Leaderboard

Popular Content

Showing content with the highest reputation since 04/23/23 in all areas

-

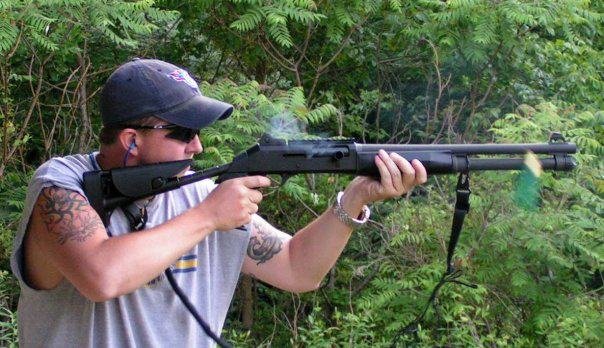

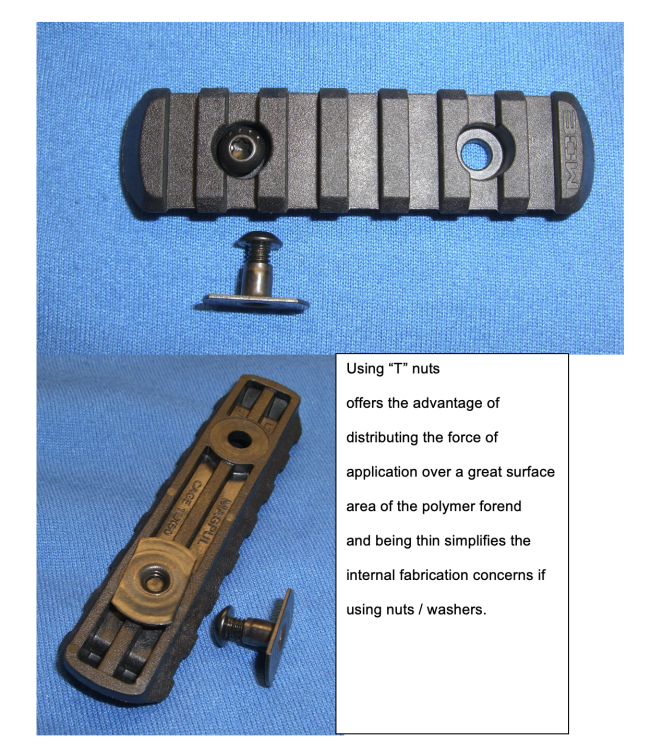

Hey all, Excited to announce this project, which I've been developing since Fall of 2022. Specifically designed to be fully compatible with the OEM Polymer 2pc Benelli M4 Handguard (Benelli 70117, and Benelli 70116). This brand new concept revolutionizes the way the Benelli M4/M1014 handles. It gives the user multiple options for accessory attachments, protecting hands from barrel heat, all while retaining the superior and unmatched ergonomics of the original Polymer 2pc Benelli M4 Handguard. Machined from billet 6061-T6 and mil spec hard coat annodized. Once installed, this Heat Shield offers fast, and tool-less takedown of the Benelli M4/M1014. Fully compliant with ARDEC Solicitation DAAE-30-98R-0401. It is not any slower to take down the weapon than if you didn't have the heat shield on at all. The design requires an Rx Arms Optic Mount to function (as the receiver optic mount has a boss hole which accepts the heatshield). Initially will be offering a mil spec picatinny rail, and RMR rail. To follow will be the aimpoint T2, and P2 rails in early 2024 it is looking like. All optics will co witness from close range to long range. If you are interested, you can sign up on the waitlist at rxarms.com. It is looking like Q4 2023 for availability. If you have any questions I'd be happy to answer anything I can.11 points

-

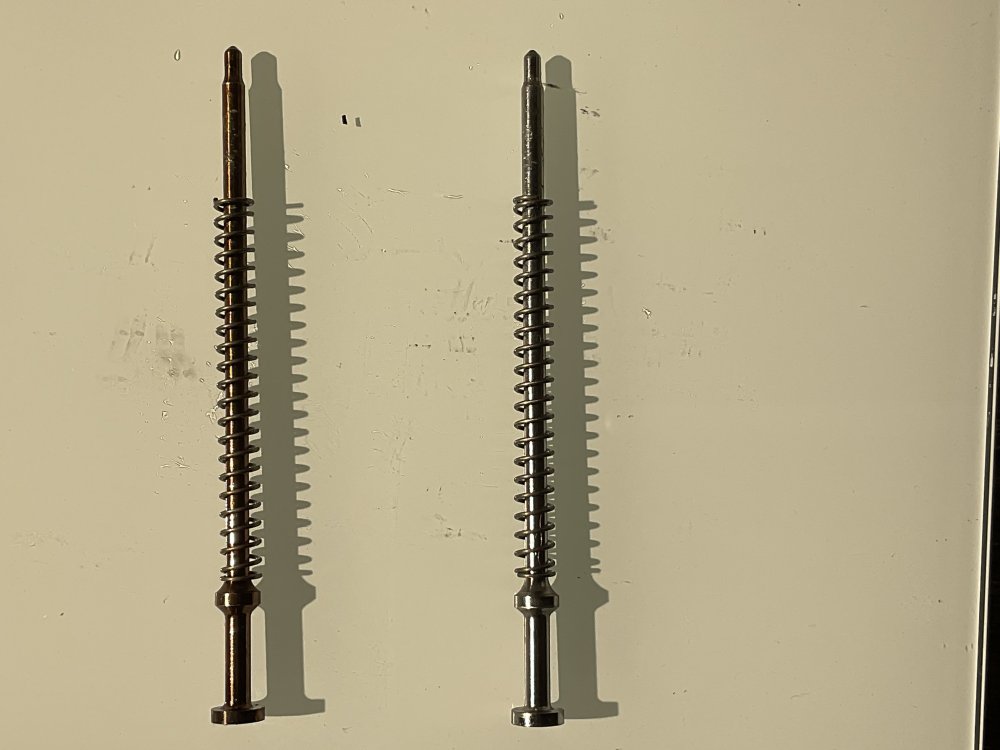

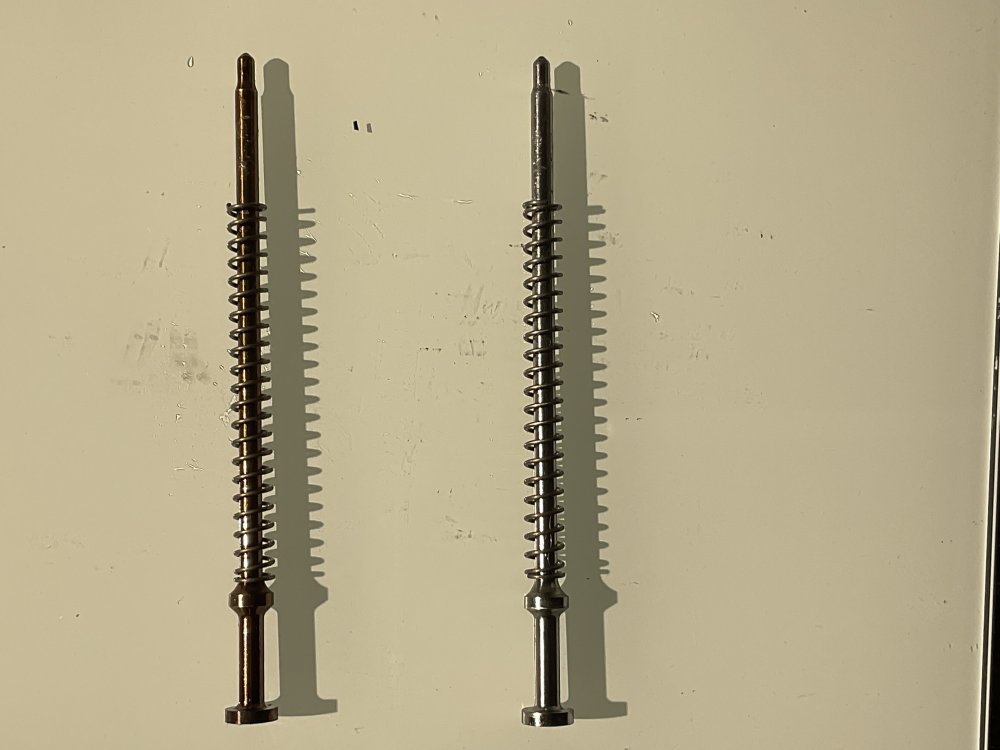

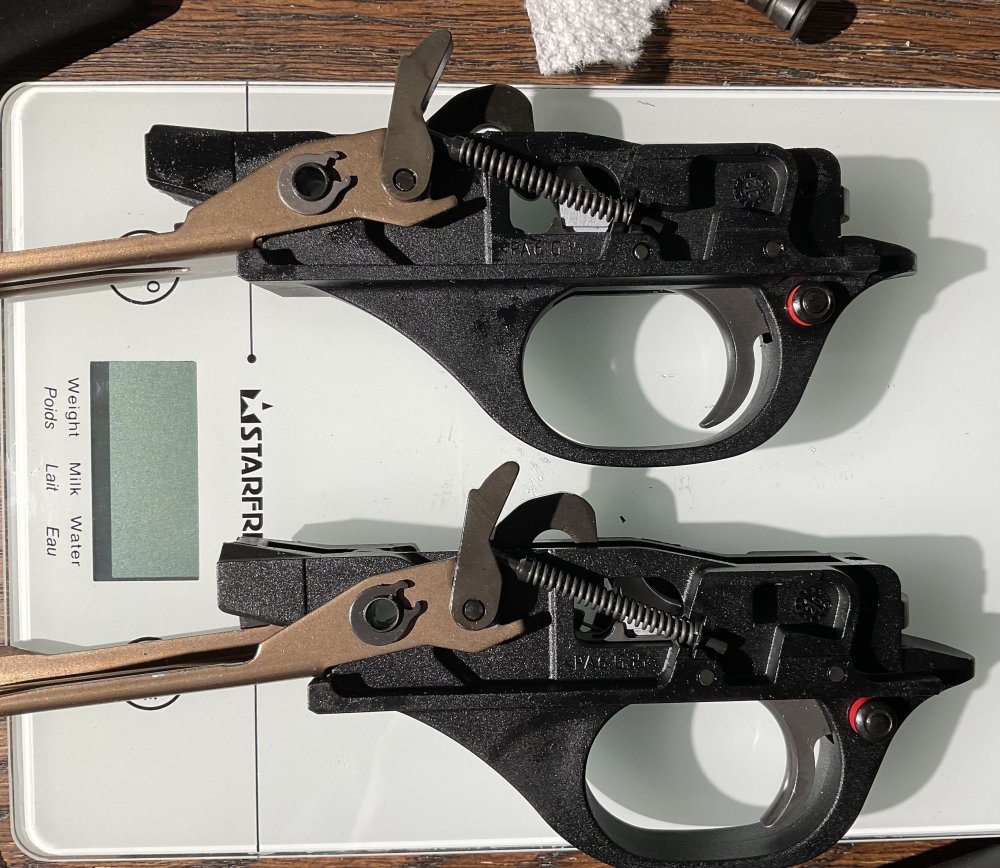

I thought it might be interesting to do a little comparison between my Dad’s 2020 M4, and my new (2023) one. After taking them both apart I took some pictures of the most prominent differences I found, so here they are: The piston plugs have a very different finish. The old ones have a polished steel look, and the new are a more opaque finish. Perhaps they tried to reduce visibility as they’re slightly exposed by the t-pro hand guard. The pins are also a little different, the old ones being a polished steel look, and the new ones having an bronze like coating. I found that the finishing work to the piston housing was slightly more refined on the older model, but this could be because of the difference in colour. There are some differences in the barrel assembly. You’ll notice that the pins are miss stamped in the newer model, I did see this on another fde t-pro, so it might be a prevailing change/mistake. Overall I would say the finishing work is close in terms of quality. I wish I had an even older model to add for more reference. None of the firing pin pictures quite show the finish change, but it’s much like the pins in the piston plugs. The old on has a polished steel finish, and the new one is a sort of bronze finish. The bolt head retaining pin has a larger notch in the new one. The bolt heads have slightly different identification marks, but in terms of workmanship they seem pretty close. My new one has some nicks on the bolt face that the old one doesn’t suffer from however. New Old There was a slight discolouration in the finish on the metal parts of the new trigger grouping in places. (New trigger group on top.) Everything else seemed to be pretty similar. The old pistons finish seemed like it had a more grey tinge, while the new ones had almost a green tinge. You might be able to see it in some of the previous photos, but I had a hard time getting a good photo of it otherwise. I’d be interested if anyone else has an old one they wouldn’t mind rating these against in terms of workmanship. Also, if anyone else has a t-pro I’d be interested to know if you’ve found that the internal parts of yours share the same finishing differences as mine. Cheers, and thanks for reading!9 points

-

I wish I could say more but I’m deep in R&D on a system that is unobtrusive, Will mount the light near the muzzle and comfortably mount a remote switch near the handguard. It also takes down with no tools. Im not ready to disclose more, and this isn’t a plug, but if you want details in the future you can sign up on my newsletter at www.rxarms.com (I only email out once every few months when new products are available).8 points

-

7 points

-

6 points

-

6 points

-

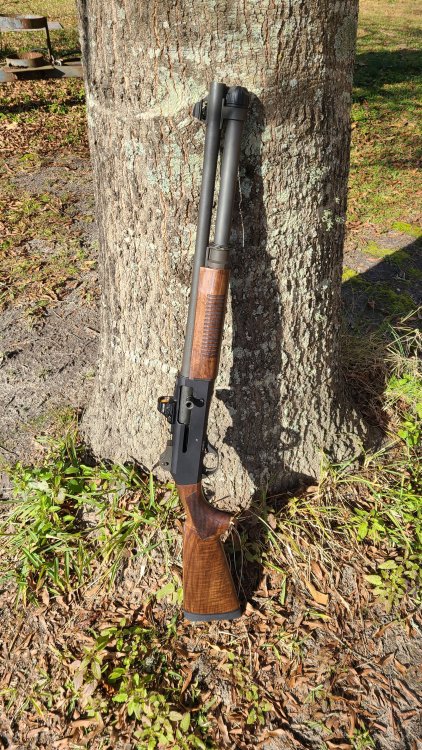

Been wondering if we’d ever have the option of buying wood sets. These are Panzer Arms from Turkey—one of the clone makers (“Turknellis”) that sells clone versions with these stocks. I wish Benelli made wood furniture for the M4, but it is what it is. Cheapest right now for $70 at PSA, and also available for $100 at MidwayUSA. Better pics at this site, but they are sold out. I’ll follow up once my set arrives. If they’re good to go, I’ll likely add QD swivels and a Limbsaver as I did here. If the finish is glossy I’ll probably also use steel wool to make them matte.6 points

-

I’ve been on the forum since 2007 and finally bought an M4, new, in 2010. Bought the Carriercomp tube back then, and subsequently used the Sidearmor rail when that was a thing. Got rid of that heavy monstrosity a while ago. Started with the fixed pistol grip stock, and then replaced it with the Mesa Tactical Urbino when that was released. Recently decided the field stock was better for me. Here’s where it’s at now: TRIGGER GROUP: OEM aluminum trigger guard (came this way in 2010) Shooting Sight NiB Benelli hammer Taran Tactical Accuguide shell lifter DMW enlarged safety RECEIVER: Loading port opening by RAS (Rose Action Sports) Enlarged circular bolt release button by RAS FFT Mil Spec Rail Midwest Industries QD Low Aimpoint T1 mount Aimpoint T2 RX Arms Benelli M4 Charging Handle Titanium BARREL & MAGAZINE: Carriercomp titanium magazine tube Wolff magazine tube spring Brownell’s magazine follower Benelli cylinder choke Impact Weapons Components Mount LBM41913 STOCK & HANDGUARDS: Benelli field stock Limbsaver pad 10403 Benelli Noveske flush QD mount x 2 Stock and handguards painted in Multicam by Branden at Custom Gun Coatings Blue Force Gear Vickers sling in Multicam, sewn QD push button mounts Blue Force Gear Sling Sleeve in Multicam6 points

-

6 points

-

Benelli would do well to apppoint a regular member with reputation to have low level admin power, honestly. What a crap shoot. a velocity filter would be useful, stopping members/IP from doing more than 2 new posts an hour or something.6 points

-

6 points

-

There will be some videos this summer from YouTubers. I’ll post links when they are up.6 points

-

6 points

-

This is one of those things where the theoretical meets reality. Out running a Benelli trigger isn't particularly difficult. But other than doing mag dumps into the same spot just to see how fast you can do it, it serves no purpose. (Then you start to play the game of "go as fast as I can without going so fast it doesn't work. You work on your timing and rhythm. Sure it can be silly expensive fun a for a few minutes, next thing you know you wasted 125 rounds and didn't really learn anything. lol) "Damn, I can't do something that never actually happens!" So it's a "problem" that's not really a problem. As to the WHY, it could be that the Panzer is over gassed (and beating itself to death). So the fact that it can do something you don't need to do might not be a good thing.6 points

-

6 points

-

6 points

-

6 points

-

No sling mount kind of sucks. Not a huge fan of the Mesa Tactical Urbino style attachment system for the stock. You had best be really careful tightening the bolt into the receiver extension. That snap ring will not prevent the stock screw from backing out during disassembly. Do not use thread locker on this bolt or you’re going to have a really bad time. The stock screw will come out of the receiver extension and be stuck on the end of the attachment bolt deep inside the wood stock. Not a huge fan of how they carved the handguards. They didn’t use the same piece to keep the grain of the wood consistent. Most Benelli owners would pay more for a better made product.5 points

-

5 points

-

Ordered mine on Tuesday evening when I saw this post - the furniture arrived today. Probably the fastest shipping from PSA that I've ever experienced...! Don't necessarily think I'll put this furniture on either of my guns, but it's an option for the future. I'll likely just stick them in the gun room and when some guy asks for these in eleven years I'll sell him my $900 set of wooden furniture... lol. Would be nice if there was some type of heat shield on the forearm as the wood is pretty thin and I can imagine it getting pretty hot with moderate usage. ll5 points

-

I’ve had to redesign the heatshield unfortunately. Problems started to occur after 1K rounds and had to go back to the drawing board after a few months of trying to remedy it. Hoping to have a whole new prototype for testing in January Feb.5 points

-

They typically attack forums on holiday weekends to sell their micro penis supplies knowing the forum moderator doesn’t do any kind of work off the clock.5 points

-

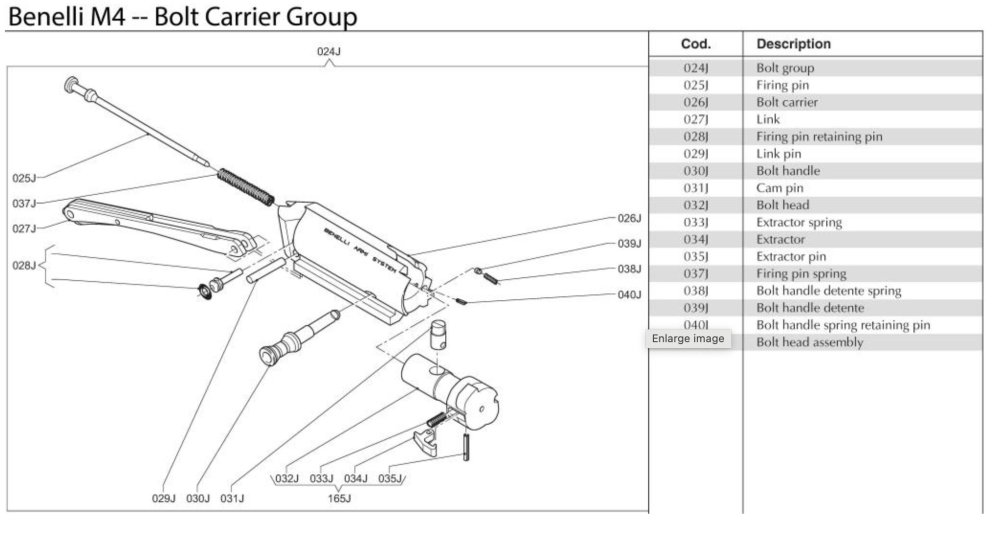

Over the past several years I have found many more Benelli with bolt heads that are full of debries - causing light strikes. This is one of many causes of the issue. Here is a series of photo's that documents the issue fairly well and how to eliminate this as a cause of light strikes. This could lead to better insights when deep cleaning your Benelli at the end of the year as well.5 points

-

5 points

-

Oil it. Then use the hell out of it. Scratch it all up. You won't notice the color change. If you wanted a static art display, then you didn't need a full length mag.5 points

-

5 points

-

I think this test is a joke compared to the 25k round test the USMC did. Who needs to test the M4 for 500 rounds? What’s the point? When I test products I’ll easily go through 500 rounds in one session, and this is after not cleaning the gun for the past thousand rounds. Sorry if I sound harsh but he’s trying to get click bait testing the most battle proven shotgun ever made. Meh.5 points

-

5 points

-

5 points

-

Wish I could lower it, but it’s an expensive piece to machine, it isn’t just an extrusion like other handguards, it’s machined from billet inside and out. It’s 16” long, and has some precision machining on it which is costly. as for the optic cost, new M4 owners won’t feel the cost as much as older M4 owners as they haven’t upgraded anything yet. Picatinny is the cheapest way to upgrade. I might adjust the pricing before offering it for sale, trying to make it as cheap as I can.5 points

-

Appears to be same/similar chemical structure and have same/similar appearance and benefits. From the email, couldn't attach jpegs for some reason View this email in your browser NT7™ & NT7 Plus™ The long awaited NP3 Replacement Coatings l In October of 2021, without any warning the NP3 family of coatings was discontinued from the retail market. We were just as shocked as you and we vowed that we would find a suitable replacement. Our goal was to find a coating that was similar in performance, chemical makeup, and corrosion resistance. Over the past 2 years we have enlisted the help of the top chemical engineers, process engineers, and coating specialists from across the country to help us with this tall order. Through this process we discovered that we actually had two problems to solve. First was the obvious, we needed a performance coating that could meet our strict requirements. Secondly, and just as important, we realized we also needed an applicator that we could trust to apply the coating. We were unsuccessful on both fronts. After much deliberation we realized that there was really only one option. The only way to get the coating performance we needed and to ensure that we could provide the service that our customers deserved would be if we designed our own proprietary coating and undertook the significant investment to build our own inhouse plating facility. I am excited to tell you that this is exactly what we did. Construction of our inhouse plating facility started in March of this year and barring any unforeseen construction delays will be completed by the end of August. **Please DO NOT SEND IN COATING ORDERS until we announce that we are accepting orders** We will be equipped to process: Steel, Stainless Steel, and Aluminum parts. We plan to be processing customer parts starting in September. The replacement coatings NT7™ & NT7 Plus™ will have very similar performance specs to the NP3 specs and just like their predecessors the “Plus” coating will have a higher corrosion resistance. NT7™ and NT7 Plus™ are based on a Nickel Teflon coating so they will have a similar satin Nickel appearance and the same low coefficient of friction and non-stick properties that we have all come to know and love over the years. We will be releasing pricing and more details about NT7™ as September approaches. Key Info: NP3 has been replaced with NT7™ NT7™ & NT7 Plus™ will be applied inhouse in our brand new plating facility Construction on our inhouse plating facility will be completed 9/1/2023 Please DO NOT SEND ORDERS NOW, we will let you know when We will release pricing and more spec's for NT7™ & NT7 Plus™ in the coming months We look forward to better serving you and your firearm refinishing needs in the very near future! Sincerely, Brian Wright President & CEO5 points

-

4 points

-

M4 is more robust. I have all 3, the berettas are a lot of plastic… M4 is heavier but can go through a battle field and still function if dropped, banged around, thrown around etc, to be honest I wouldn’t ever take a 1301 or a 300UP into a battle if the M4 was there as a choice. the berettas shine in sport shooting. Pick your poison.4 points

-

4 points

-

4 points

-

4 points

-

I have a bunch of shotguns and a few SBS included in those, so i didnt need this shorty but since when has a 'need' really mattered? A buddy from BUDS called and told me they had finally gotten in some TAC-14s in wood and i went down and grabbed one. I added a Mesa saddle and an old Remington sling. I put 50 rnds of 00 buck thru it and its loosened up nicely. It might just end up being my stand in the corner, bump in the night go to.4 points

-

Not sure why you are so upset about all of us making a reasonable complaint about the situation. If it doesn't bother you then great, move along, but please don't criticize me for having an expectation that a forum should function within its own stated capacity. I am not upset about a minuscule thing here. Please for future interactions if you could be so kind as to refrain from being overtly confrontational and bitter towards those who have standards for how a site is supposed to be run, I would greatly appreciate it. Thank you sir and God bless.4 points

-

How does one go about becoming a moderator? As mentioned here, there are a few retired gentlemen who can run it, and Im sure others who are on here consistently. Is there some way to register with Benelli in order to do so, or are they employees of Benelli?4 points

-

4 points

-

Hey all, We have an updated design utilizing the some engineering from the Titanium charge handle we offer. Coming in at a much lower price point due to the 7075-T6 for the handle instead of Titanium, and the same hardened stainless steel pin. Also using the same "anti spin" design, to keep the charge handle in place. Offering both a 0.55" handle coming in at 9 grams, and a 0.75" handle, coming in at 12g. OEM handle is around 12g. You can check it out at www.rxarms.com. Thanks!4 points

-

I’ve settled on what for me is the best light option. Inforce WML with IR and Strobe functions. It’s lightweight and blends into the Benelli railed hand guard. Nothing wrong with the Streamlight or Surefire options, but this seemed more useful for me, especially since I do have a PVS-14 setup to take advantage of the IR feature. I’ve been using the same tactical light on a FN PS90 for a few years with good results.4 points

-

4 points

-

Like many of you, I waited a long time to pull the pin for a M4. I just received a spanking new M4 LE H20. There seem to be two ends of the spectrum on the first things to do with a new gun, one end is to start blasting away, and the other is to field strip, inspect, clean and lube everything prior to firing. Being of the clean school of practice, when I got to the BCG, I noticed there was a chunk missing from the little o-ring that holds the 028-J firing pin retaining pin. See the pic, beautiful US made mil-spec o-ring on the left...damaged 0-ring on right. No problem, I thought, just order some spares... Welcome to the world of Benelli parts. Midwest has the firing pin retaining pin and o-ring for $6 plus $7.99 shipping, and Freedom Fighter Tactical has just the o-ring for $13 plus $16.50 for shipping. So between $13.99 and $29.50 for this o-ring? And of course, no one, not even Benelli, reveals the exact dimensions or where the o-ring is sourced. An internet search reveals that one common solution is to take the 0-ring to Home Depot, or order something similar on Amazon. The problem is that these o-rings are from China, which is why you can buy those 300+ o-ring variety packs for $10. Neither of these options seem very appealing, especially for a weapon that many owners end up sinking at least $3K in to. I have some interesting experience with o-rings, as I have owned two M35A3 6x6 over the years with the central tire inflation system (CTIS). Each tire has 11 locations that air can leak...and who knows how many more from the engine driven air compressor to the tires. So all this requires lots of o-rings. So when you go to buy parts for these old military trucks, each part has number, and a military spec that goes along with it. The US Army does not use Chinese o-rings from Home Depot. I also saw that some were suggesting Viton o-rings. These are great for hi-temp applications, but Viton o-rings are ineffective below 5 degrees F as they become hard and inflexible. Buna-N seals have superior abrasion and tear resistance, making them more suitable for heavy-duty industrial applications. So, after a lot of research, I found a source for USA made mil spec o-rings that are the exact dimensions of the 'unknown' Benelli o-ring that meets ASTM D2000, MIL-P-25732, SAE J200 standards. The Buna-N material and construction meet strict military standards, are resilient and offer resistance to tearing, motor oil, ammonia, ethylene glycol, isopropyl alcohol and mineral oil. The are sized to the SAE standard AS568. The temperature range is -65F to +275F. It doesn't seem that anyone knows what happens when these o-rings fail. They are called upon to serve as a friction wedge vs their usual job of sealing. The top of the firing pin retaining pin has a mushroom cap on it, and I am only guessing that it could back out until its hits the receiver wall for quite some time. But if it does back out and break, and somehow the firing pin is released...you are hosed. There are plenty of videos on YouTube where the factory rep easily removes the firing pin retaining pin with their fingers. If yours was not so convenient to pull out, and you pried it out with a tool of any sort, you should probably check for chunks out of the o-ring. You can also use a Glock tool to easily push it thru from the other side. There is really no easy way to buy just one Buna-N mil-spec o-ring. So I ended up with a few more than I could ever use. If you are interested in one of these for $3.75 & free shipping, send me an email at [email protected]4 points

-

RxArms, thanx for doing this stuff! Hope you at least make enough $$ to keep you interested in doing this type of thing for a while. How much does the guard weigh? Looks awesome BTW, nice work! Have you thought of doing QD cups on the front mount? Or is that covered by the M-Lok?4 points

-

I received it and it is immaculate, I love it! Brightt is a great person to deal with, does what he says he will. He has my highest recommendation should he decide to sell anything more.4 points

This leaderboard is set to New York/GMT-04:00

.thumb.jpg.79cc541042b39375fb444c95d1a6cd7d.jpg)