-

Posts

353 -

Joined

-

Last visited

-

Days Won

10

Everything posted by Jolly Roger

-

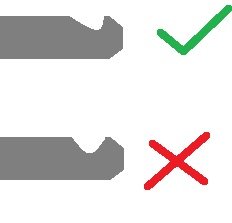

Was the first bolt that flew out an OEM? None of these after market bolt handles seem to be cut right, wrong angle, too deep here or too shallow there...Mostly all of them far outweigh the OEM handle. An example of a comparison between the oem vs an after market handle here in this picture below. (my drawing from another thread complaining about AM handles)

-

The rear sight on the M4 is a royal PITA to take off. The bolts are staked after assembly.....just sayin..

-

Totally agree, Im a field stock guy myself.?

-

-

Its not terribly hard to modify/shorten LOP on your OEM stock. Plus you get a sense of accomplishment by doing it yourself. A Dremel tool is your best friend in doing mods like this. Here are a couple pics of my M3 before and after I chopped her down. Green tape and a exacto blade made a nice straight line to follow, after that I decided to just reuse the oem but pad so I had to Dremel a step/recess for it to fit. (picture was taken before final sanding was done) You could also use a limbsaver pad with an adapter plate as well. Here is a link to that M3 project if youre interested....it was a fun build. https://forums.benelliusa.com/topic/21328-some-m3-love/?tab=comments#comment-143712

-

I even tried making my own mechanism that kept the original button un-drilled or inducing any accidental twisting of the button.. https://forums.benelliusa.com/topic/21323-i-made-a-thingy/?tab=comments#comment-143672 In the end, the original button seems to work better than anything. Its small and snag free.

-

Thought about this thread when you said that.. https://forums.benelliusa.com/topic/21634-enhanced-bolt-release-options-for-m1014/?tab=comments#comment-146250

-

Production problems, quality issues, price point issues, reliability issues, legal issues....

-

..but their site is still up, just that one product is missing....hmmmm I could speculate a few situations but Im conspiracy minded...?

-

Im sorry, I got confused with a different brand. My bad.

-

Stranger Danger the man! ?

-

fan boy.?

-

double post...

-

I really liked Daves Metal works. I think he is only asking 90 bucks for a 7 rnd tube. Its metal, but strong.

-

Yep, when you have all three in front of you its a no-brainer. The poly one is...well its plastic. The OEM aluminum one is rough and crudely cast...The A&S is high quality and precision made. It puts both the plastic and oem aluminum guards to shame. ****************************************************************************** Plastic guard kinda reminds me of Glock (and thats being kind) OEM aluminum guard reminds me of Hi-Point A&S guard = Full custom 1911 ...and Im not a A&S fanboy, just calling it as I see it. Honestly I dont care for the built in ramp on the A&S guard, I think its useless and looks dumb...

-

In my own personnel experience, the thread locking agent begins to smoke just a bit before its ready to be overcome. I too was very afraid of overheating my parts, but found this common sign to be pretty universal when dealing with there loctite. I've molested 6 M4's now... mag tubes and recoil tubes.

-

A bit of high temp black RTV silicone applied to the sling plate stops the rattle. Just take it off and clean it, put a little bit on with your finger and reassemble it with the snap ring. Center it with the barrel and let it set for a night. You can take a Q-Tip and rid any extra RTV that may squeeze out making for a nice tidy job. Its completely unnoticeable when done.

-

I think I saw that gun on a video game once....

-

Dont forget to clean the whole thing after your done. ?

-

ADHESIVE SANDPAPER (fine grit) Cut a small 1inch X 2inch piece and stick it to a dummy round. Thumb it in and out, dont press it all the way in as to let it go past the shell stop. Doing this will create a polished indention on the shell stop lip. Stop sanding when your satiated.? and dont sand all the way through it...lol! Smooth as butter when your done!

-

The Hayl Rail is junk brother. Dont waist your money...

-

Great videos! Informative Thank you for sharing.

-

I have a DMW 7 round tube with a upgraded spring installed, cant remember if it was a CC or Wolf. I can only fit 6 rounds of 2 3/4 inch shells in it. My shells measure just over 2 1/4 inches each. The seventh shell is just a few mm from going in the mag tube. Solution: Cut a few coils off the spring and retry. I ended up cutting about 6 coils off and the 7th rnd now fits into the mag tube. So far, so good. When I load 1 shell into the mag (simulating a last rnd) it loads into the bay and chambers every time. Sometimes adjusting the elevator alleviates problems with the last rnd not loading into the bay as well.