Leaderboard

Popular Content

Showing content with the highest reputation on 07/08/22 in all areas

-

- UPDATE I received the rail earlier today. It was unboxed and inspected. First impressions was that it felt really light in weight. The rail looked good, there were no sharp edges or machining/finishing issues. I unloaded my M4, disassembled it and proceeded to follow the instructions. The instructions are very basic but I had no problems following them other than having one question. I called Midwest Ind. and spoke with Sean (Ext. 226). I felt that they left out one step that might have the end user questioning the instructions. I would've changed step #5 to read unscrew the 4 mid collar screws and the 2 rear collar screws and remove both the mid and rear collars. Again, it was easy to figure out but it would've saved me a call. The installation required a torx and socket key which was included. Once I got everything lined up and tightened down it felt rock solid. I checked for any flexing of the rail and it didn't move. At this point I backed out the screws, hit them with a dab of blue locktite, torqued them to 20in lbs and gave them some faint witness marks. Now that it was installed, I took a few minutes to do some presentations from both the low and high ready just to get a good feel for it. I have average sized hands and it didn't feel to fat or bulky so this was a plus. I then added some Magpul rail covers that I had laying around and it felt even better with the texturing. Again, it didn't feel bulky with the rail covers. I threw on a modlite but have to wait for the mod button mlok adapter to come in. My concerns about the pistons being exposed were put to bed. Most of the pistons are housed inside the rail. In regards to disassembly/reassembly, nothing will be as fast as removing the mag cap and popping off the forearm panels but I realized that I don't normally disassemble often so the necessary bits will be added to my range bag just in case. To be honest, I probably have about 400ish rounds through this entry barrel and I've yet to clean it. It just gets some lube from time to time. Over the next few range trips, I'll monitor if there's any issue with fit or function, If the screws start to walk and just overall the performance. First impressions for me are positive and it will stay on my M4 unless something changes. Attached are some pics. These are just my opinions so hopefully this helps some. I'm off to the range2 points

-

1 point

-

Sent the picture to Benelli and got a return authorization. I could buy the part and try it myself but I figure if it is this unsatisfactory from the factory then they should be the ones to fix it. Going to UPS to send it out today. It doesn't even feed shells since the lifter doesn't go all the way up.1 point

-

Wow, that's pitiful. I'd, for sure let Benelli know. At least send them an email with your photo showing the poor quality control. This shouldn't be on you to fix, make them responsible and ask directly how they want to fix the problem.1 point

-

Thats frustrating. It is a great looking rail minus that. I will stick with my IWC mount and tango oem stippled handguards due to this.1 point

-

So...do any screws need loosened or removed to strip the weapon? Or is it just easier if done?1 point

-

Not bad. Looking forward to hearing how it does when you push some rounds through it.1 point

-

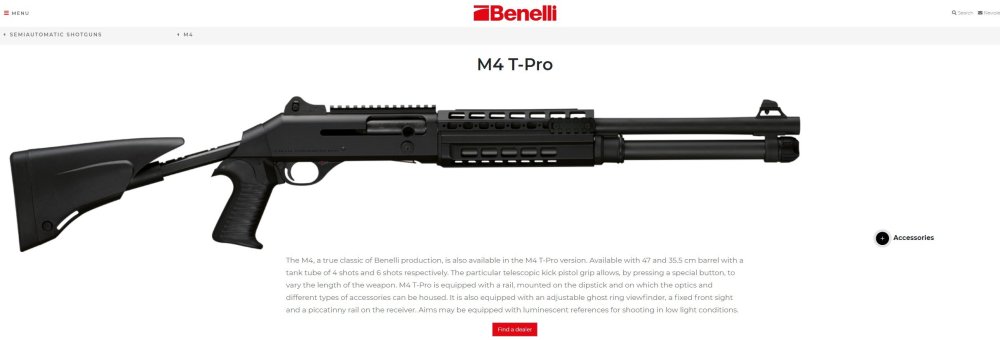

You can get a factory Benelli pistol grip stock or if you want a shorter length of pull, you could get a mesa tactical urbino. As far as a side saddle goes, you’d probably be best served with one of the shotgun cards velcro type setup to avoid any cycling issue’s. I use Esstac but there are also a couple other quality manufacturer’s people also recommend.1 point

-

1 point

-

Looks like the foregrip will allow better light placement to eliminate barrel shadow and expand options for pressure pad/modlite pad placement, cleaner wire routing etc.1 point

-

The Briley fore end doesn't require screws to hold it in place, it covers the pistons and acts as a heatshield as well. It does add some weight but I'm not humping it over the Afghan mountains either.1 point

-

1 point

-

Q: A: the design of the M4 doesnt make it easy to have the hand guard install or remove without having to remove some screws on the hand guard. best regards1 point

-

1 point

-

Gas blowback isn't the issue, but exposing the pistons on a COMBAT shotgun to the elements and impacts doesn't seem like a very good idea to me. The pistons seem to be pretty sturdy, but it's basically what the entire operating system relys on afterall. Not that my M4 has seen or ever will see any combat, but making them prone to impacts and unnecessary wear just seems like a bad idea. Probably not a big deal for home defence or competition use, but for "field" applications such as LE or hunting, I think it's less than ideal. Surely there's a reason why Benelli designed the OEM forend to cover the pistons too? Since almost every aftermarket forend exposes the pistons in some way, I guess there's a possibility I'm just beeing silly and my criticism is completely unwarranted. But I suspect the manufacturers are cutting corners to get them on the shelves as fast as possible. Just focusing on making it look cool, cause they know that sells. I mean some of the aftermarket forends are just plain lazy! Cool sure, but lazy nonetheless! This might not be as big of a problem as I make it out to be, but I still think it's less than perfect. And that bothers me, cause it can be! This one sure is getting close though IMO!1 point

This leaderboard is set to New York/GMT-04:00