-

Posts

4954 -

Joined

-

Last visited

-

Days Won

312

Everything posted by StrangerDanger

-

Benelli M4 -- Receiver Extension Removal/Reinstallation Guide

StrangerDanger replied to StrangerDanger's topic in Benelli

I looked at pictures of the M4A1 supernova stock and it definitely looks like it uses the same pistol grip portion as the regular M4. Its rare to find pictures of the left side. You can see the notch on the left side of the grip where the unlock button sits when the stock is fully collapsed on the M4 model. Personally I'm not a big fan of the M4A1 "upgrades". So converting it to have a traditional stock is a solid choice in my opinion. The enhanced RXArms extension is the way to go! -

Benelli M4 -- Receiver Extension Removal/Reinstallation Guide

StrangerDanger replied to StrangerDanger's topic in Benelli

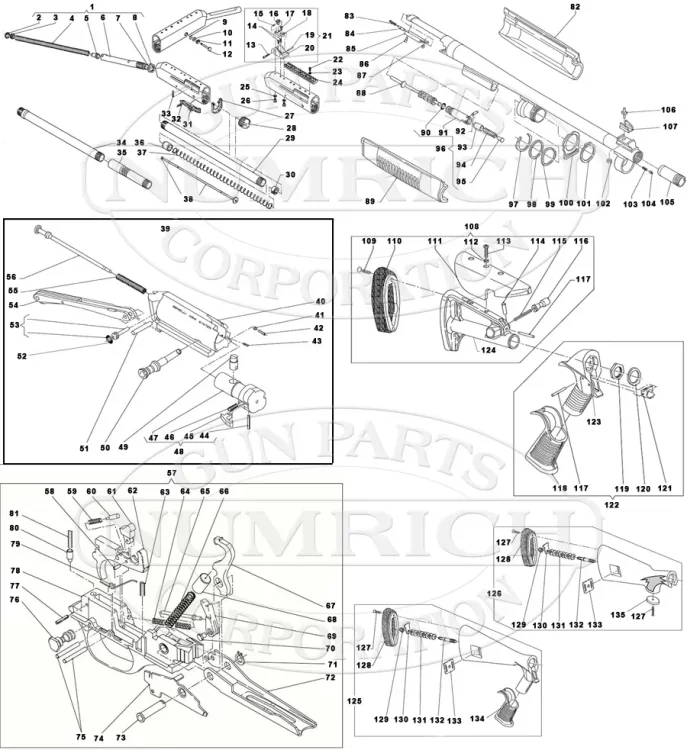

That piece fits inside the pistol grip and applies tension as you tighten the grip onto the receiver extension. It's part #120 on this picture. -

I forgot about the safety spring depressor tool he made too. Here’s a picture of the tools. Hope he’s doing well. I know he traveled internationally for work.

-

Never used the factory tool, but the tools made by the forum member here named Vertigofirearms are the absolute best. He made tools that are Magnabit format to attach to your favorite driver. He made ones for removing the screwed in plug in the bottom of the receiver extension and for disassembling ARGO plugs. Both are an absolute joy to use compared to my old janky methods. Every time I disassemble a clients M4, I’m thrilled to use these amazing tools that fit absolutely perfectly. They have a special place on my tool bit holders. The Argo tool is best used with a vice so that you can press the tool into the Argo plug and remove spring tension. You then orientate the plug so the pin simply falls out the bottom once the right amount of tension is pressed in. The receiver extension tool is like a perfect socket that fits into the notch on the plug. You can easily get the most stubborn of plugs out with it. Unfortunately I haven’t seen him on in a while. I know for a while he had a small website and was selling them. They were expensive, but they were basically bullet made pieces of art.

-

Benelli M4 -- Receiver Extension Removal/Reinstallation Guide

StrangerDanger replied to StrangerDanger's topic in Benelli

I haven’t handled one to say for certain, but I imagine the internals are the same so they could remain compatible with the pistol grip stock and field stock. I can’t imagine why they’d force themselves into making new parts. However, we are talking Benelli here… -

Rx Arms Benelli M4 M-LOK® Heat Shield (for Polymer Benelli M4 Handguard)

StrangerDanger replied to RxArms's topic in Benelli

Glad to see this is progressing! -

Installing a Limbsaver 10403 on a Benelli M4 Collapsible Stock

StrangerDanger replied to StrangerDanger's topic in Benelli

The Airtech is nicer. It will work on the fixed stocks or if the end user was willing to give up the fully collapsed position since you can’t drill into it and expect it to provide the same recoil mitigation. But yeah, they do need an adapter plate like the Noveske one the last I recall. -

You'll want the one labeled "Dark Grey" to match the phosphate finished M4s.

-

Awesome deal!

-

Benelli M4 Stock Handguard Light + Sling Mount Options

StrangerDanger replied to m4prime's topic in Benelli

RXArms is developing a heat shield that doubles as a MLOK mounting position that will permit the user to push a light mount out while still using the oem handguards. Currently they’ve hit a production delay the last I read. I believe the user must use their top rail mounting solution which acts as a rear boss for the heat shield. So it is kind of involved and expensive in comparison to the IWC mounting solution. It does have the potential of being a better system since the user can move the light farther forward to minimize barrel shadow issues. I still need to see in person how the remote switch integrates. Or if I’d have to modify the oem handguard for the activation system from something like the Unity Tactical HotButton. I still tolerate the Mesa Truckee on my setup with an IR head, but as you mentioned, it sucks. -

Benelli admins smartly assigned a few of us as moderators so we can kill the spam and moderate the usual forum stupidity. The little shield on the user profile picture indicates who is a moderator now. That way we can delete the crap on nights, weekends and holidays where Benelli staff aren't going to be around. Sukhoi_fan and I were assigned as them. There might be more, but I haven't seen them.

-

If it causes problems, Benelli will fix it for you, but just cosmetics, they probably won't do anything. You could try running it by their customer service.

-

Certainly not the best looking bolt I've seen, but it shouldn't cause you any functional problems.

-

Another choice for you guys. What do you load with?

StrangerDanger replied to John Doe's topic in Benelli

My M4 sits ready loaded with Hexolit32's. Its primary role for the past decade has been for bear problems. They'd be great for folding a skinwalker in half if you sprinkle white ash on them. Kind of a funny story, we have like 28 4K cameras around the property all hard wired into a NVR with a bunch of data storage. One of the cameras is mounted at the public road facing down the street. These are paved roads but just wide enough for a single car to drive and have a mix of Ponderosa pines 120' in height mixed with oaks that enclose the road. It is extremely dark since most of the sky is occluded by the tree cover. Very few have any active porch lights on and there are very few houses out here to begin with. I was sitting at the computer at night, and a secondary laptop runs the camera feeds to my right. I notice some movement on the camera mentioned and double click it to bring that view full screen. On the screen at night in black and white IR is this buck mule deer with an impressive rack right in front of the camera standing on its back legs walking slowly towards the camera. Like it was squared up with the camera. Its front legs were bowed out like the pictures of kangaroo's you see ready to beat some ass. In the IR light, deer eyes reflect light back so its eyes looked like they were glowing. Its fur was all messed up like it had been in a fight, or maybe it had that deer wasting disease. It felt like it was standing there for five seconds squared up but it was probably a lot shorter. I wish I had saved at least a picture of it. For that split second that I thought skinwalkers might be a real thing, I was reaching for the Benelli. The Hexolit32's are amazingly low recoil full powered slugs. I shot some old 1950's steel car doors and they whistled right on thru into the cab. If you clipped any of the supporting frame, they'd deflect and pool ball their way into the cab. -

Shorter the overall length in a tube fed gun, the fewer rounds you have available to feed from. So you end up with diminishing returns on a semi auto. At a certain point, you might as well just get a short side by side and eliminate the complexity of the semi auto. On the M4, you'd be stuck working around the receiver extension, so you're always going to have that awkward angled extension poking out.

-

M4 14.5" Prototype barrel - Who needs one?

StrangerDanger replied to benelliwerkes's topic in Benelli

Interesting... Looks like it has proprietary gas pistons too. -

No sling mount kind of sucks. Not a huge fan of the Mesa Tactical Urbino style attachment system for the stock. You had best be really careful tightening the bolt into the receiver extension. That snap ring will not prevent the stock screw from backing out during disassembly. Do not use thread locker on this bolt or you’re going to have a really bad time. The stock screw will come out of the receiver extension and be stuck on the end of the attachment bolt deep inside the wood stock. Not a huge fan of how they carved the handguards. They didn’t use the same piece to keep the grain of the wood consistent. Most Benelli owners would pay more for a better made product.

-

Sounds like you got Mesa Urbino’ed. I’m glad you were able to get the stock screw out. These stock screws were never meant to have a bolt put in them like this. That snap ring isn’t designed to handle the torque of a bolt. It’ll pull right out of the extension since it’s barely held in place by the race cut in the threads. I definitely would not use Loctite on these threads. I was hoping they had copied the oem style attachment system, but it seems they cheaped out sadly.

-

First time I've seen one of those screws sheer off. I'd recommend contacting Scalarworks. I'm sure they'd at the very least replace the screw. Do you think you could notch the screw stump so that you can back it out with a flathead?

-

Beautiful. When someone gets them in, please weigh them.

-

M4: Carrier Comp Charging Handle For Sale - Worth it's weight in gold?

StrangerDanger replied to ArizonaM4's topic in Benelli

I had one several years ago and had no interest in selling it until someone offered me 400 dollars for it around 2018. Used with minor scuffs and all. No regrets selling it. -

It's a V7 2055 lithium aluminum receiver set, but this is just the AR15 set. V7 sadly doesn't make a 2055 in AR10 yet. Total weight is 7 lbs 6 oz without a magazine. The MAWL is pretty heavy at around 10 oz. The newer version cuts about a half pound off of the overall.

-

Agreed, and thanks. No point to have a MAWL without night vision. I live pretty remote so my backyard is all BLM land on a forested mountain with old mines scattered around. For part of my PT, the dog and I do night hikes under night vision only. Preferably nights with zero moon or when it’s cloudy. It’s fun to creep and sneak up on mule deer and elk. We have a three mile circuit we do where we never touch the white light for the entire trip. Having the whole trip is an amazing view of the night sky as a bonus. When you do it a bunch you really dial in your sling setup and belt arrangement for creeping mode.

-

I shoot right handed primarily, but I’m ambi. I write left handed. It’s just easier to default right for guns. Plus I’m right eye dominant. Those aren’t HotButtons on top of the rail. They’re integrated buttons on the MAWL. Bumping the IR is less of a concern since no one can see it unless they have night vision equipment. Plus they’re pretty well protected in that valley. Using the violin style loading or the Benelli might work out then for you. I never liked taking my firing grip off of the firearms personally. If it works for you, use it. Nice build on your rifle, btw.

-

Detachable Shell Holder (Mark Precision Design)

StrangerDanger replied to Ihrinwe's topic in Benelli

This looks very similar to SideArmor carriers. They were extremely heavy and covered in sharp edges. Why they didn’t round over all the hard edges, I’ll never know. You’re adding a lot of weight and thickness to the receiver. Carrying the extra weight isn’t a big deal, the issue is how much you’re slowing the shotgun down as you add extra weight. It’s easy to swing past a target due to the extra mass. Shotguns should be super easy to point and swing from target to target. While it is nice having rounds with the shotgun, you’re better served having the shells on your body and not hung on the shotgun. An arrangement of speed feed pouches on a belt load the shotgun significantly faster than cherry picking rounds one at a time from a side saddle of some sort. Amateurs can easily grab two shells at a time and feed them in. Pro users and fit 3 and 4 at a time depending on hand size. Most want something available for the bump in the night situation where you don’t have time to suit up like the Commando meme. Where you’re lucky to have shoes and pants let alone belt pouches. For this, I sling a bandolier around the shotgun wherever it’s staged. One bandolier can hold like 55 rounds maxed out and is easy to sling over your shoulder before you engage the skinwalker.