability from a shotgun on a moving target. The Air Force request went to Frankford Arsenal for action, at the time Frankford was working on improvements to the military shotgun in general. Early experiments at producing a spreader choke were less than successful- the chokes split, patterned poorly and in various ways failed to produce te desired result. Ultimately Frankford ordnance engineer Charles A Greenwood developed the duckbill choke in answer to the Air Force requirement. It was subjected to a good deal of laboratory and field testing. The original duckbill choke was simply a sleeve with a long V-notch cut on either side, the apex of the V toward the rear. The top and bottom of the sleeve were compressed toward the centerline at the muzzle, constricting the emerging pattern of shot in the vertical plane and forcing it to spread horizontally. The sleeve was permanently brazed onto the barrel so that it would not be blown off or rotated by firing the gun. Early examples of duckbill- equipped shotguns were deployed to Vietnam in the hands of Marines and Navy SEALs. It was found that the open V- notches in the muzzle of the duckbill hung up badly on vegetation as the shotgunner tried to move through thick growth, so the duckbill was modified with a ring around its muzzle to exclude vines and branches. It was discovered that the spreader device worked as advertised, but in reality what was needed in a fighting shotgun was a way of producing dense, lethal patterns. Spreaders in field testing produced patterns five feet high and twelve feet wide at 30 meters with #4 buckshot loads. At 40 meters, patterns were six feet high and sixteen feet wide. At 40 meters an average sized man would only be hit by a couple of pellets. But with a standard cylinder bored barrel shooting approximately a four- foot circular pattern at 40 meters, some 60% of the shot would strike an average man- sized target. Still, the duckbill choke had its adherents, among SEALS especially. Development on the idea continued for several years. Clifford Ashbrook and Wilson Wing of Kexplore, Inc. in Houston, TX developed the A&W Diverter in the late 1960s using mathematical concepts, and received patent protection (# 3,492,750) in February 1970. The HK 512 gas operated 7+1 shotgun, it was manufactured by Franchi for HK under a contract to supply an elite force in Germany (GSG9), i.e. the "Anti-Terrorist Shotgun" . A production over run of 270 units which were imported into the US, employing a shot diverter that creates a rectangular spread .

-

Alternatives to a side saddle for extra ammo?

benelliwerkes replied to SnidelyWhiplash's topic in Benelli

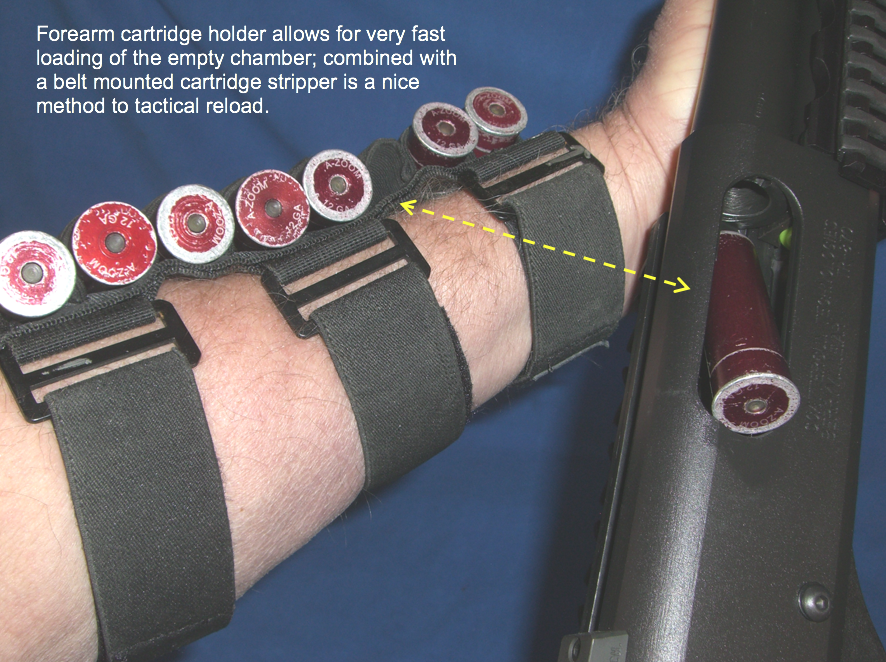

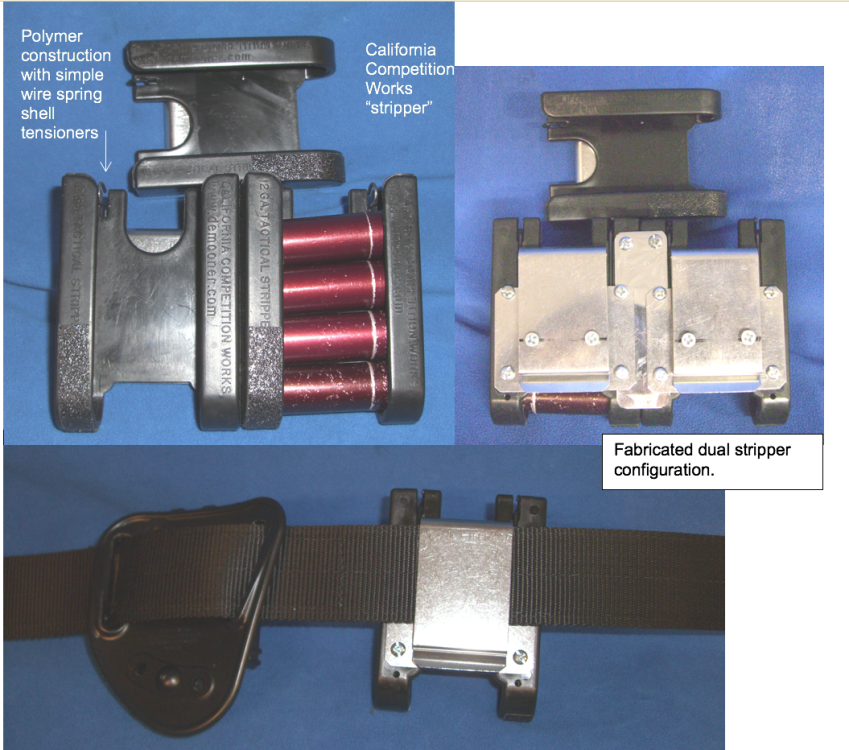

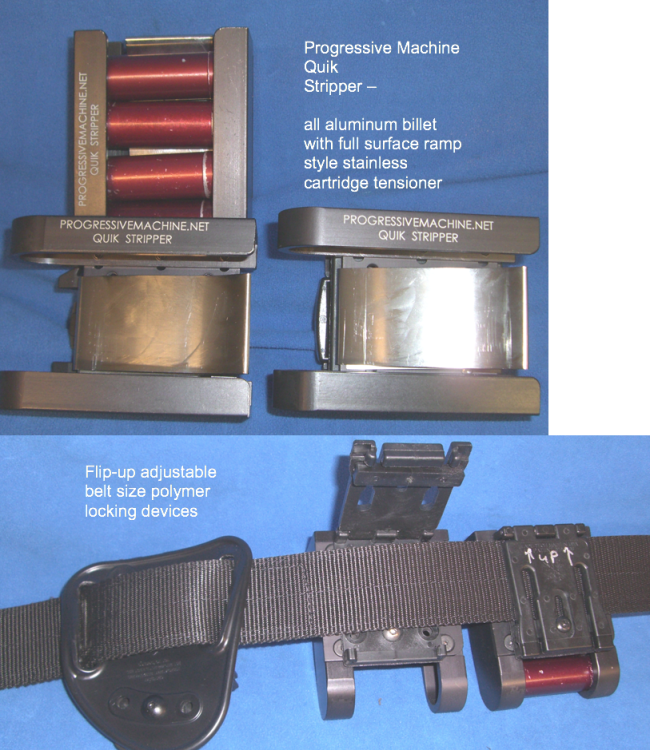

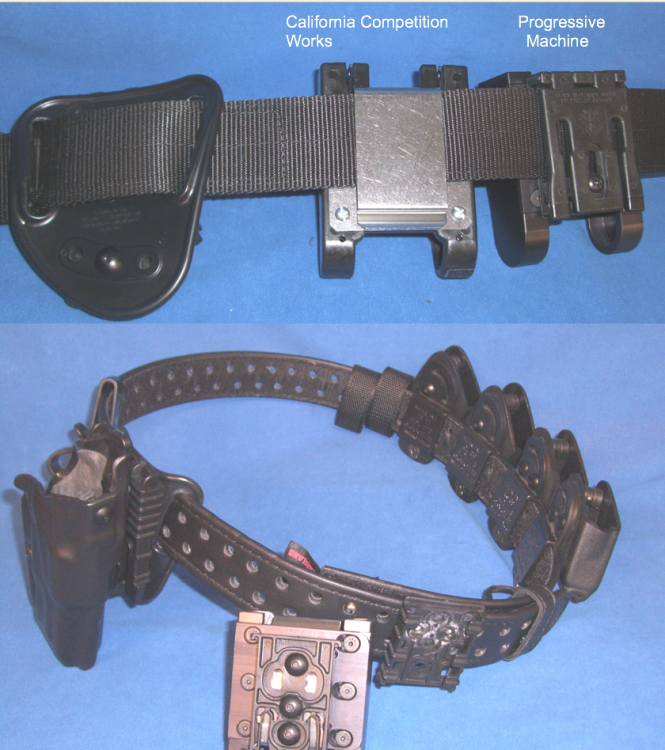

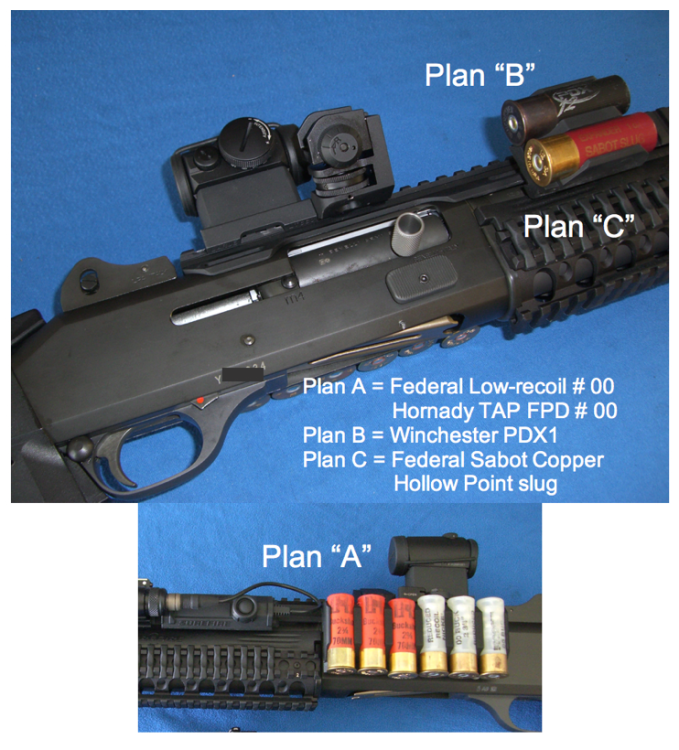

Moribund thread, but what the heck. The problem with shotguns for SD is the obvious limited round capacity and the need to understand if you are not shooting you better be loading. I have found for single breech loading, the Blackhawk forearm situation is really fast; supplement with grab-a-few shotshell carriers; the aluminum ones are far superior to the polymer style for functioning. The polymer shotshell holders are used as the standard at the elite Rogers Shooting School for their combat shotgun course of fire using the Winchester 1300 pump as the "school gun"; IF you can shoot the pump fast, you can scream an auto-loader. The 1300 and it's modern clones FN Police Shotgun have been described as the worlds fastest pump shotgun's with a rotating bolt; the recoil will eject the round if you take the support hand off the forend. https://www.dropbox.com/s/g7fbv3ywppxvpsn/Rogers Shotgun Test 4 Also copy.mov?dl=0 -

-

-

Best Benelli M4 Weapon Light Setup 2022 [New Stuff]

benelliwerkes replied to atlantixyl's topic in Benelli

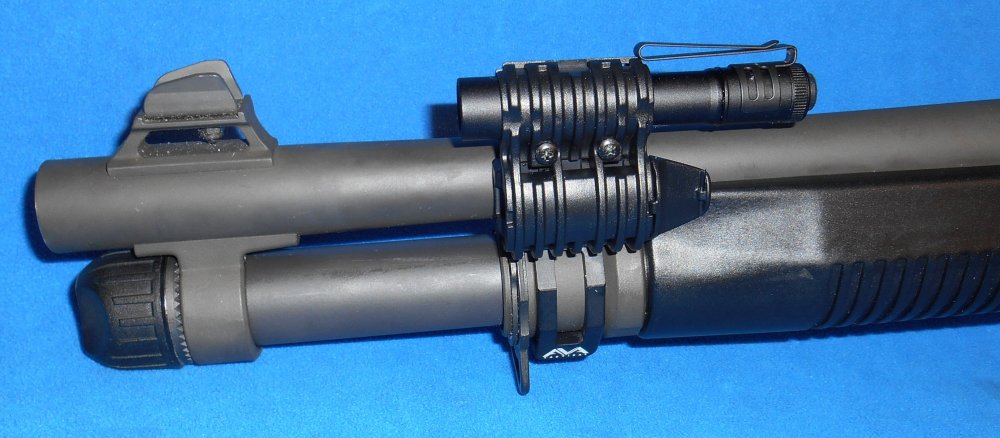

Don't like the 1.5" offset from the barrel. Their have been a number of good setups in the past, AVA tactical mount being one of them. Pretty easy to mount a picatinny rail to a factory rail panel as well. That said I like a SureFire forend tri-rail. -

Sometimes it's hard to watch the drama.

-

-

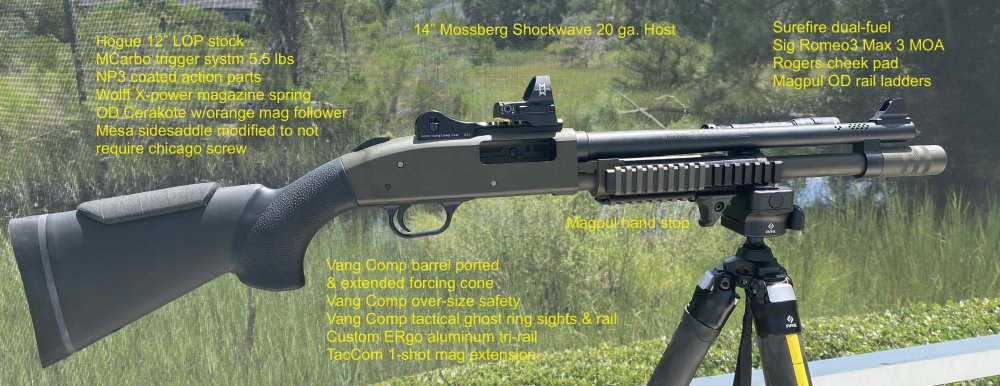

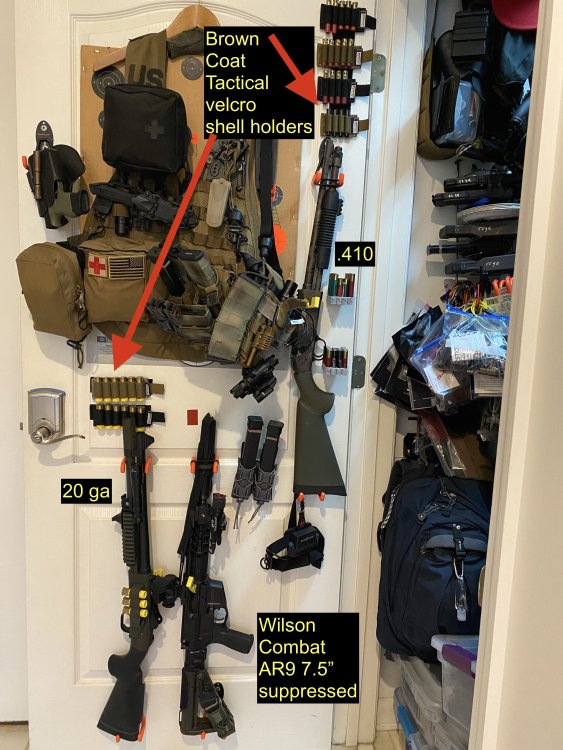

NP3 is getting increasingly more limited in retail sourcing outlets. I recently cobbled together these 14" SBS Mossberg Shockwave's, .410 & 20 gauge with NP3 coating of all the action parts. The .410 was done by Robar (no longer doing NP3) and the 20 ga. sourced by Vang Comp while they were extending the forcing cone / porting the barrel last year. Keep them handy in one of my load-out rooms for varmints and 2-legged malcontents. There is no aluminum tri-rail option for the .410 mossberg so for fun I fabricated a 6061 aluminum bushing on the lathe to mate the Mossberg .410 to the 20/12 gauge tri rail forend tubes.

-

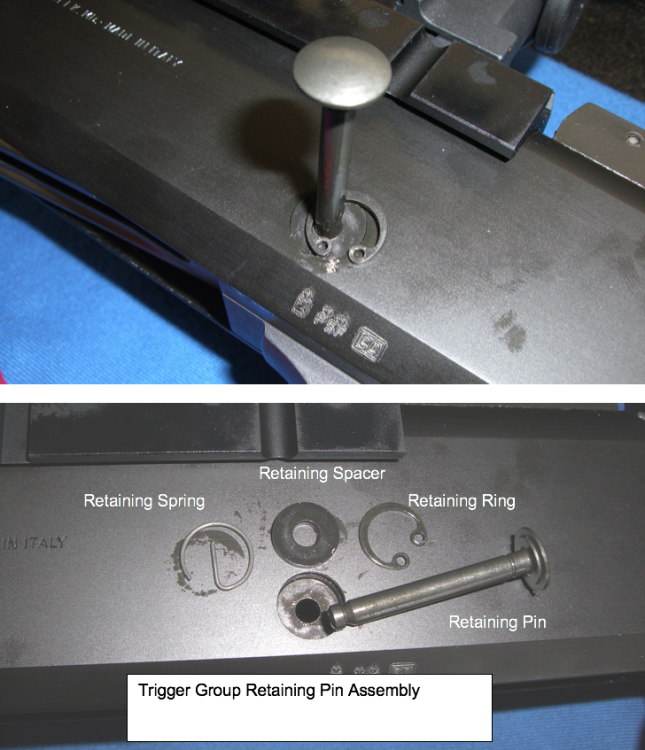

Looking for: BENELLI M4 SAFETY PLUNGER RETAINING PIN

benelliwerkes replied to 4eyedandshakey's topic in Benelli

-

-

Trigger Guard Pin coming slightly loose on a Benelli M4. Normal?

benelliwerkes replied to cfrea's topic in Benelli

-

No battery life boost. But, ANY important optic or battery powered gear (flashlights, range finders, lasers etc) use lithium batteries as one day you will open up your device and find a $1.00 run-away-alkaline energizer has chemically destroyed a $5000 schmidt & bender battery compartment. Don't be battery cheap.

-

The Double Gun Journal is what you follow for this passion. Great articles on the provenance of legacy gunsmith mfg.s.

-

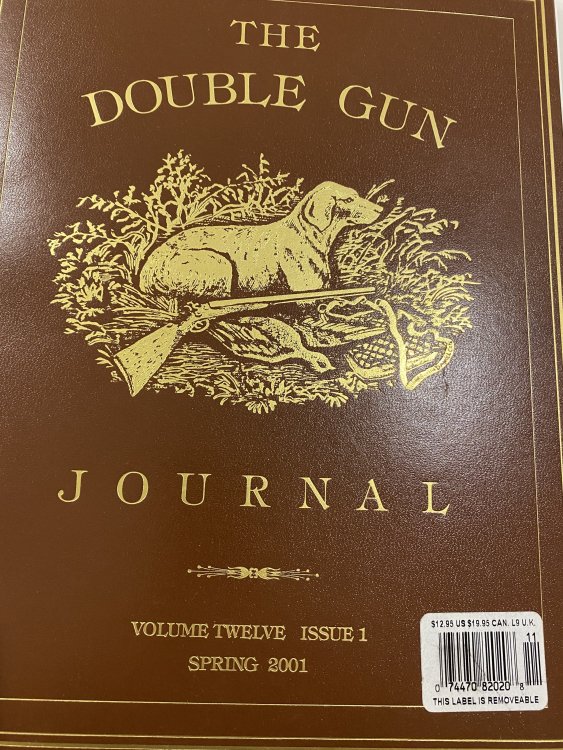

Any copper jacketed rifled slugs good in the M4?

benelliwerkes replied to Milspec's topic in Benelli

-

Any copper jacketed rifled slugs good in the M4?

benelliwerkes replied to Milspec's topic in Benelli

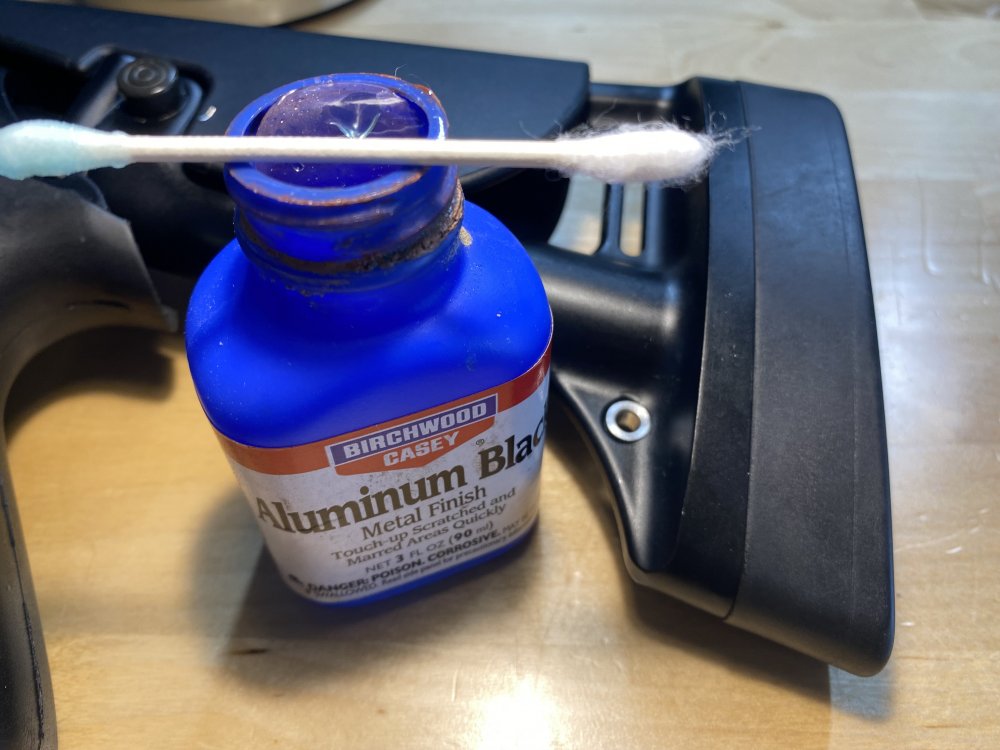

yes. keeps it from marring the receiver. -

Any copper jacketed rifled slugs good in the M4?

benelliwerkes replied to Milspec's topic in Benelli

-

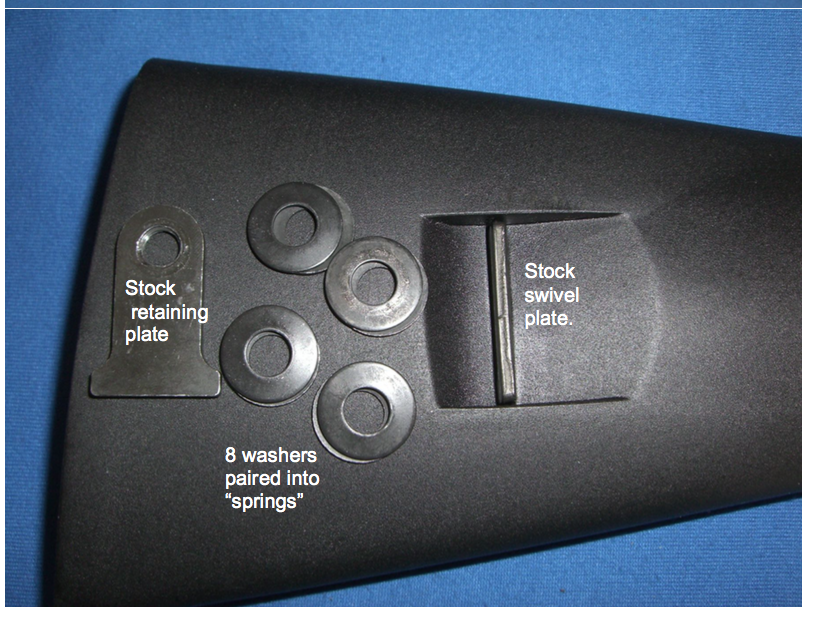

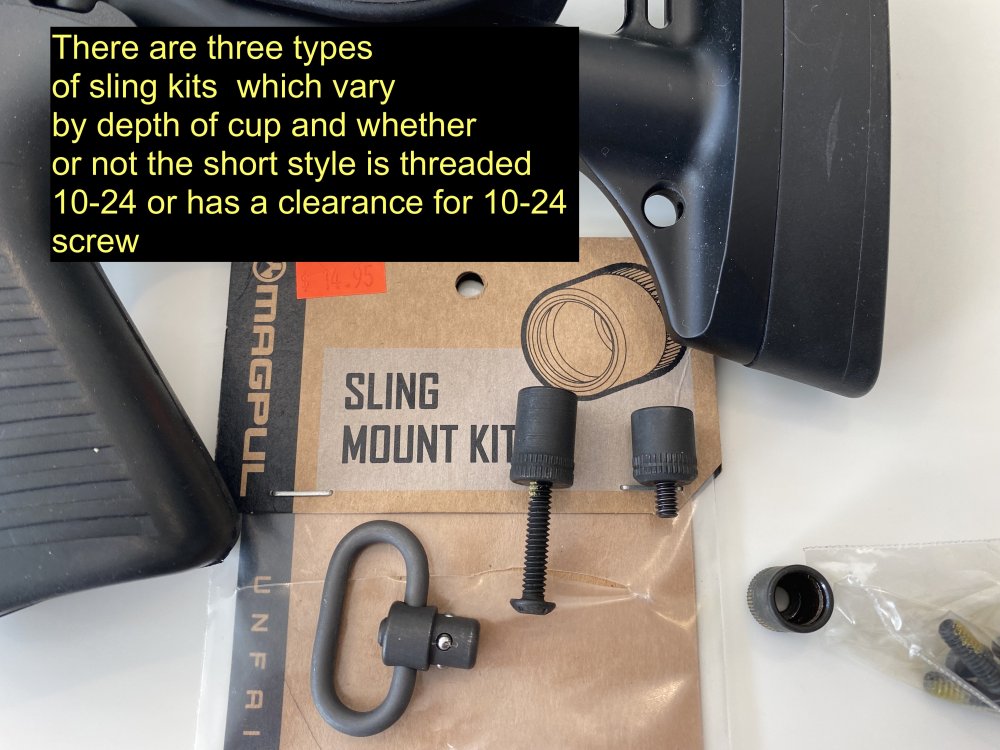

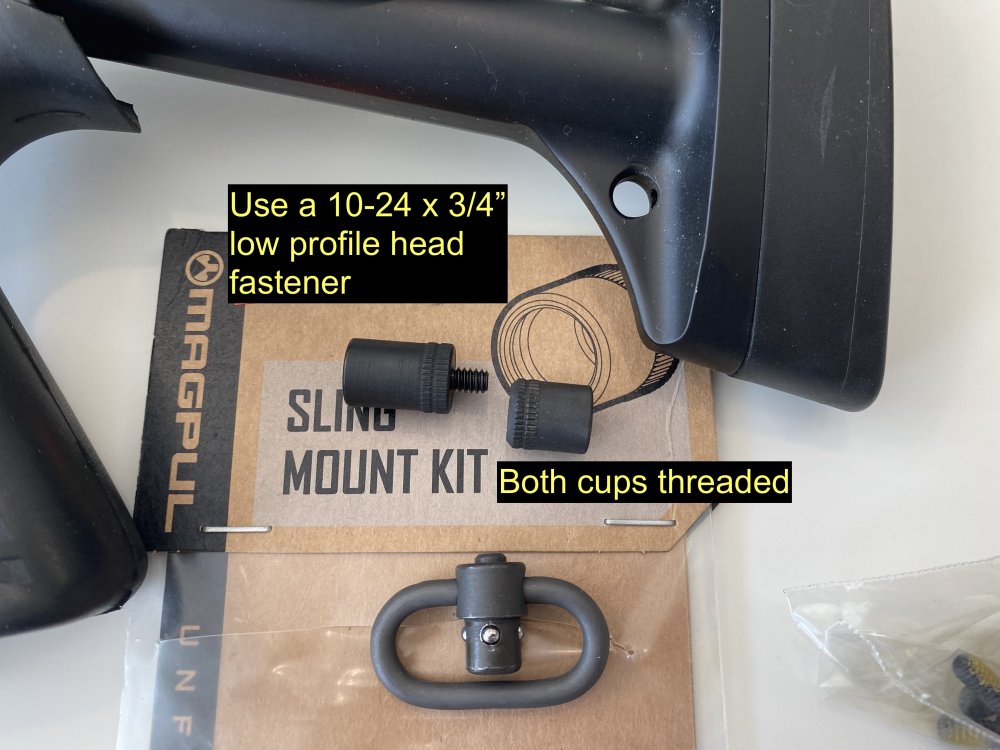

It occurred to me that it would be a more refined installation without any regrets by employing a bushing (either nylon / aluminum) to eliminate any possibility of QD movement and thus should be included in the task. I chose aluminum. This would eliminate need for any thin nylon washers suggested the first time around and because the bushing is proud a few thousandths on each side, it will be the bearing surface for the backside of the QD cups. The bushing was gently tapped right in place, use a nylon head hammer to avoid marring your gun art. Final appearance looks like something the factory would envy functionally and aesthetically.

-

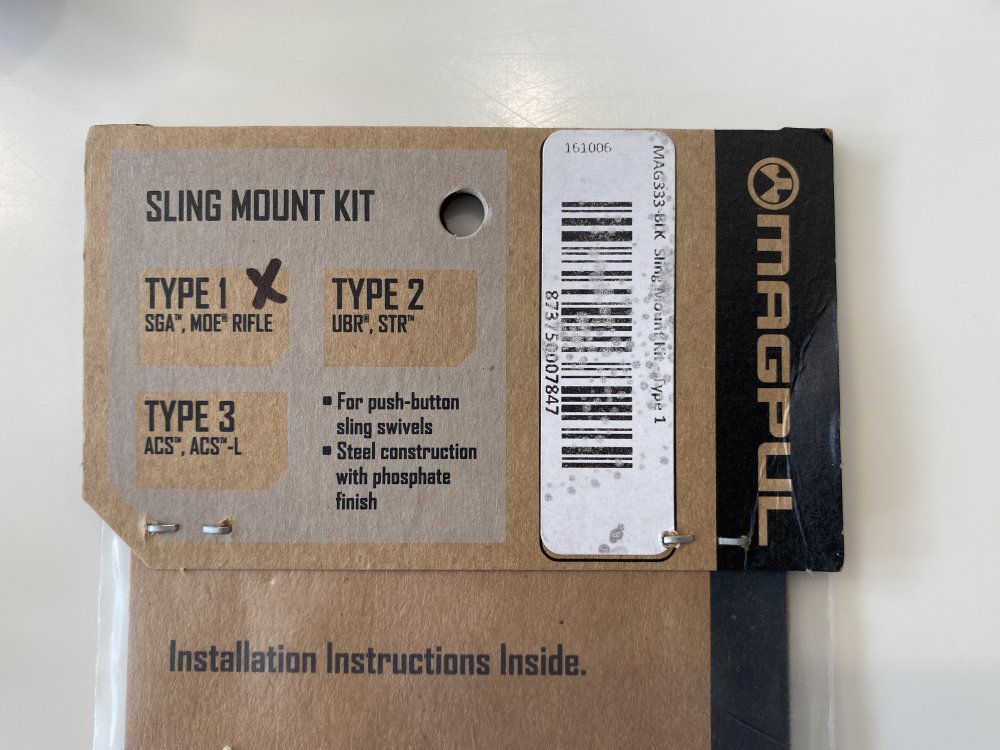

I was minding my own business this morning and wondered myself how to make it a clean installation. I prefer the sling mount at the grip level as it balances better for me when used. I would keep it simple / inexpensive by just using asymmetric Magpul flush cups, both threaded. It does not permanently mar / modifiy the hole. Consider using a thin nylon washer on either side between stock finish and the cup surface.

-

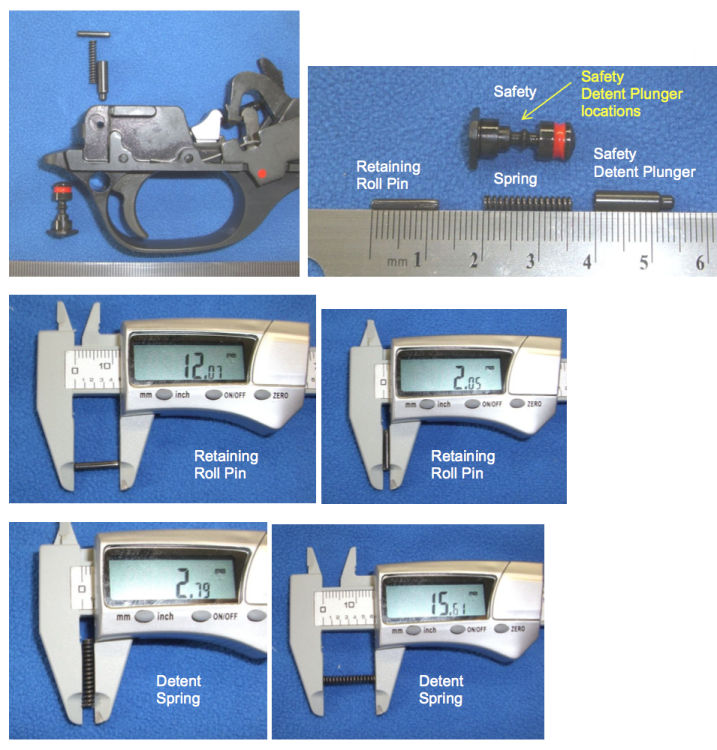

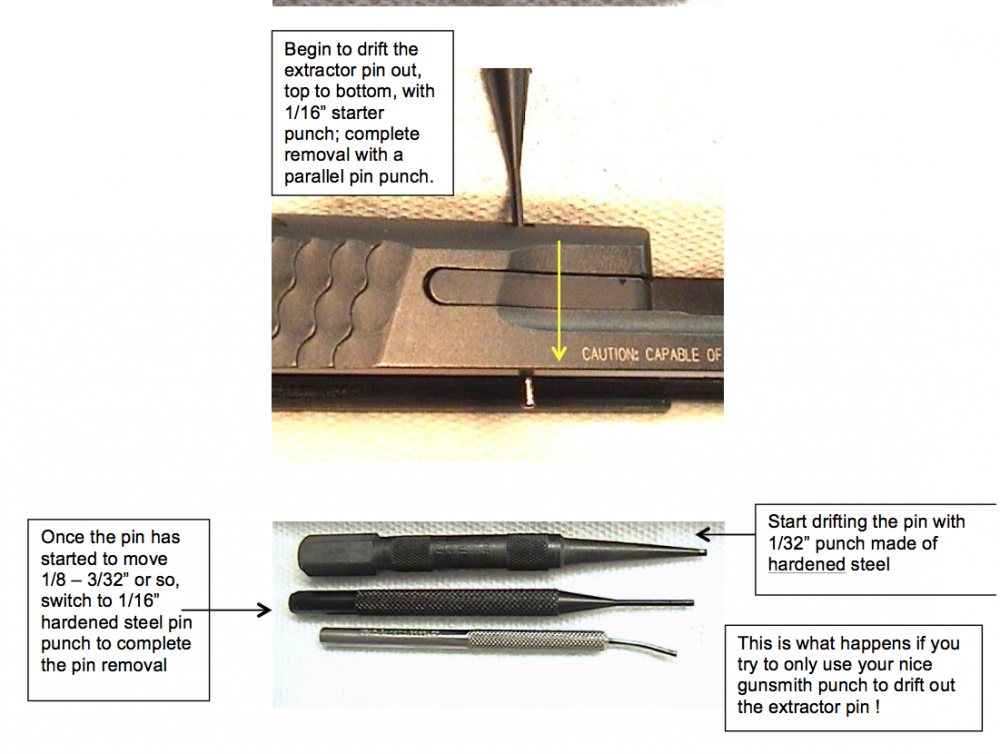

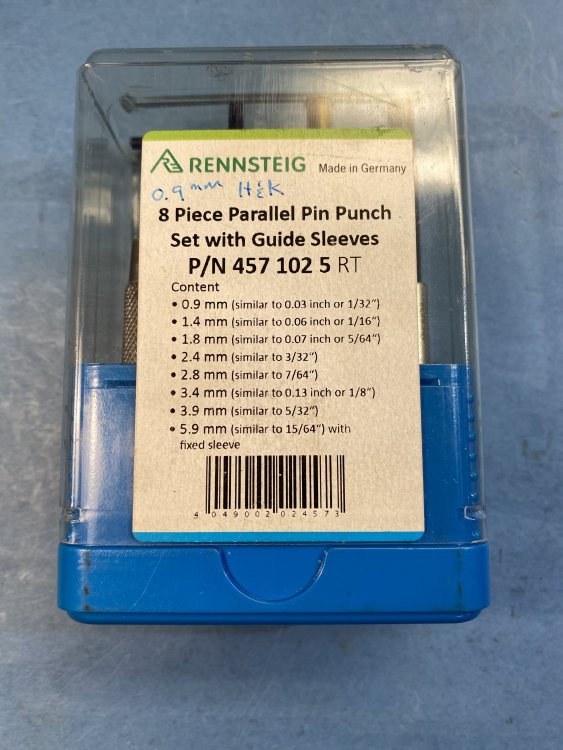

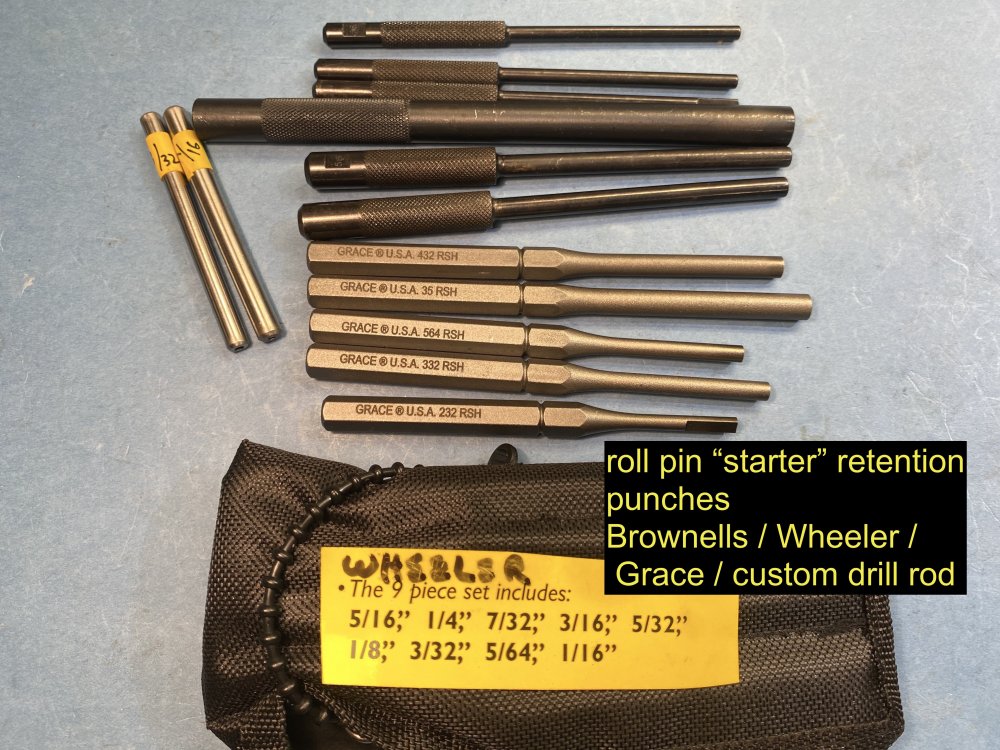

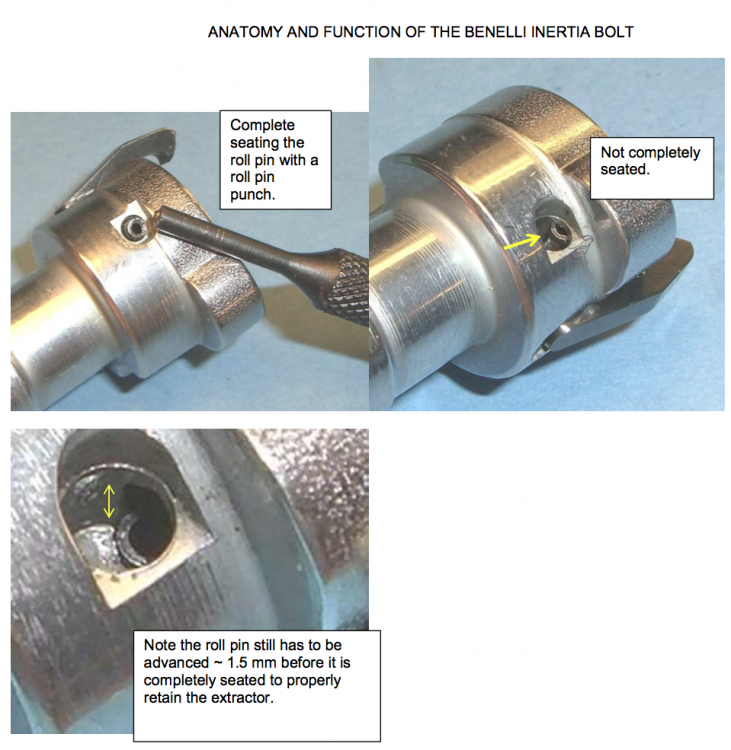

Early model S&W M&P pistols used small diameter solid pins to retain the extractor; like most mfg. a hydraulic arbor press with a few thousand psi runs thepin in perfectly within a matter of seconds, removing it was another matter. S&W eventually switched to a roll pin which is much easier to exchange; for the same reason SigSauer did similar pin conversions for their firing pin position retaining pin. For tight solid pins in particular, after applying some Kano Kroil for a few minutes, use the tapered starter punch (Wiha / Lyman / Proto make good ones) just to make the pin move a few millimeters, then switch to short shaft parallel punch then the longer parallel punch as needed; this sequence will save the thin punches from destruction. The silver lining is that you can take your bent pin, shorten it now and you will have the first member of your short punch set. The Rennsteig parallel punch set is clever in that an outer sleeve that supports the punch pin slides along its length, so you can begin with a "short" shaft punch exposed / supported so as you advance the length of the pin into the pin hole being removed, the pin hole walls themselves now continue to support the shaft of the punch. I made a set of brass roll pin punch holders.

-

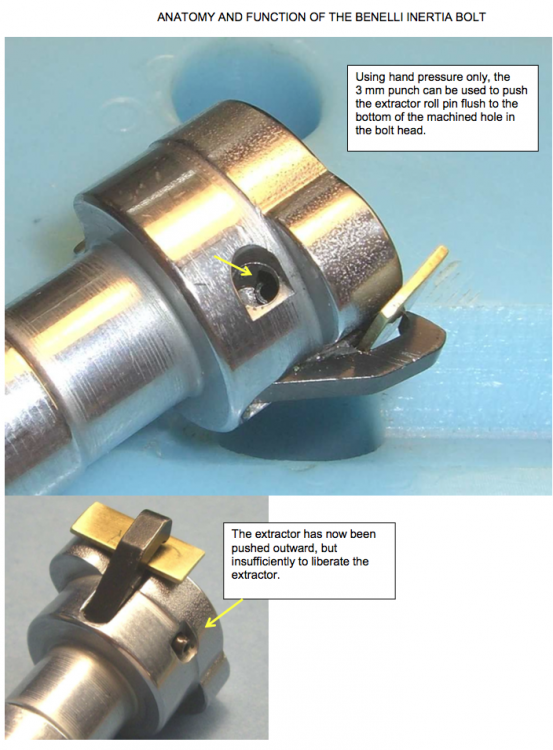

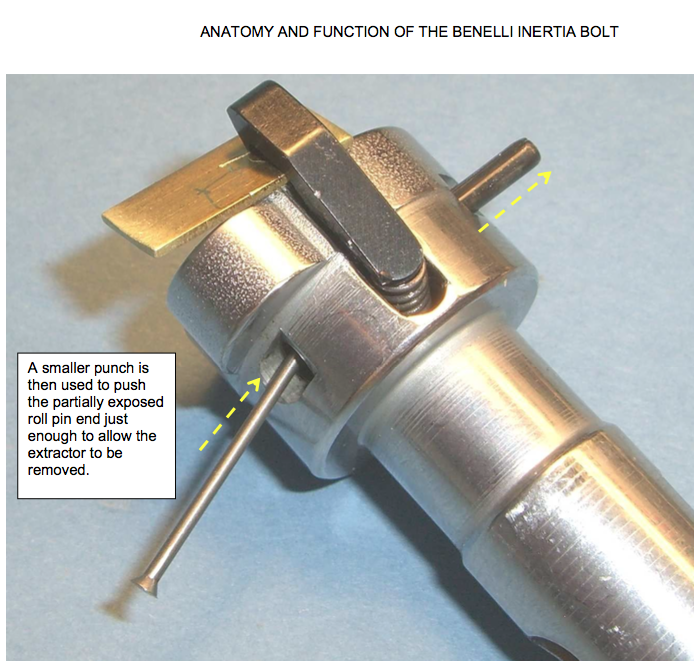

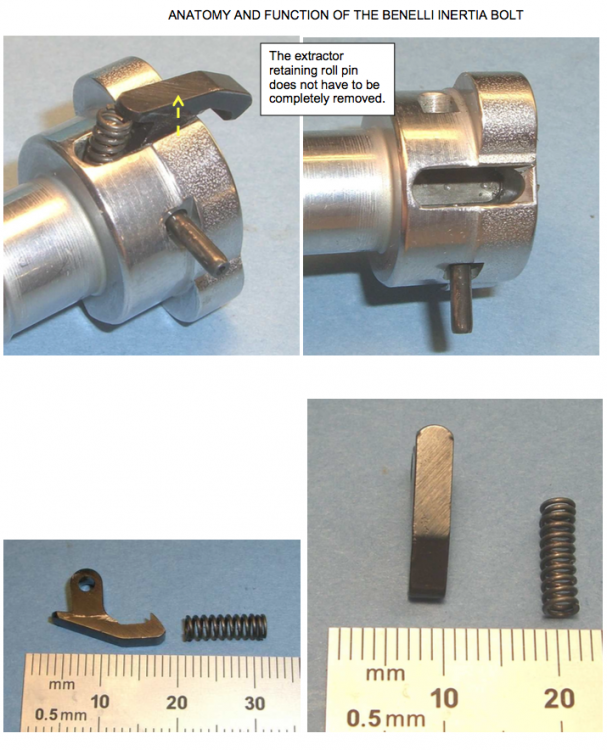

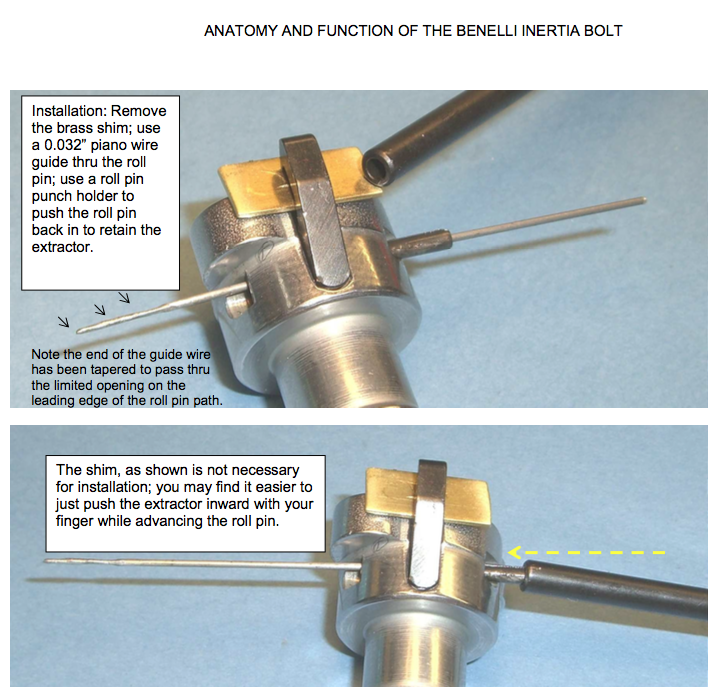

Pushed the roll pin out by hand as noted about, first step. Never used a nail as a punch. Notice that small diameter punches will deform like virtually every time use short shaft punches to get them started, note the short shaft roll pin punch used. You can get blank screwdriver handles and bore them to fit the punches when its not necessary or impractical to be beating on the punch with a hammer. I make a habit of using the correct punch application to avoid marring the gun art. Some examples of specific punches shown above.

-

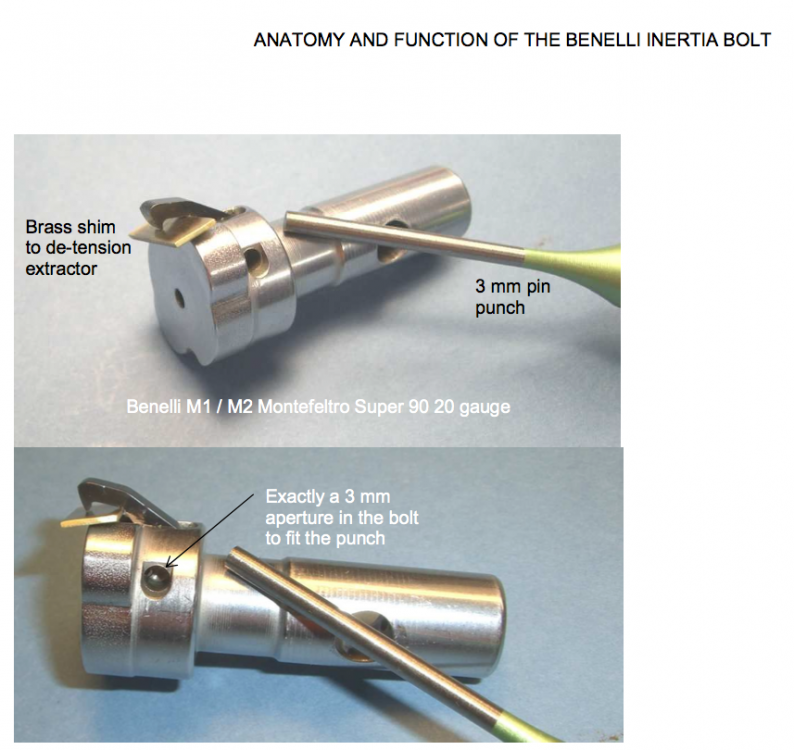

This is how I remove / install Benelli "Montefeltro type" rotating twin lug locking bolt head extractors.

-