Leaderboard

Popular Content

Showing content with the highest reputation on 12/22/21 in all areas

-

^^^^Doesn't surprise me at all that your apparent issue was the spring. When you get down to the last couple of rounds if the spring tension or power remaining is not sufficient enough to throw next the shell well back onto the carrier, it stops up the gun. Personally, I stay away from FFT supplied stuff.2 points

-

If that’s a Tacstar side saddle, it’s a notorious piece of shit that will definitely squeeze the receiver if tightened too much. Not tightened enough and it falls apart. Then it starts scratching up your receiver. Any aftermarket shell elevators in use? I’d take the magazine tube apart and clean it well inside. Do not apply oil inside the magazine tube at all. I’d recommend making a polishing jig for the magazine tube. I put a 12 gauge cleaning rod in my drill gun, then wrap fine steel wool around a 12 gauge chamber brush. Then go to town up and down the inside of the magazine tube for 5 minutes. Clean out the residue and admire the mirror finished magazine tube. Note the difference in sound once you reinstall the spring and follower. The magazine spring won’t be fighting the resistance inside the magazine tube as much so that it can deliver more of the spring energy to loading shells onto the elevator. This is particularly important when it is the last round or two being loaded from the magazine. The polishing can be done on steel, titanium or even the Briley carbon fiber magazine tubes.2 points

-

1 point

-

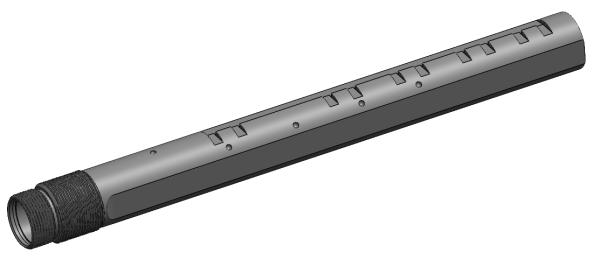

There is also an older 2 position receiver extension. No idea where they originated from. I received some from Numrich arms back around 2012.1 point

-

No problem. Thanks for letting me know.1 point

-

Interesting, I bought mine on Saturday, shipped Monday. This is not going to be an Amazon prime type experience though. Small company making a few one off parts for Benelli Nutz... Mine is supposed to be here Friday.1 point

-

1 point

-

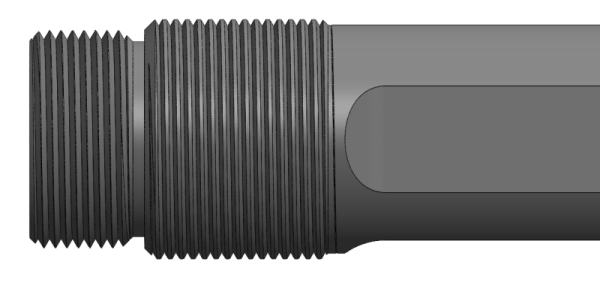

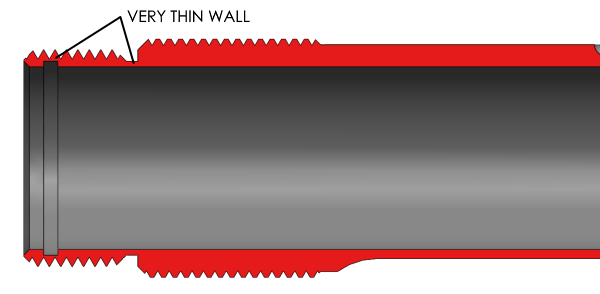

Yeah, he’s not right. That finish is microns thick. I’ve filed thru it a bunch doing loading port jobs. That handle has much more clearance than that in its normal position. When watching the receiver in slow-mo, you can see the receiver flex during recoil. If it was that tight, it would be making contact. If you try, you can force the handle past the detent and end up rubbing the receiver. This is the issue TTI had with their original bolt knobs. They were being over-inserted by the end user or being pushed in during transport. It caused a lot of damage too. I’m not a fan of the 3/4” size, but that’s just my personal preference. I don’t care for knurling on it either. Didn’t care for it on the Carriercomp one either. I’ve settled in on the new TTI model. Pro Tip:If you’re shipping guns or transporting in a case you should remove the bolt knobs.1 point

This leaderboard is set to New York/GMT-04:00