Leaderboard

Popular Content

Showing content with the highest reputation on 12/20/21 in all areas

-

If that’s a Tacstar side saddle, it’s a notorious piece of shit that will definitely squeeze the receiver if tightened too much. Not tightened enough and it falls apart. Then it starts scratching up your receiver. Any aftermarket shell elevators in use? I’d take the magazine tube apart and clean it well inside. Do not apply oil inside the magazine tube at all. I’d recommend making a polishing jig for the magazine tube. I put a 12 gauge cleaning rod in my drill gun, then wrap fine steel wool around a 12 gauge chamber brush. Then go to town up and down the inside of the magazine tube for 5 minutes. Clean out the residue and admire the mirror finished magazine tube. Note the difference in sound once you reinstall the spring and follower. The magazine spring won’t be fighting the resistance inside the magazine tube as much so that it can deliver more of the spring energy to loading shells onto the elevator. This is particularly important when it is the last round or two being loaded from the magazine. The polishing can be done on steel, titanium or even the Briley carbon fiber magazine tubes.6 points

-

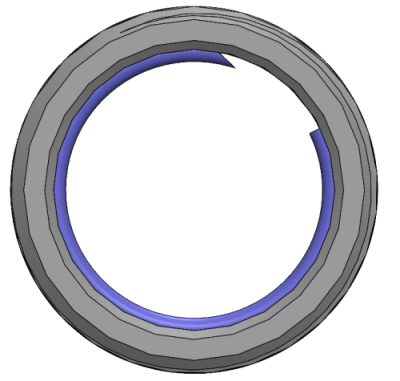

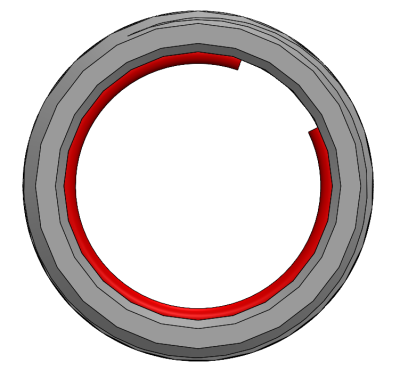

Here's the dimensions for the original flexible retaining ring: I did briefly investigate a sourcing for aftermarket replacement but it appears it doesn't conform to any ANSI or DIN specifications. So chances of finding this off the shelf is slim. I did also look at either making my own out of spring steel with an angled cut (purple ring) to aid in removal or take an original ring to the grinder. Basically stick a pick tool in the corner and pry it off like shaft snap ring.2 points

-

Looks horrible with that Carlson breaching choke, imo. Too cramped, aesthetically. The textures are all over the place too. The Nordic is the way to go1 point

-

1 point

-

I ordered a silicone cook top pad from Amazon for around 5 bucks prior to starting this project and a set of nylon 5.5" vise jaws for around 7 bucks. I was able to use the little 7" x 7" silicone pad to assist in turning the magazine tube. About 7-8 minutes with small Benzomatic torch did the trick. I kept the torch moving around the magazine tube and tested being able to rotate it every minute or two. It moved a about a quarter of a turn after about 7 or 8 minutes then stopped. I hit it with the torch again for about 2-3 more minutes and then it slowly rotated off. The silicone cooktop pad from Amazon made this much easier. If you try your recoil tube be prepared for about 30-45 straight minutes of heat. Best of luck!1 point

-

I was kinda in a hurry to behonest .Or I would have got a number 30 minute lunch1 point

-

Some of the tubes can be tougher to remove than others. I guess it depends how much thread locker they used. Typically you’ll see the tube rotate a few degrees and then stop. More heat is needed to get it to move a little more, then seize. Repeat this several times and eventually it’ll come free.1 point

-

No lady just got one from a bin and charged me.So there out there .Then paying fft $401 point

-

1 point

-

1 point

-

1 point

-

Thanks, I am aware they have those in stock for $22, MGW is $5. Not that I can't afford it, I just think their price is excessive.1 point

-

Not promoting…but sounds like the same price your waiting on, and it’s in stock if your source is out it’s an option. $22 https://freedomfightertactical.com/products/benelli-oem-flexible-ring-70071?_pos=1&_sid=59ef71359&_ss=r1 point

-

While it does make loading a bit smoother/easier, I decided to forgo it for the FFT bolt release button. I basically gave up some loading ease for cosmetics. To my delight the spring didn't hang up on the receiver. I thought it was going to be a tight fit but everything worked well. I cycled dummy rounds through it 2x - loaded the mag tube full each time. No malfunctions.1 point

-

It’s solid too. I use it in conjunction with a vice. You just press the tool into the plug with the jaws and index the hole for the pin so that it drops right out as soon as you have enough tension on it. Then release the jaws and the internals slide right out. Reassembly is just as easy, you just index the pin hole horizontally instead so it doesn’t just drop right thru.1 point

-

I see a crossbolt going through a receiver. This is a no no in my book. You could be pinching the receiver or distorting it in a way that is causing retardation of the carrier's movement. I am not sure this is the problem, but when someone has an issue with a gun as proven as the M1014, and it's not in factory configuration, I opt to return it to such, operationally, before further diagnosis. Further, the mag tube/spring comment above is very on point, as well.1 point

-

Went to the range yesterday. Everything worked great. No problem loading 8 rounds. Not FTF. Ghost loaded 10 rounds. Boy was that fun? Action shot of my buddy who emigrated from Scotland. He sent the photo to his friends in Europe titled" Sunday morning Merica!". You can see the flash pattern from the breacher choke.1 point

This leaderboard is set to New York/GMT-04:00