Leaderboard

Popular Content

Showing content with the highest reputation since 03/24/24 in all areas

-

Nevermind, I should have checked RXarms... he's killing it with the custom M4 parts.2 points

-

2 points

-

So I was gonna have JK Armament make one but decided not to since their suppressor mount is made to be thread locked on and only adds about a half inch to the length. A cursory glance at other thread protector manufacturers didn't turn up anything. Maybe try McMaster Carr.1 point

-

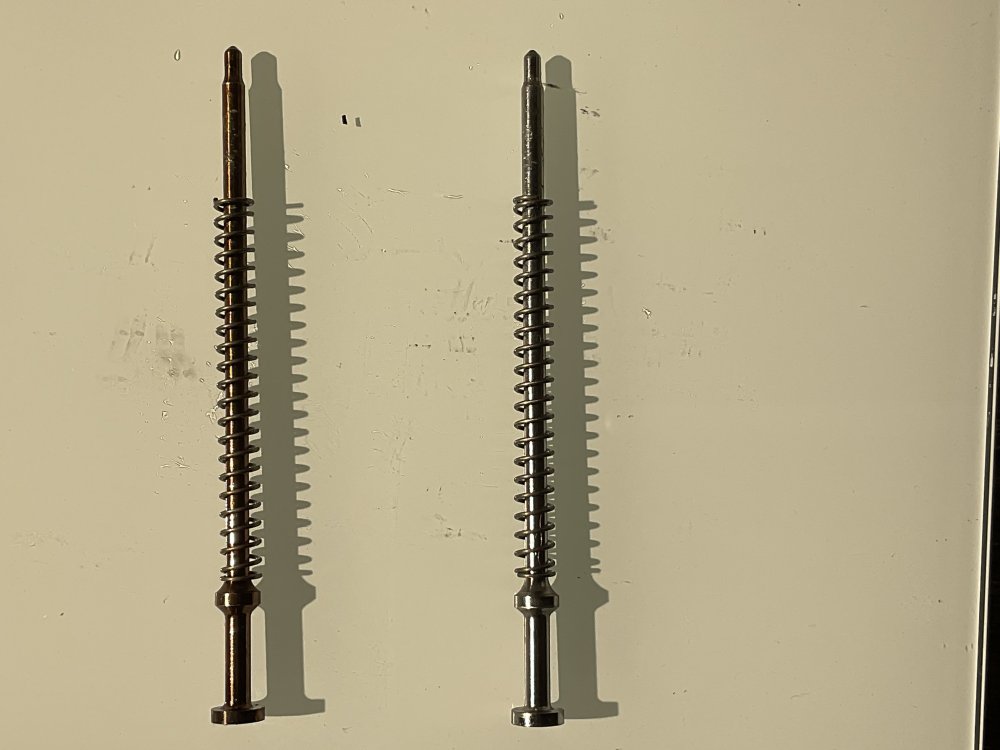

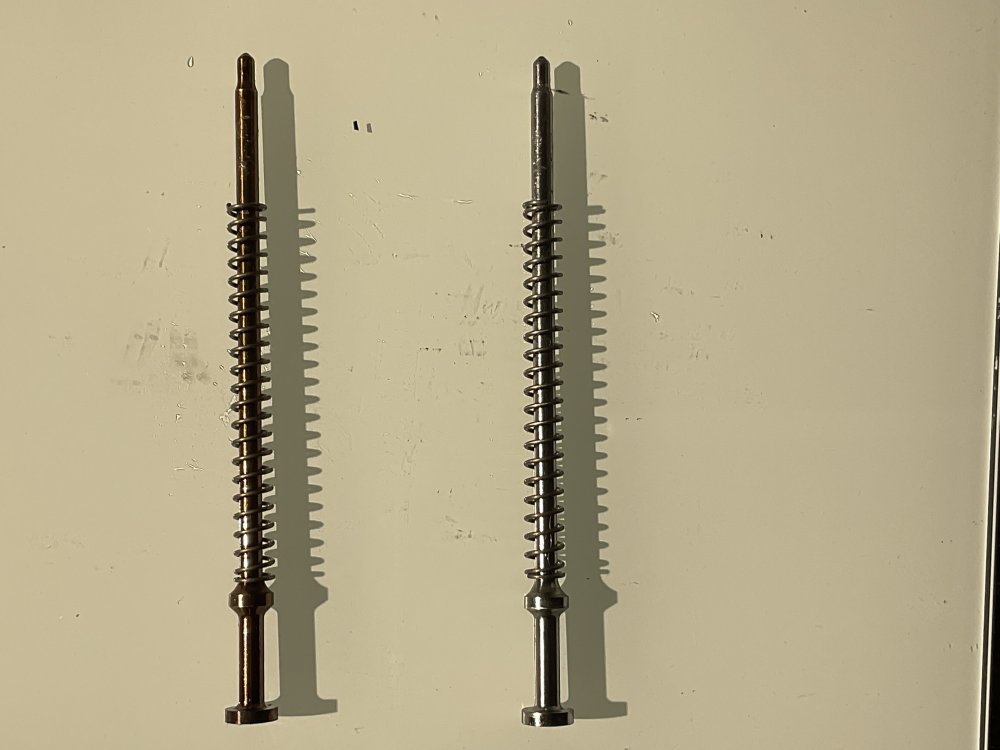

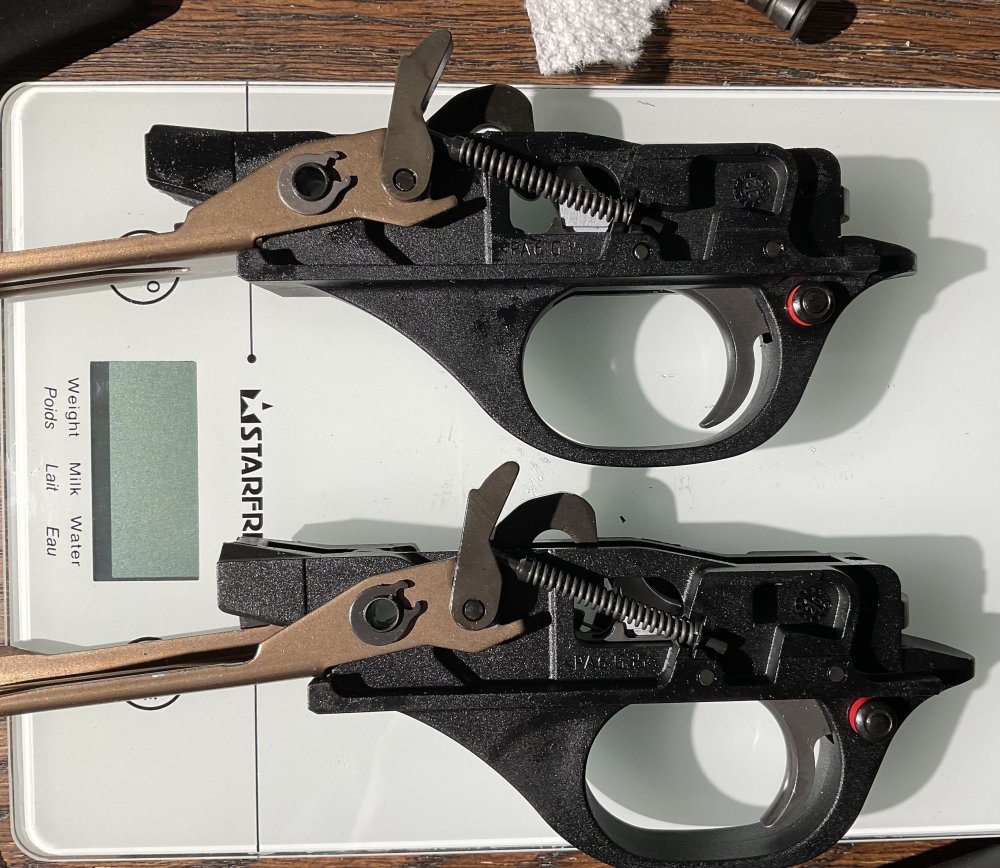

I thought it might be interesting to do a little comparison between my Dad’s 2020 M4, and my new (2023) one. After taking them both apart I took some pictures of the most prominent differences I found, so here they are: The piston plugs have a very different finish. The old ones have a polished steel look, and the new are a more opaque finish. Perhaps they tried to reduce visibility as they’re slightly exposed by the t-pro hand guard. The pins are also a little different, the old ones being a polished steel look, and the new ones having an bronze like coating. I found that the finishing work to the piston housing was slightly more refined on the older model, but this could be because of the difference in colour. There are some differences in the barrel assembly. You’ll notice that the pins are miss stamped in the newer model, I did see this on another fde t-pro, so it might be a prevailing change/mistake. Overall I would say the finishing work is close in terms of quality. I wish I had an even older model to add for more reference. None of the firing pin pictures quite show the finish change, but it’s much like the pins in the piston plugs. The old on has a polished steel finish, and the new one is a sort of bronze finish. The bolt head retaining pin has a larger notch in the new one. The bolt heads have slightly different identification marks, but in terms of workmanship they seem pretty close. My new one has some nicks on the bolt face that the old one doesn’t suffer from however. New Old There was a slight discolouration in the finish on the metal parts of the new trigger grouping in places. (New trigger group on top.) Everything else seemed to be pretty similar. The old pistons finish seemed like it had a more grey tinge, while the new ones had almost a green tinge. You might be able to see it in some of the previous photos, but I had a hard time getting a good photo of it otherwise. I’d be interested if anyone else has an old one they wouldn’t mind rating these against in terms of workmanship. Also, if anyone else has a t-pro I’d be interested to know if you’ve found that the internal parts of yours share the same finishing differences as mine. Cheers, and thanks for reading!1 point

-

Very valuable advice, thank you. SBR are not allowed in country where I live and 1301 wasn’t available. Beside, I bought M4 because I wanted M4.1 point

-

Man I don’t think you should have contact there. If open it up, air hose it all, hit everything with brake clean and spray it with a light lube, then darken the area with some sharpie and see if you’re still rubbing. I’d press Benelli, that’s not normal.1 point

-

I would take your trigger group out, put the bolt in and see if it is something further back in the reciever. I am not 100% convinced it is the barrel.1 point

-

1 point

-

Inspect the receiver for burrs, might be some aluminum rubbing. Feel free to pass along photos of my bolts showing no wear, I have thousands of rounds through these. stoeger doesn’t have any idea what they are talking about you will have to be a bit insistent. try and get receipt of purchase from the guy u bought it from?1 point

-

1 point

-

Okay I didn’t notice the bolt wear, that imo is not normal. and your bolt is Cerekote? The M4 bolt is fairly loose and not tight enough to notice less than 1 thou of paint i don’t think…. something may be out of spec there with the wear on your bolt1 point

-

If it ain’t broke… seriously though if it’s running well for 500 rounds so far I wouldn’t be concerned. If the finish is wearing off in spots and you start to see corrosion then I would come back to this. I’m sure Benelli would make it right. in the end these are tools. Even if they are beautiful Italian tools and they are going to take some hits as you use them for their intended purpose. It’s hard to tell from the pics and lighting but is the finish wear on the bolt down to bare metal?1 point

-

1 point

-

I did not need to see this.1 point

-

Thanks for the input. As for release date, looking like the fall at this point. I think I can bring the cost down more but I’m not ready to say what final pricing will be. I’m also able to get the RMR mount down in price as well, much less than others on the market.1 point

-

Got a question for yall. With the newer update design on this, I had to move the bracket to attach at the front mag tube to address some issues of the last iteration. currently I am planning to supply a wave washer for under the mag cap to keep mag cap tension, which does work just fine without issue. Ive also been brain storming alternative methods for the past month with little headway to keep tension on the front mag cap. Older Remington 1100s used to use wave washers for their cap, so it has been done in the past. At this point there doesn’t appear to be another path to take but it hasn’t stopped me from thinking about it day and night for the past month. I’m wondering for those that are wanting this heatshield, what are your thoughts on the wave washer? At this point I think I need community feedback, I don’t think there is another method that will be better than the wave washer (the mounting bracket covers the detent), and it is the last piece of the puzzle stopping me from going into production.1 point

-

I have heard good reviews about the Briley triggers, you have to send them your whole housing so they can fit it for you. I thought about it, but chose instead to go with an OEM aluminum trigger guard, some Wolff trigger group springs for reliability, I didn't change any pull weights. And I lucked up on a Geissele hammer and threw that in. Thats it, I don't plan on doing anything else to it other than shooting it alot to smooth the action out. But if I had to recommend any kit, I'd go with Briley based on the feedback I've heard from people who actually use them.1 point

-

And yet another https://www.speedshooter.com/product/dmw-benelli-speedbar/1 point

-

Here's another version https://cpwsa.com/product/benelli-carrier-rapid-release-tab/1 point

-

That's not OEM, I've always heard it called a "bolt release tab". https://rxarms.com/products/benelli-m4-parts-and-accessories/benelli-m4-bolt-release-tab/1 point

-

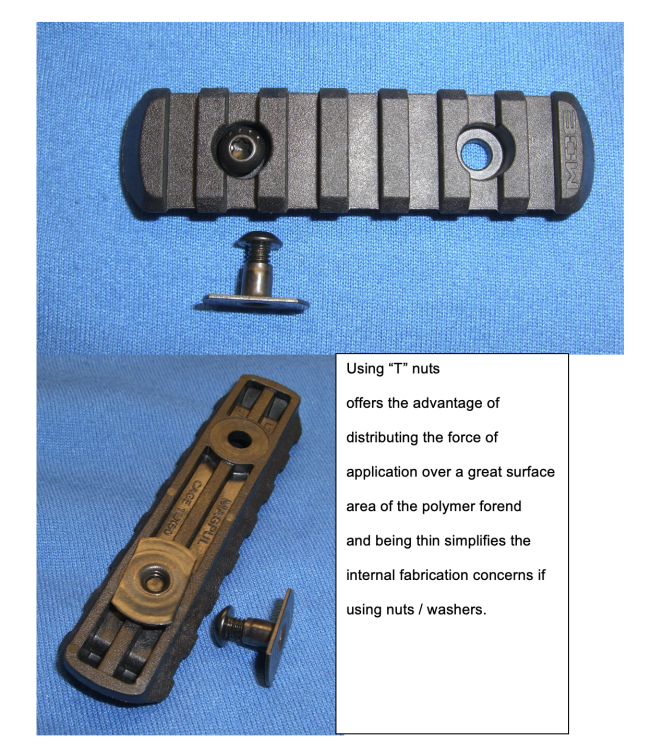

My friend put one on his MAC clone and likes it. I was avoiding it solely because I don’t like how much work it takes to take it off for cleaning and put back on. The factory rail just slides off, because it’s wedged on and tightened when you tighten the magazine tube nut.1 point

-

1 point

-

Still out of work due to my back so I need to move a few more things. I have two Cloud Defensive OWL and full size REIN light and one Micro REIN. All the REIN lights come with Arisaka M-Lok mounts. I will include an extra battery with the OWL and full size REIN and the Micro REIN will come with 4 extra batteries. I only have one charger because the large box I kept my small boxes in got lost when I moved. Asking $300 each. The pick only shows one of each in the pics just because I'm not going to remove them unless someone is interested. And if anyone is wondering, Cloud Defensive is and will continue the lifetime warranty on the OWL and original REIN lights.1 point

-

Question for you Benefactors of Benelli Knowledge... Was there ever a final consensus about obtaining the M3 Entry 5+1 SBS w/ 14.5" barrel and c-stock? (link: http://www.benellidefense.it/products/m3-145-telescopic-stock ) Even just the shorter barrel would be something (w/ proper stamp first, of course...). See pics below. I saw some traffic on a different forum some years ago but nothing else ever since. Are these only "overseas" to MIL/LE, or has someone here stateside cracked the code to legally track down and own one of these unobtainium scatter guns? Any knowledge or information would be great. THX!1 point

-

No idea. Maybe it needed more weight in order for the inertial action to work. I don't know about the new ones, but the old ones had a different recoil setup, than others of the era like M1, but that may only due to mine being folders. I really thought both of my HK folders had 18.5" barrels but I am not positive. As for SBS, I'm not into that really as I prefer extra ammo from extended magazine. So, I think the stock length on the early H&K imported M3T's are about right. As far as having it cut down, there are places that can do that such as Briley. Depending on the barrel thickness, they might be able to rethread it for chokes. Often they end up having to use Rem Chokes instead of Benelli. I think they are thinner.1 point

-

1 point

-

I have run one on my Benelli supernova truck gun for years. It’s the same model, they’re a really cool design. However, I would like a bit more output and it doesn’t allow you to run an extended mag tube but otherwise there are no drawbacks. I really dig the switch, though there is no momentary on/off which I prefer on a gun. The form factor should be imitated by other makers. The concept is rad.1 point

-

1 point

-

Just get both, you won't be disappointed. I am not!1 point

-

As Sly Stone put it, "different strokes for different folks". Some may desire one over the other but I don't think you could go wrong with either, or both.1 point

-

1 point

-

1 point

-

Good questions. I am currently in your potion as well and in the middle of a cool build for my M4 and I am kinda stuck on the trigger issue as well. Not sure if I should send it in or have my gunsmith do a drop in etc. Would love to hear some more insight from some guys on here that are further down the road than us. I know some guys have talked about it, but I just love talking about it even more lol.1 point

-

Love it. Agency does great work. Just wish they'd allow an a la carte to their build.1 point

This leaderboard is set to New York/GMT-04:00

-small.thumb.jpg.7be07b0f70438035828e9da0807d8757.jpg)