-

Posts

356 -

Joined

-

Last visited

-

Days Won

90

Everything posted by RxArms

-

This is a ways off for me mostly due to my small business capacity at this time, but I’m going to be releasing a Benelli M4 QD Sling Mount for the rear collapsible stock in the future. Specifically made for the M4… once I have got the recoil tube for sale, I’ll be moving onto some other M4 products like this.

-

The metal treatment and types of metal they use are cheap… I’ve seen bolt face failures on the Turkish clones, chunks break off the bolt face…… I think if you buy a Turkish clone, replace the trigger group, full bolt carrier at minimum with Benelli OEM parts.

-

PVD aluminum titanium nitride came back, looks pretty killer… It is the only finish that exists out there that checks off all my high quality control boxes; primarily retaining the heat treat on the notches, extremely high corrosion protection, no tolerance interference, high wear resistance. Shout-out to the guy that put me on this path further back in the thread here. I have been told by the finisher that salt corrosion is essentially non existent with this finish… but no formal military testing has been done since it is used primarily for hard use tooling. experienced some minor delays at the machine shop, but this week is full production. Coming soon… (sample pic below that I abused a bit to test the finish… and my canine Apollo)

- 78 replies

-

- 12

-

-

-

Benelli M4 Collapsible stock receiver extension orientation/keying question

RxArms replied to bambihunter's topic in Benelli

I don’t notice the same thing with notches and dead center. For me, the top notches are a bit off center when the buttstock is centered. -

Benelli M4 Collapsible stock receiver extension orientation/keying question

RxArms replied to bambihunter's topic in Benelli

Looks like OEM to me. Quite possible the recoil tube wasn’t installed properly aligned on the reciever. Some collapsible stocks have different tolerances than others. Have you tried your H2O stock on your black gun and vice versa? -

This is easily done by a gunsmith. Just make sure it’s legal in your area to cut a production barrel shorter. in Canada, you can buy a new shotgun with a 12-14” barrel, but you’re not allowed to make your own 12-14” barrel from a longer barrel… typical government.

-

I would say If You want Benelli to take your gun for however many months to replace it and get warranty then go ahead. Otherwise oil it and forget it.

-

Amazing that the machining tolerances are this bad on a new M4 shotgun.. glad you got it sorted.

-

Might seem like an obvious suggestion but make sure your magazine tube is fully seated in the front ring… sometimes it can get hung up on the front mag barrel ring but would be more than 3mm… so I do not think this is the issue… but ya never know. Also, you can try screwing the mag cap down to tighten it, see if you can get it flush. My newest M4 takes some mag cap pressure to seat proper.

-

I have a recent 2020 model. And the detent is loose also, same issue with the OEM charge handle. i haven’t had time to inspect and figure out why the looseness. It could be a variety of things..

-

Ya I’m not saying it’s a bad failing design, I’m saying I think the OEM M4 design is a a better strong design.

-

The rotating buttstock serves a purpose, it has a stationary pin that does not move, this pin is bullet proof when it comes to handling recoil and buttstock strikes. an AR-15 style buttstock only point of contact would be the retractable pin if I am not mistaken. IMO this is a weaker design for a shotgun. The M4 buttstock and recoil tube is a much stronger design. I would imagine the reason clones only use an AR15 style is because of the cost of making the Benelli aluminum cast/milled buttstock and recoil tube was probably too much $.

-

There are only certain items that count towards 922r, the recoil tube is not one of them. Even if it was made in USA it wouldn’t make a difference.

-

They are being produced this week at the shop, the machine shop is busy so it took awhile. Need to laser engrave the stock positions still, heat treat, then send off for PVD which I’m fairly certain I’ll be going with at this time. Looks like maybe end of July is still an accurate timeframe. I’ve done a few tweaks after lots of R&D: -Added a very very minor taper to the end of the notch that holds the retractable pin, this helps to stop the buttstock from rotating out. This mod took the longest to sort out…. -I added a notch to be able to remove the spring if ever needed, the notch also doubles as a visual placement aid, to know where the top position of the tube is in the reciever, final adjustment should be done with buttstock. -added a chamfer to the recoil pin notches. This was a late change I made recently, after extreme abuse testing quite a few prototypes, i noticed the metal was susceptible to deformation and expanding higher (I was literally banging buttstock on the gun against cement floor). Further investigating led me to looking at OEM example again and also extremely abused the OEM (which also deformed), this is when I noticed a chamfer, which has an important end use. If the metal deforms even the slightest, the chamfer stops the deformation from rolling up and changing the outside dimensions of the tube. It also increases strength of that particular spot, an angled contact point is always stronger. it’s the little things I like to make sure are not overlooked!

-

Yes you need a new recoil tube, you can buy an OEM 3 position, or perhaps wait a few weeks for the Benelli M4 6 position recoil tube I’ll be releasing soon! if swapping it out is too much for you to take on, I’m working with a guy here on this board that can help you out with that in the USA.

-

New M4, is this a regular amount of bolt tail peening?

RxArms replied to slobbergoat's topic in Benelli

Yes it is normal, you don’t need to do anything, but it back in and shoot it! -

Longer barrel will swing better too I guess, something I never thought of. Better for hunting for objects that are in the sky!

-

Yeah… not sure how much difference an extra 10” length will really make, I mean how far away are the drones they are shooting at that a 28” barrel will really make a big difference? Why not just put a turkey choke on an 18.5” barrel? *shrug*

-

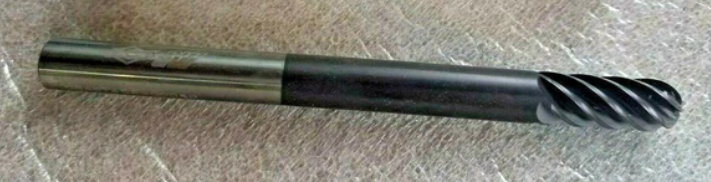

I've sent off a sample for PVD using a Titanium Aluminum Nitride (TiAlN) coating. Looks like a really nice tech to me, costs a bit more per piece, but I believe M4 owners would appreciate the premium finish it provides. It will be the same colour as this example here. TiAlN is a coating used on cutting inserts, end mills, and drill bits, intended to resist high heat (not applicable here), give extreme hardness, provide lubricity and corrosion protection. Should pretty much last a lifetime...

-

Speaking of Benelli QC, down at the machine shop finalizing details on this 6 position tube, and we have 2 collapsible buttstock a here. 2020 is left, 2021 is right. There is an obvious difference with QC on these, 2020 production tube opening has a chamfer, 2021 doesn’t. 2020 fits and locks better on the OEM tube and the 6 position, 2021 doesn’t lock in as good with OEM and with mine. 2021 is also WAY tighter on the tube (for both) Benelli seems to have switched manufacturers in 2021. And it isn’t better..

-

I've fired my new M4 a bunch of times the past few weeks, nothing wrong with it at all, except for perhaps a little sloppy detent pressure in the bolt, that holds the charging handle, other than that, it is great. My old M4, also nothing wrong with it...

-

Backorders, they are risky business. I am in control of my own production and finishing, and even with this, I rarely do backorders unless I am VERY confident of a ship date. I recently put up backorders for the Ti charging handle and even gave an extra 2 weeks past what I am expecting for shipping date as I never want to be the company that goes over the ETA. Backorder mess up can make or break vendors IMO.

-

Is the M2 latch a simple drop in part? The link above points to a 20g latch, does that matter? Edit: found the answer (yes), here…

-

I tracked down a PVD (physical vapour deposition) coating service in Canada. However, the catch is there is no interior coating can be applied due to the technology (it will adhere only to the exterior). this type of tech is used on industrial tool punches and machining cutters, so a very hard, lubricated, thin and corrosion resistant coating. im willing to go down this path, but the inside will not be able to get any coating. They estimate 1.5” or so on each end ID of the tube will receive the coating. The rest will be raw steel. my thoughts on it, even if I went black oxide, the finish on the ID would most certainly be removed in short order due to the spring and plunger rubbing against the inside diameter. I would imagine it would only take 50-100 rounds to completely rub off any black oxide coating leaving bare steel exposed. so I am considering the premium PVD coating which is very low in thickness (about 3-5 micron) and can provide probably a lifetime of corrosion and wear resistance on the exterior. It is a dark grey/black colour they refer to as Anthracite. Would like input, if any, from you all on your preference. (Black oxide OD and ID vs PVD exterior raw interior).

-

Yes it had crossed my mind, but I’d like to keep things as realistic as I can. But ya it has crossed my mind to use shipping/handling/processing as a means to increase the price. With all this said, for this batch, I’m happy with the price I’m able to offer it at.